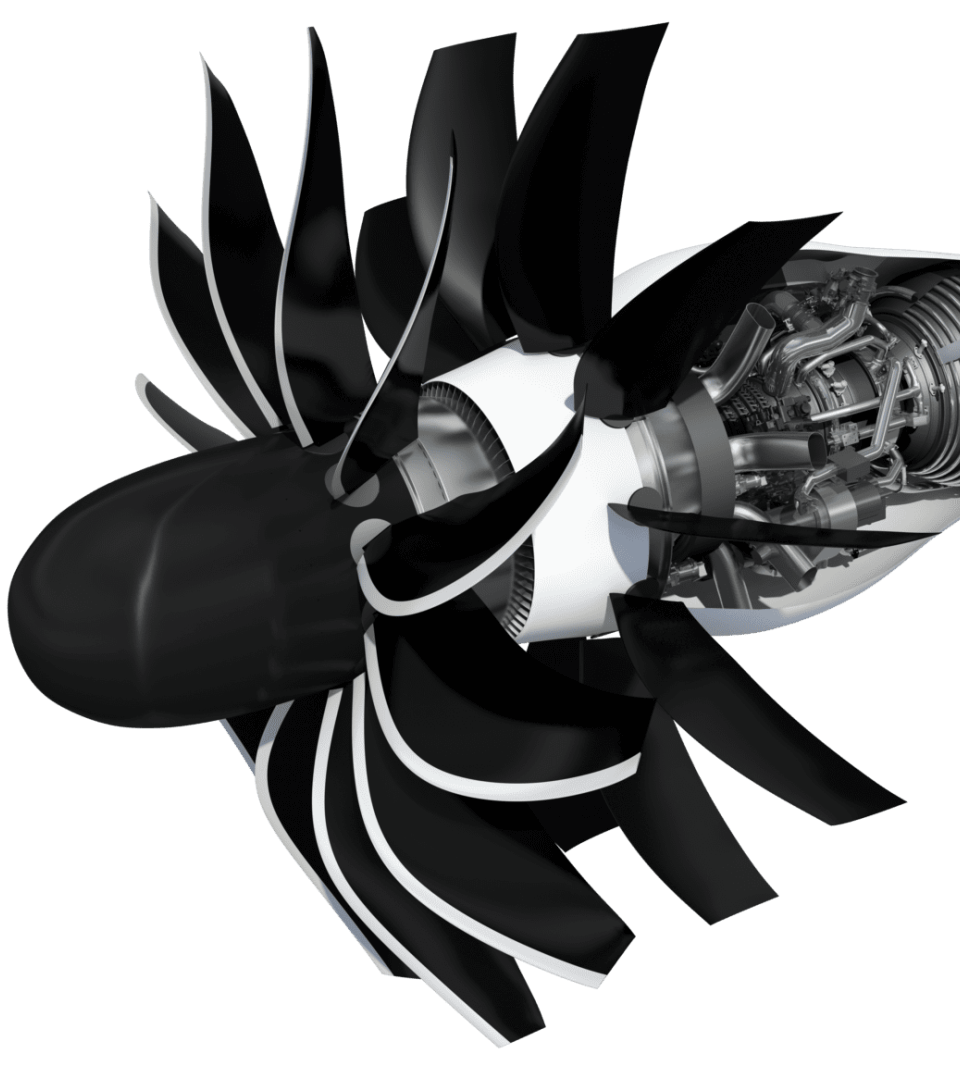

- Awarded >$4.1 million in Phase 2 funding through ARPA-E’s Aviation-class Synergistically Cooled Electric-motors with iNtegrated Drives (ASCEND) program to build and demonstrate a 350kW powertrain system

- New funding follows the successful demonstration of key technologies and the design of a 2MW powertrain system in Phase 1. This represents a key step toward a full-scale 2MW system suitable for powering future commercial aircraft

- GE’s Electric Flightworthy Lightweight Integrated Thermally Enhanced Powertrain System (eFLITES

business unit

tags

GE Aerospace and other manufacturers have been working for years to find ways to help decarbonize the airline industry. It’s quite a challenge, of course. Jet fuel produces carbon emissions, yet it’s a powerful form of energy that has dominated aviation since the Wright brothers went airborne in 1903.

New technologies, from advanced propellers and flight management systems to software focused on optimizing routes to reduce fuel use, are changing the way we fly.

Electric cars have become common, but building a commercial electric plane is a different story. Just ask Mohamed Ali, vice president for engineering at GE Aerospace. “Electric motors behave very differently at altitudes above 10,000 feet,” he says. “They are susceptible to plasma arcing, for example, and much more difficult to manage.”

With the summer holiday season underway, air travel has bounced back from its lockdown doldrums. But so has the awareness of commercial aviation’s impact on the climate.

Airlines and aircraft and engine manufacturers want to be part of the conversation.

Aviation accounts for about 2.5% of global carbon emissions. That’s why GE Aviation, CFM International — a 50/50 joint company between GE and Safran Aircraft Engines — and their airline industry and government partners are working hard to come up with solutions to reduce flight’s carbon footprint. As GE unveils its 2021 Sustainability Report, we looked back at some of this year’s biggest developments, which include sustainable aviation fuel, software that improves efficiency, hybrid electric propulsion, hydrogen fuel and other technologies.

Countries and companies have been looking for ways to cut carbon, and the aviation industry, which contributes about 2% of global carbon emissions, is no different. In 2021, the Air Transport Action Group, whose members include GE Aviation, declared the aviation industry’s commitment to a goal of net-zero carbon emissions by 2050.

One summer as a teenager, Christine Andrews visited NASA Mission Control Center in Houston with her family. Marveling at the spacecraft on display, she contemplated the thrill of contributing to space discovery. It wasn’t a stretch. She was already participating in high school symposiums for women in math and science. Yet the idea was daunting. “You look at all the buttons in the capsules and think, Who knows what all of these do, let alone how they all work beneath that?” she recalls.

Speaking at the Techonomy Climate 2022 conference in Mountain View, California, on Tuesday, Roger Martella, GE’s chief sustainability officer, wanted to quickly underscore what brought him there: “I think history will look back on this day, this month, this year, and say this was the era of climate innovation,” he said.

Last October, NASA and GE Aviation announced a new partnership to mature a megawatt-class hybrid electric engine that could power a single-aisle aircraft. Today the project got one step closer to takeoff. GE Aviation has selected Boeing to modify the plane that will test the propulsion system in the air.