Overview

Providing the world’s first 6B repowering solution for a chemical facility in Asia

The challenge

In an industry characterized by constant change and technological advances, an industrial chemical facility in Asia needed to find a way to improve production levels.

The solution

To increase efficiency and output while reducing emissions, GE’s new 6B repowering technology will be utilized on three 6B units. The output increase of 25% is expected to help the customer accelerate the rate of chemical production and could lead to significant fuel savings.

Outcomes

Increasing output while reducing emissions

output increase

$3.5 million

potential annual fuel savings

As low as 15 ppm

NOx emissions reduction

32,000 hours

maintenance intervals extended from 24,000 hours

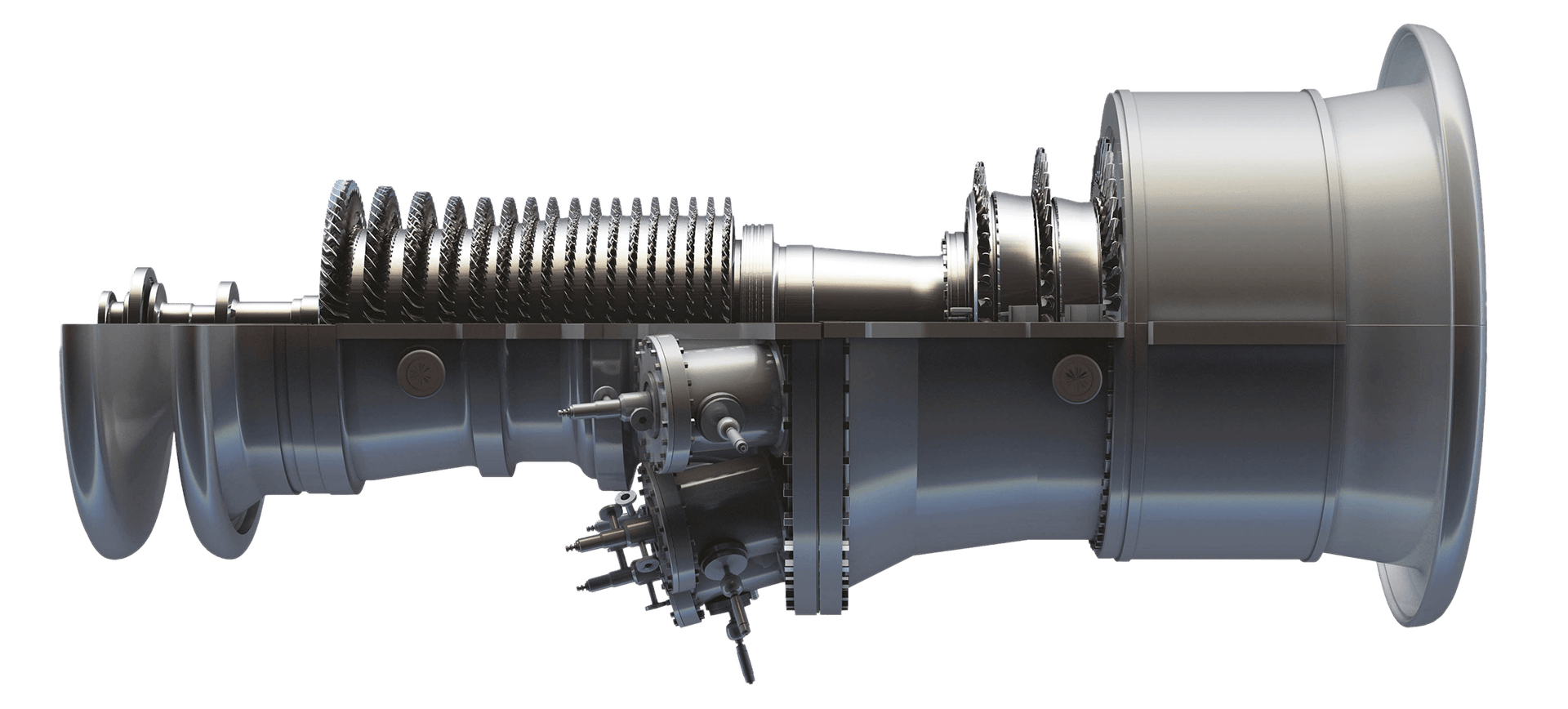

GE’s services business celebrated the 40th anniversary of its 6B gas turbine fleet in 2018 by launching the world’s first GE 6B Repowering solution. This technology was christened on three 6B units at a chemical production facility in Asia.

Part of GE’s Fleet360* platform of total plant service solutions, the newest 6B upgrade incorporates advanced F- and H-class technologies that help elevate performance to industry-leading levels for its class. It significantly increases both output and efficiency, while taking advantage of the machine’s existing footprint for short-cycle installation (70 days) compared to a new unit replacement. The leap in performance—including an output increase of 25%—is expected to help the customer accelerate its chemical production capabilities, while also realizing considerable fuel savings, thanks to more efficient operation.

The repowering solution consists of a full “flange-to-flange” upgrade of all major components, including the combustion system, hot gas path and compressor, and transforms the 6B unit into a GE 6F.01 gas turbine, which is also available as a new unit.

The upgrade can deliver:

- Output increase of 25% (simple-cycle)/35% (combined-cycle)

- NOx emissions reduction as low as 15 ppm

- Efficiency improvement up to 5 points–translating to as much as~$3.5 million in fuel a year for each 6B unit

- Extended maintenance intervals to 32,000 hours (from 24,000 hours) and major inspection intervals to 64,000 hours (from 48,000 hours)

Since its first installation in 1978, GE’s 6B fleet has accumulated more than 65 million operating hours. GE’s fleet spans more than 1,150 6B turbines across all corners of the world, powering energy production facilities and industrial applications in segments such as petrochemical, oil and gas, exploration and the cement production. Today, over 900 6Bs are still in operation with 55% in continuous operation.