Powering South Africa's Economic Growth

The right solution to help meet South Africa’s energy security and decarbonization ambitions

To help ensure sustainable, affordable and reliable power, South Africa needs an electricity market design which allows early-stage investment into renewable, lower carbon technologies, and the expansion of the electrical grid system. This has the potential to drive industrialization, enable new employment opportunities and raise productivity for economic growth.

Lower-carbon solutions, such as renewable energy supported by gas power, can contribute to a more decarbonized energy future while providing reliable power.

GE has a solution to support South Africa’s anticipated growth in renewable energy and its transition to a lower carbon energy future: The 9HA gas turbine. Reliable, proven, hydrogen-capable and flexible to complement intermittent renewable energy sources, this powerful gas turbine can help keep the lights on and contribute to a healthier environment for the people of South Africa for many years to come.

White paper

Accelerating South Africa’s energy transition with gas power and renewables

Access to reliable, affordable and sustainable energy is needed to transform South Africa’s economic development. As the country experiences electricity demand growth, renewables and gas provide a powerful combination to help ensure reliable power supply and accelerate the country’s decarbonization efforts.

More power, cleaner power, flexible power

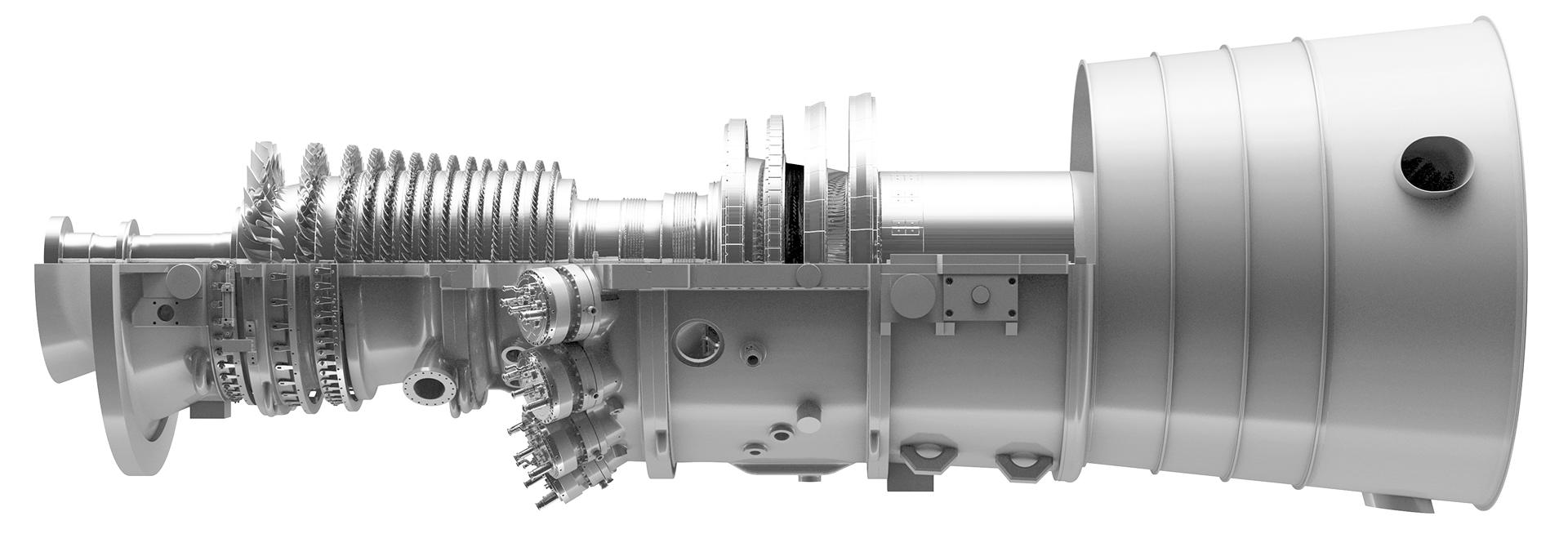

Introducing the 9HA gas turbine

Highly reliable and efficient to run, the 9HA gas turbine can deliver more than 64% efficiency in combined-cycle operation.

Our gas turbines can also run on a variety of liquid and gaseous fuels, including fuels that contain hydrogen, making them a good solution to help meet South Africa’s current and future decarbonization goals. The 9HA gas turbine’s operational flexibility can help the country meet its ambitious renewable targets by providing firm, on-demand power that can be ramped up or down quickly to complement more variable supplies of renewable energy and stabilize the grid. The 9HA fleet also has experience operating in the harshest environments, so customers can be confident in having security of supply for their end users.

