There are skilled engineers, and there are able business leaders. Walter Robb was the rare mixture of both.

A month ago, Jussi Määttä didn’t think he would be part of the fight against COVID-19, the disease caused by the novel coronavirus. His Helsinki-based company, Buddy Healthcare, makes an app that helps hospitals ensure that patients are taking the necessary steps — like fasting, avoiding blood thinners and doing stretching — before and after surgery.

Sporting and political pundits often argue that attack is the best form of defense but when it comes to the new coronavirus and COVID-19, the disease it causes, the opposite may be true, at least for now. The healthcare workers who are fighting a 24/7 battle against the pandemic desperately need personal protective equipment (PPE) such as gowns, gloves, goggles and masks to shield themselves against the germ.

Millions of Americans have been told by state officials to stay home to help slow the spread of the coronavirus. But working from home isn’t an option for everyone, and some operations deemed essential and allowed to stay open can’t slow down or stop, even temporarily: Utilities have to keep the lights on and the water running, for instance.

Mechanical ventilators, machines that keep people breathing when their lungs are seriously compromised, are all over the news lately. They’re an important tool for doctors and nurses working to help the sickest patients suffering from COVID-19, the disease caused by the novel coronavirus. And right now, hospitals around the world need more of them.

This week in the fight against COVID-19, researchers tested a common technique to decontaminate much-needed face masks, made strides on a possible vaccine, and looked to a pandemic of the past to learn valuable economic lessons.

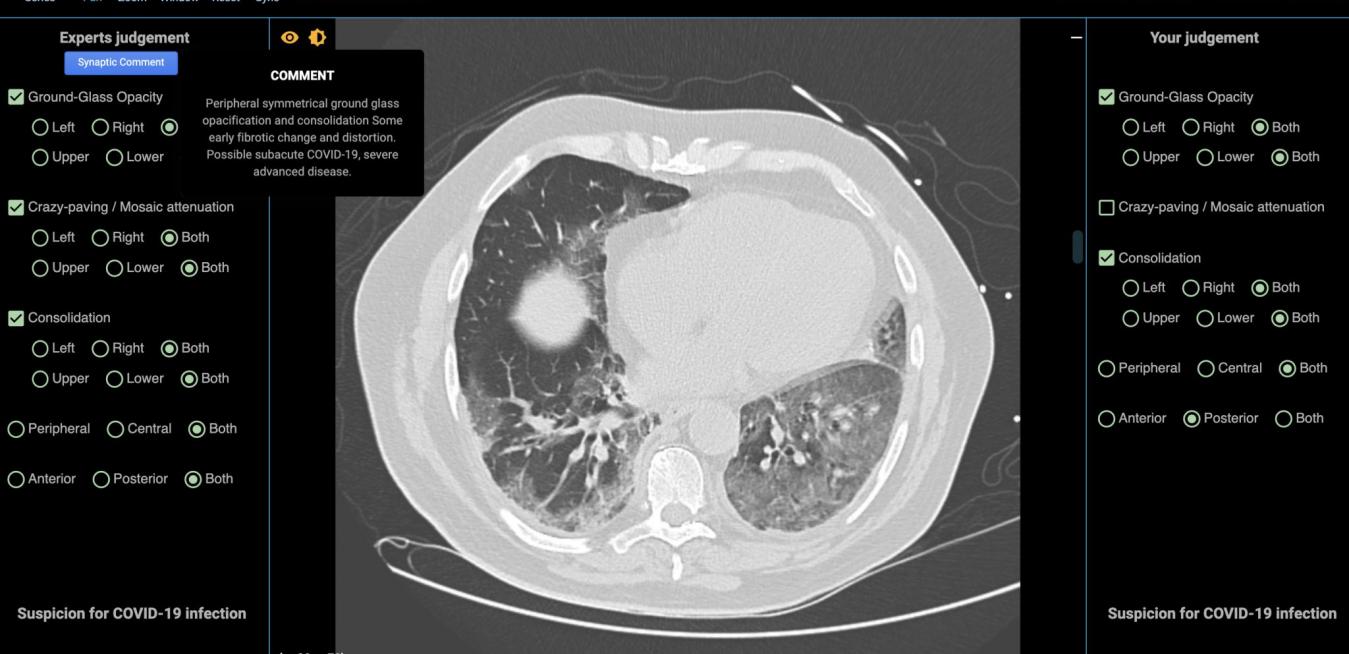

CT scans are one of the most valuable tools to rapidly and accurately diagnose COVID-19 infection and help triage patients for treatment. But because the virus is new, few specialist radiologists have experience in identifying early signs of COVID-19 on CT scans. Equally important as the pandemic escalates globally, a wider set of medical professionals may be called on to interpret CT scans.

When Jimmie Beacham’s grandfather was a small boy growing up near Kitty Hawk, North Carolina, he observed the Wright brothers’ early attempts at flight. Flash forward over a century later, the younger Beacham is watching history unfold in a different way. While the world scrambles for ventilators needed to fight the COVID-19 pandemic, Beacham is helping plant leaders add ventilator production lines at GE Healthcare’s factory in Madison, Wisconsin. He’s also looking at using manufacturing technologies like 3D printing to boost output.

As COVID-19, the disease caused by the new coronavirus, started cropping up across the United States in March, Caroline Shaw knew the pandemic would alter many parts of her job as a sourcing manager at GE Renewable Energy’s wind turbine factory in Pensacola, Florida. What Shaw hadn’t expected was for the virus to present her with a problem that seemed to have no simple solution.

Tyler Vermey knew something was happening when his boss called on a Sunday. The engineer, who was relaxing at home in Salt Lake City with his wife, Krista, and their beloved springer spaniel, Bruno, doesn’t get many weekend calls from his manager. “I was caught a little off-guard,” he admits. But his boss had an urgent message: Vermey was needed at GE Healthcare’s manufacturing plant in Madison, Wisconsin — pretty much immediately.