Repower your fleet with replacement gas turbines

Regardless of your original equipment manufacturer, GE has the latest aeroderivative and heavy-duty gas turbine repowering technology to make your units economically viable again.

Our proficiency in gas turbine replacement and flange-to-flange (including plant integration) solutions for aeroderivative (aero), industrial, and heavy-duty gas turbines from different OEMs–including Siemens, Westinghouse, Pratt & Whitney or Rolls-Royce–will position your plant to be competitive in the future.

Repowering is a beneficial solution for plant operators looking to reduce both upfront and operating costs, as well as emissions. Replacement gas turbines from GE allow your plant to achieve higher output and efficiency, which leads to lower $/kWh, and these newer gas turbines will help keep your plant more environmentally compliant.

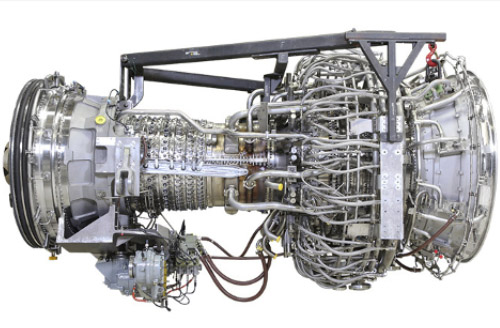

With their origins from our fabled aviation technology, GE’s aeroderivative gas turbine portfolio features highly flexible and mobile technologies for use in a wide variety of applications. Our aeros are trusted and proven the world over and have a wide range of characteristics that make them a great choice for energy providers.

Power range:

22 – 34 MW

Range of efficiency (simple cycle):

38%

Hydrogen capability (% volume):

5% (DLE), 75-95% (SAC)

Emissions range:

DLE NOx of 15 ppm

Battery storage solution available:

Hybrid EGT solution

Operational flexibility:

- Start time/ramp up:

5 min start capable to maximum power

Synchronous condenser:

Clutchless

Power range:

45 – 55 MW

Range of efficiency (simple cycle):

>41%

Hydrogen capability (% volume):

5% (DLE), 30-35% (SAC)

Emissions range:

25 ppm NOx (SAC), 15-25ppm NOx (DLE)

Battery storage solution available:

LM6000 battery Hybrid EGT

Operational flexibility:

- Start time/ramp up:

5 min start capable to maximum power

- Peak performance:

Up to 5 MW

Synchronous condenser:

Clutched or clutchless

Power range:

117 MW

Range of efficiency (simple cycle):

44%

Hydrogen capability (% volume):

5% (DLE), 30% (SAC)

Emissions range:

DLE NOx of 25 ppm NOX

Battery storage solution available:

Hybrid EGT solution

Operational flexibility:

- Start time:

10 min start capable to maximum power

- Ramp up:

<60 sec to 50% of power

- Peak performance:

Up to 8 MW

Discover how replacing gas turbines with new GE aeroderivative gas turbines is helping to keep South Australia powered, working alongside renewable energy resources for a sustainable energy future.

power-output increase with the LM2500+

power increase with combined repowered turbine and LNG

"As the sole distributor of electricity in Jamaica, we see the use of LNG as resulting in greater stability in the price of electricity for our customers. By replacing a 19-year old unit with GE's advanced aeroderivative technology, we’ll be able to deliver more efficient power to our people, our businesses, and our critical facilities."

Joseph Williams

Senior Vice President of Generation, JPS

Integrating the LM2500+ gas turbine, GE Power Services signed an agreement with JPS to modernize its generation equipment and provide expert advisement at its Bogue Power Station in Montego Bay.

With GE’s latest aeroderivative gas turbine technology, you can make your units more economically attractive and prepare your plant for its future energy needs through efficiency, output, and emission improvements.

The rapid growth of renewables is providing more opportunities for aeroderivative units to prove their worth as peakers, allowing you to benefit from grid balancing and ancillary services by replacing your current gas turbines.

GE’s extensive experience in cross-fleet solutions means that whether you own a Siemens heavy-duty gas turbine or Rolls-Royce aeroderivative gas turbine engines, we will work with you to tailor the scope of the cross-fleet repower that suits your needs, maintaining as much of your existing infrastructure as possible—like balance of plant, switch gears, generator, etc.—to lower the cost.

Offers used/refurbished replacement aeroderivative gas turbine packages improved by GE’s engineered systems, components, upgrades and digital solutions.

How TruePackage works:

Advantages:

✓ 30% cost reduction compared with a new installation

✓ One-year OEM warranty and equipment performance guarantees

✓ Delivered in eight months or less

✓ Equipment selection and refurbishment plan driven by installed cost

✓ OEM certification can improve financing options and insurance premiums

✓ GE and WattStock co-located in Houston, TX service center

Our gas turbine retrofit program can replace your gas turbine with a new or refurbished GE aeroderivative turbine within your existing package.

Benefits:

✓ Output (gen. output, gross, kw) guarantee

✓ Guaranteed HR, btu/(kW*h)

✓ NOx, Ref % O2, ppmvd guarantee

✓ CO, Ref % O2, ppmvd guarantee

✓ Full package and engine warranty

✓ Reuse of BOP equipment

✓ Current with all new production design and technology