But the real world is still pretty messy. GE’s 500-plus factories and manufacturing sites, for example, hold billions of dollars’ worth of inventory. Those compressors, propellers, fuses, resistors and other parts take up space in warehouses that must be kept staffed, lit and maintained. All that money could be put to work more productively somewhere else.

It’s exciting for us at GE Digital to see our investments pay off. But we also should pause to take stock of our progress and refocus on what remains to be done.

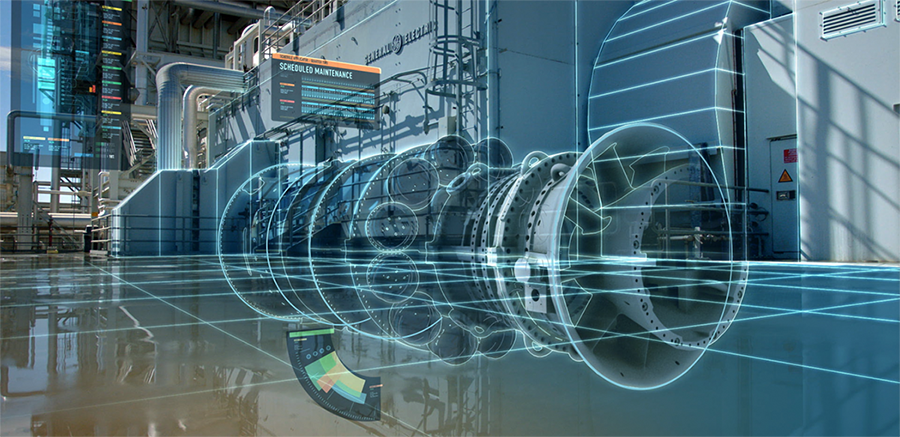

GE is changing the conversations with Industrial Internet. GE is connecting a network of intelligent machines which will transform businesses as dramatically as the consumer Internet has changed our lives. GE is bringing together industrial engineering with sensors, software and big data analytics to create brilliant machines.

The introduction of big data analytics has helped the industry improve on its efficiencies, facilitating industry players to reduce downtime and optimise resources. General Electric (GE), for example, has presented various digital industrial solutions.