Anyone who’s met her will tell you that Harriet is not like other house guests.

When she arrived from France in Greenville, SC, earlier this year, her hosts at a local GE gas turbine factory had to build a new train turntable just to get her settled in her quarters. They also erected a gas plant to keep her fed.

That’s because Harriet, whose real name is the 9HA, is the largest and most efficient gas turbine in the world.

When GE engineers wanted to make their jet engines more efficient, they developed a special ceramic material that can operate at temperatures where most metal alloys grow soft. But the idea of putting ceramics inside jet engines was so revolutionary that they took the material to a shooting range and blasted it with steel balls flying at 150 mph to prove that it was viable (see image below).

People have been using ceramics to store food, drink tea, and tile their homes for millennia. But GE engineers recently upped the ante and started putting high-grade ceramics inside jet engines.

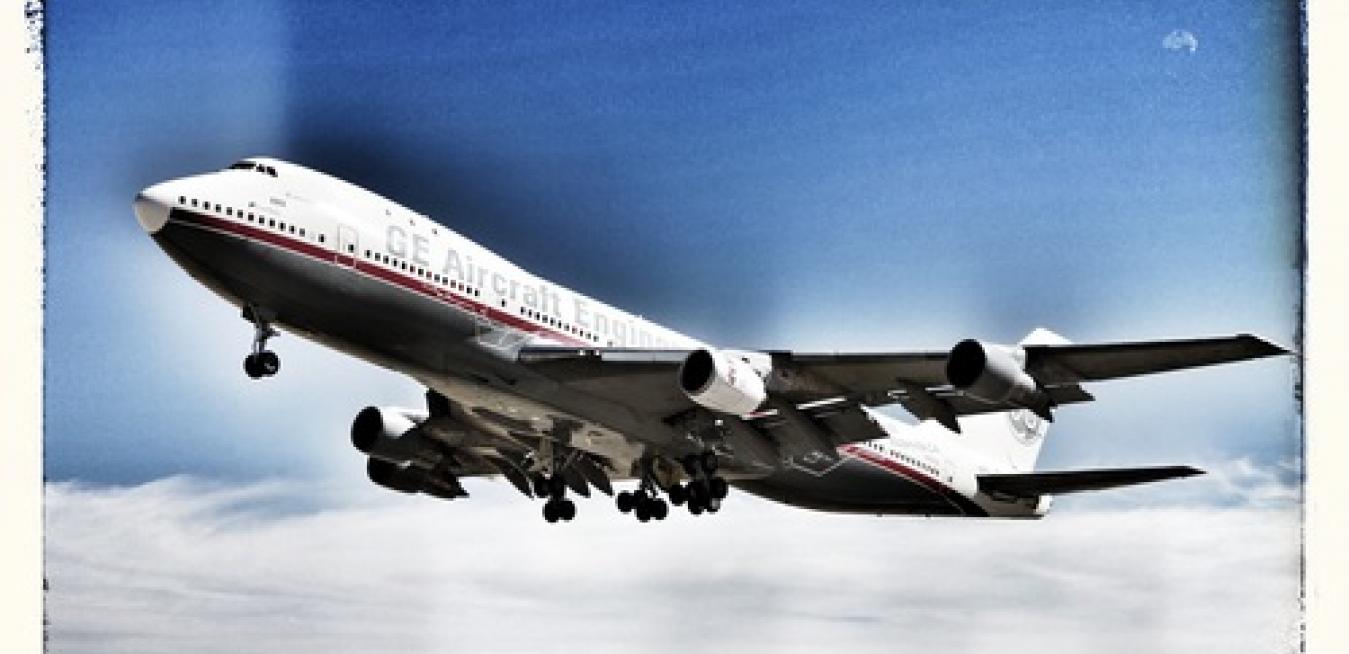

David Joyce, president and CEO of GE Aviation, spent the last decade developing some of the world’s most advanced jet engines. His timing was perfect. Plane manufacturers estimate that the world aircraft fleet will double in size over the next 20 years to some 40,000 planes. Joyce now needs to make enough engines to meet the voracious demand.