The robust, proven 9HA gas turbine delivers many benefits:

- Lowest emissions in the industry

- Record-breaking turbine efficiency

- Industry-leading operational flexibility

- Hydrogen-ready

- Tried and tested, proven technology

- Modular configuration that reduces installation and cost

- Simple air-cooling architecture for easy plant integration

Technology in motion

See our HA gas turbines in action

Coal-to-Gas transition in Vietnam

Coal-fired power generation powers more than 50% of the total energy supply in Vietnam. As the country charts a rapid path to more sustainable energy sources, Vietnam will need the flexibility, output, and efficiency of gas power.

GE's HA technology leadership

GE’s 9HA high efficiency, air-cooled gas turbine is one of the industry leaders among H-class offerings, and now the 9HA gas turbine is at the heart of GE's most efficient combined-cycle power plant.

The first 9HA.02 in Thailand at Bang Pakong gas plant

GE’s 9HA high efficiency, air-cooled gas turbine is one of the industry leaders among H-class offerings, and now the 9HA gas turbine is at the heart of GE's most efficient combined-cycle power plant.

Helping EDF meet Europe’s energy goals

In response to Europe’s goals of lowering emissions and conserving natural gas, Électricité de France (EDF), one of the world’s largest utilities, is utilising GE’s 9HA turbine for their Bouchain plant.

A leader in H-class technology

Providing energy efficiency and fuel savings

The highly efficient, air-cooled 9HA gas turbine is an industry leader in the H-class space, delivering exceptionally low lifecycle costs per megawatt.

Cost-efficient conversion of fuel to electricity

The 9HA gas turbine is an industry leader in the H-class space, delivering exceptionally low lifecycle costs per megawatt. Over its lifecycle, total cost of ownership of the 9HA gas turbine is 5% lower than GE’s F-class—driven by lower capex, simplified configuration, decreased fuel cost from industry-leading efficiency, and extended maintenance intervals and reduced maintenance cost for H-class technology.

Industry-leading operational flexibility

GE’s H-class combined-cycle power plant has industry-leading flexibility and full combined-cycle plant load in less than 30 minutes, making it a great complement to intermittent renewable sources.

Lowest emissions in the industry

The 9HA’s DLN 2.6e combustion system offers a step change in performance, emissions, and fuel flexibility. The DLN 2.6e maintains many of the elements of GE’s DLN 2.6+ combustion system and introduces advanced premixing for reduced NOx emissions while enabling high plant efficiency. Its advanced premixer enables expanded fuel flexibility to operate on both “rich” and “lean” gaseous fuels, a 50% hydrogen (H2) capability with a technology pathway to 100%, a gas turbine turndown to more than 30% load, and an optional park mode at 7-15% load, further reducing customers’ operating costs.

Proven technology

Installing a gas turbine in your plant shouldn’t involve any unknowns. Across our HA fleet, each original turbine is put through several rigorous full-speed, full-load (FSFL) validation test at our Greenville, South Carolina facility. This $200 million investment allows us to push the units beyond real-world conditions—running the turbines at 110% of their rated speeds at load and replicating the harshest conditions. This type of extreme testing is possible because the gas turbine operates independently from the restriction of the power grid, enabling a much wider testing envelope than an on-grid facility.

Industry recognition

GE has been previously recognized by a 3rd party for setting two world records for powering the most efficient plant in an H-class combined-cycle (CC) application: 63.08% gross CC efficiency at Chubu Electric’s Nishi Nagoya power plant in Japan (7HA, 60Hz), and 62.22% net CC efficiency at EDF’s Bouchain power plant in France (9HA, 50Hz).

In 2021, Southern Power Generation’s 1.4 GW Track 4A power plant, a natural gas-fired power plant in southern Malaysia—equipped with the first commercial GE 9HA gas turbines—was recognized by POWER Magazine as their “2021 Power Plant of the Year” and by Diesel & Gas Turbine WORLDWIDE as “Power Plant of the World”, a meaningful model for balancing climate awareness, energy affordability, and reliability.

In addition, GE’s HA technology was adopted at China Huadian Corp’s Juliangcheng plant to help accelerate the retirement of existing coal-fired capacity and replace it with new, highly efficient combined-cycle gas turbines—an important role that earned POWER Magazine’s “ReinventionAward”.

Global experience

GE’s HA technology has been operating in our H-class fleet for ~7 years and has accumulated 1.9M operating hours (as of July 2023). GE’s HA portfolio is the world’s fastest growing fleet in its class with more than 145 gas turbines ordered by 50+ customers across 24 countries.

