Overview

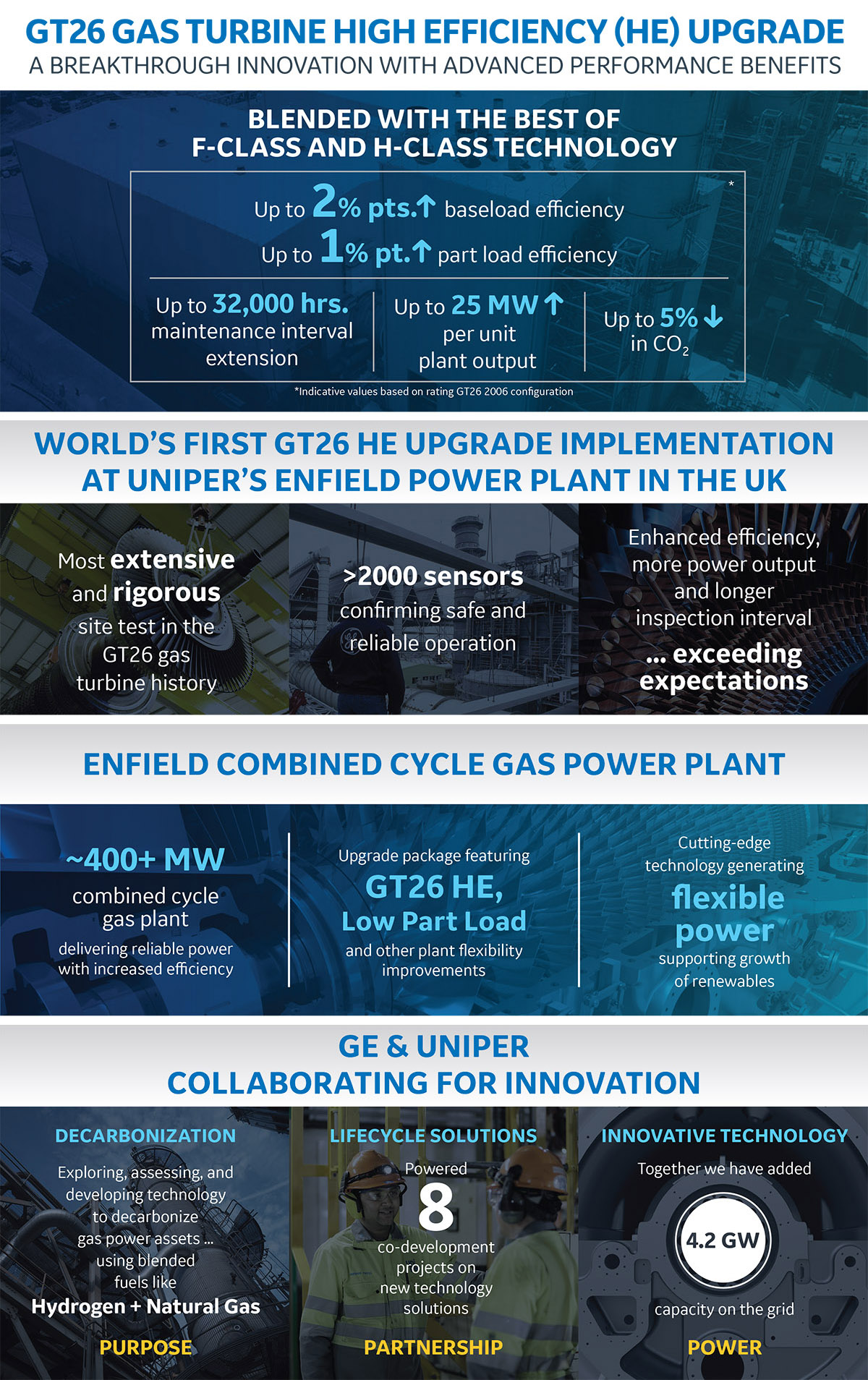

As trusted partners for over 35 years in the gas technology industry, Uniper was the perfect fit to receive GE’s GT26 HE upgrade.

The challenge

After nearly 20 years of operation, Uniper’s Enfield power plant needed a solution that could increase life-cycle value and utilization of the power generating equipment, while moving towards decarbonizing the gas power plant by reducing CO2 emissions per MW.

The solution

As a result, the GT26 HE upgrade will enable reliable operations at Uniper’s Enfield power plant to generate more energy per unit fuel with lower carbon emissions. It will also improve the plant’s performance by increasing its flexibility, efficiency and output and extend the inspection intervals of the unit.

Outcomes

Collaborating for the life-cycle

- For decades, GE and Uniper have worked together to build and maintain power plants, using leading technologies.

- Installed with HE upgrade, the GT26 unit at Uniper’s Enfield power plant is the world’s first to achieve H-class performance levels approaching 60% combined-cycle efficiency.

- During the first HE upgrade installation at Enfield CCGT, GE implemented thorough testing and validation protocols through a rigorous on-site validation campaign.

- Over 2000 sensors provided data to GE’s engineering team to confirm safe and reliable operations.

- It is among the most extensive and rigorous site tests in the GT26 gas turbine history of more than 20 years.

- GE’s GT26 HE upgrade delivers a breakthrough technology step, an innovation comparable to the first introduction of GT26 gas turbine in 1998.

Read our infographic to know more on the advanced performance benefits of the HE upgrade that blends the bests of F-class and H-class technology.