Simplified modular construction

GE’s H-class gas turbine packaging leverages a lean, modular, prefabricated approach engineered to achieve:

- Easier installation that reduces gas turbine installation schedule by up to 8 weeks

- Simplified unit maintenance with easy access to the gas turbine accessory systems

- Increased onsite safety

- Lower project risk

- More efficient inspection and maintenance

- Reduced gas turbine installation labor (about 13K man hours)

The gas turbine enclosure features modular architecture with valves, piping, and electrical systems packaged into stackable modules, which allows for simultaneous installations as well as reduced safety concerns and delays due to interfering tasks.

Cost-efficient imports to bridge the energy gap quickly

Reliable gas to power

A notable example from GE is the Porto de Sergipe power plant, an integrated gas-to-power project built on the coastal state of Sergipe in Brazil. The power plant is capable of generating 1.5 GW, or around 15% of the Northeast region’s power needs. It is the largest combined-cycle, gas-fired power plant in South America, enabling Brazil’s transition to lower-carbon energy.

The project required engagement with a wide range of stakeholders: thousands of local workers, community leaders, local businesses and government—with the 3,000 strong labor force, up to 60% of whom were locals. GE set up social programs and training centers where workers could learn on the job and obtain certificates that would serve them well beyond the project’s construction.

The project features three 7HA.02 gas turbines, together with a steam turbine and three heat recovery steam generators (HRSG). GE provided full engineering, procurement, and construction (EPC) of the gas power plant and grid construction, as well as associated grid interconnection systems (33 kilometers of overhead power lines and a 500kv substation) in addition to controls software and analytics and a 25-year Operations and Maintenance (O&M) service agreement. This integrated approach can be replicated in South Africa.

Hydrogen-ready gas turbines

Supporting South Africa's decarbonization journey with hydrogen

GE is the world leader in the application of fuels containing hydrogen in gas turbines. Over the last 50 years, our turbines have logged more than 8.5 million operating hours running on hydrogen with concentrations of up to ~100% (by volume).

Following a strategic cooperation agreement (SCA) signed among Egyptian Electricity Holding Company (EEHC), GE, Hassan Allam Construction, and PGESCO, a GE LM6000 aeroderivative gas turbine was safely and successfully run-on hydrogen-blended fuel for the first time in Africa. GE recently announced new HA-powered pilot projects focused on demonstrating power plants capable of operating on hydrogen.

Decarbonizing power generation

GE’s carbon capture experience

GE is at the forefront of carbon capture technology development, exploring proven, scalable solutions that can decrease power plant CAPEX and OPEX. Integrating carbon capture and sequestration technologies into society depends on the contribution of many focus areas. The good news is, it's already in motion. Watch our webinar to learn more.

Enhancing operational performance

Enabling reliable, efficient and economical operations

South Africa’s successful transition to a new decarbonized landscape will require that plant operators not only have the most efficient technology, but also the right digital tools to help improve performance and drive operational priorities across the fleet, regardless of OEM.

With over 1,000,000 installed MW in more than 120 countries, GE’s maintenance programs help customers balance performance and risk while getting the most out of their gas plant assets. The wide range of coverage includes outage duration, availability, reliability, emissions, monitoring and diagnostics, and maintenance performance.

GE is also recognized as an industrial software leader trusted by hundreds of innovative power generators around the world. To stay economically viable during the energy transition, advanced software to optimize plant performance, efficiency, flexibility and reliability starts with accurate data and analytics.

Partners for progress

GE’s 9HA gas turbine projects around the world

GE’s HA gas turbines are the technology of choice for many of the world’s power providers. Learn more about some of them here.

-

France: Setting performance efficiency records for EDF

-

UAE: Breaking efficiency barriers for SHIPCO

-

Greece: Delivering high efficiency for Agios Nikolaos

-

Poland: Stabilizing the local grid and lowering emissions for PGE

-

Israel: A more sustainable, flexible solution for Orot Rabin

-

Malaysia: Enabling Pasir Gudang's transition from coal to gas

-

Thailand: Enabling Pasir Gudang's transition from coal to gas

-

France: Setting performance efficiency records for EDF

-

UAE: Breaking efficiency barriers for SHIPCO

-

Greece: Delivering high efficiency for Agios Nikolaos

-

Poland: Stabilizing the local grid and lowering emissions for PGE

-

Israel: A more sustainable, flexible solution for Orot Rabin

-

Malaysia: Enabling Pasir Gudang's transition from coal to gas

-

Thailand: Enabling Pasir Gudang's transition from coal to gas

France: Setting performance efficiency records for EDF

After a 45-year partnership, GE and France’s EDF unveiled GE’s most efficient combined-cycle power plant. With an efficiency of 62.22%, the Bouchain plant runs on GE’s 9HA gas turbine, helping to deliver a world record, and setting the stage for the next-generation 9HA model—the 9HA

600 MW

combined-cycle capacity for the Bouchain plant

efficiency rating from EDF/GE partnership

"

"By commissioning this new generation thermal plant with GE, EDF demonstrates its intent to apply the best available technologies on the market to make its French thermal power plants more energy efficient, all while supporting the energy transition."

Jean-Bernard Lévy

CEO of EDF

UAE: Breaking efficiency barriers for SHIPCO

Owned by the Sharjah Hamriyah Independent Power Company (SHIPCO), the 1.8 GW Hamriyah Independent Power Plant (IPP) is a key component of the Sharjah Electricity, Water and Gas Authority’s (SEWA’s) 2030 Roadmap to boost installed capacity to 4,600 megawatts. GE’s HA technology is expected to help make the Hamriyah project the most efficient power plant in the Middle East’s utilities sector once it is complete.

4M tons

in projected carbon dioxide emission reduction compared to current levels

25 years

of service agreements

"

"The delivery of GE’s H-Class gas turbines at the Hamriyah Power Plant marks a significant milestone for the region’s utility sector. It brings us one step closer to delivering on our commitment to provide on-demand, affordable power to meet the needs of Sharjah, and to reduce the environmental impact of power generation activities in the emirate."

Al Suwaidi

Chairman of SEWA

Greece: Delivering high efficiency for Agios Nikolaos

One of the largest natural gas-fired combined-cycle power plants in Europe, Agios Nikolaos uses GE’s HA gas turbines. The Voiotia plant will produce up to 826 MW, and alongside its thermal efficiency of 63+%, GE helps make it one of the continent’s most efficient power plants.

thermal efficiency rating of the Voiotia plant

1,000,000+

proven operating hours of HA gas turbines

"

"GE’s technology, combined with the engineering and construction expertise of our EPC business unit METKA, will bring this large investment to life and help contribute significantly to Greece’s energy security and stability."

Evangelos Mytilineos

President and CEO of MYTILINEOS

Poland: Stabilizing the local grid and lowering emissions for PGE

PGE ordered two GE 9HA gas turbines for its Dolna Odra power plant. When the facility is operational, its two high-efficiency/lower-emission turbines will help stabilize the regional grid—which relies on renewables—and is projected to curb CO2 emissions by an annual two to three million tons.

1.4 GW

power equivalent of one million Polish households

2 - 3 million tons

projected annual reduction in CO2 emissions

"

"PGE’s investments in modern coal-based energy are enhancing the country’s energy security and facilitating a gradual replacement of old capacities in the system. GE’s turbines boost us by nearly one-third in efficiency and bring the country’s CO2 emissions down by some 2.5 million tons."

Henryk Baranowski

PGE’s Chief Executive Officer

Israel: A more sustainable, flexible solution for Orot Rabin

of Israel’s electricity capacity delivered

1260 MW

of power produced

"

“Adding a second 9HA.01 gas turbine from GE for our modernization project further ensures we are investing in industry-leading technology to help meet the growing needs of the businesses and citizens in Israel. Our efforts will change the way power is delivered in the country.”

Ofer Bloch

President and CEO, Israel Electric Corporation

Malaysia: Enabling Pasir Gudang's transition from coal to gas

Steady economic growth in Malaysia has called for a steady increase in power capability. GE Gas Power partnered with Southern Power Generation (SPG) in the city of Pasir Gudang, Johor to meet this energy challenge for the Track 4A power plant - as well as to address the country’s spreading decarbonization effort. Track 4A was declared POWER Magazine’s 2021 Power Plant of the Year.

1,440 MW

total plant-output capacity

3 million

Homes able to benefit from Track 4A

"

“From a longstanding relationship with GE, we trust its HA technology and are proud to see hard work and efficiency achieve the start of GE’s first-ever commercial-operation 9HA.02 gas turbines, despite the COVID-19 pandemic, without having to compromise on health and safety.”

Dato’ Haji Nor Azman bin Mufti

Chairman of SPG

Thailand: Enabling Pasir Gudang's transition from coal to gas

The plant began operations in 2022 and is delivering approximately 1,400 MW to the national grid. The project will help Thailand achieve its goal of securing 57,460 MW of power generation capacity by 2036 while supporting the country’s decarbonization goals of reaching carbon neutrality by 2050 and net-zero greenhouse gas emissions by 2065.

3 million

Homes to benefit

1,400 MW

Power on the grid

"

“This project is in response to the government’s commitment to the retirement of less efficient and older plants, to be replaced with new gas-powered highly efficient combined-cycle capacity as a solution to reduce emissions and increase the reliability and flexibility of Thailand’s power system. We trusted GE as an energy player with future-proof technology to help us provide more reliable and more sustainable power for our population now and in the following years”

Prasertsak Cherngchawano

EGAT Deputy Governor - Power Plant Development and Renewable Energy