Dan Morey had a problem. He knew the vast compressed air system in Building 273 was leaking air, but he didn’t know where.

Workers at GE Aviation’s Lafayette, Indiana, jet engine-manufacturing plant were facing a problem. They had to hand-start 48 nuts in a tedious process that forced technicians to use repetitive wrist and hand movements.

In the 1970s, a team of researchers from the Massachusetts Institute of Technology traveled to Japan to figure out why that country’s automakers were delivering cars faster than their competitors in Detroit. Their search led them to Toyota and its Toyota Production System — a set of management principles focused on boosting safety, quality and efficiency, reducing waste and creating more value with fewer resources.

Categories

L.R. Phanindra is a strong believer in working smarter. The environmental health and safety (EHS) manager has spent nearly two decades improving production lines, including at the Wipro GE Imaging plant in Bengaluru, India, which manufactures CT machines, MR scanners and other GE Healthcare technology.

Workers at GE Renewable Energy’s plant in Pensacola, Florida, have a reason to feel good about their work. They make some of the most popular onshore wind turbines on the planet. The GE unit’s 2-megawatt (MW) onshore wind turbines reached a mind-blowing milestone in 2020 — a combined 20 gigawatts of installed capacity in 23 U.S. states and 10 countries. That’s enough to power the equivalent of 12.9 million homes around the world.

The 1980s are back in fashion, according to Harper’s Bazaar, but in some corners of industry, they never left. “Nobody’s wearing big hair and shoulder pads, but it’s all very pencil and paper,” says Jeremiah Smedra, an operations director at FieldCore, GE’s field services company. Smedra is talking about maintenance workers trudging into power plants with thick binders filled with drawings and instructions to make sure outages are performed according to plan.

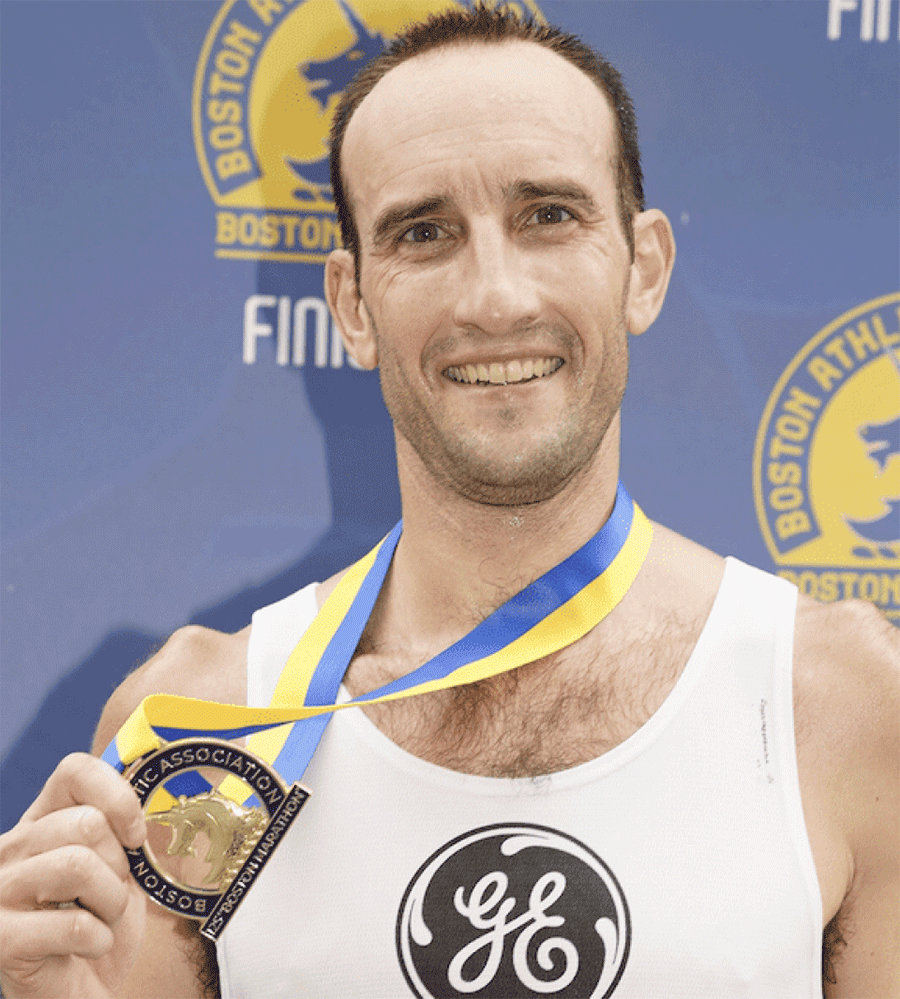

Engineer and avid runner David Riddle usually finds himself asking “Why do I do this” during races. But this year’s 125th running of the Boston Marathon was an exception.

That’s not to say that it wasn’t hard or that it didn’t hurt. It did. But everything was going according to plan. A rarity in distance running. While Riddle has run upwards of 10 marathons, many more 50K+ races and even two 100-plus-mile races, this was his first Boston Marathon.

In the 1970s, a team of researchers from the Massachusetts Institute of Technology traveled to Japan to figure out why that country’s automakers were delivering cars faster than their competitors in Detroit. Their search led them to Toyota and its Toyota Production System — a set of management principles focused on boosting safety, quality and efficiency, reducing waste and creating more value with fewer resources.

Back in 2017, GE engineers surprised the world when they took what was then the world’s most powerful jet engine and used its technology to turn it into a power plant that could be capable of generating enough electricity for thousands of households. This feat got plenty of attention, but the team was not finished. A new GE team has now turned the machine into yet another example of the power of innovation.

Ezra Laurent is a mechanical engineer, but he likes to think like a sports coach. “I’m always asking questions,” he says. “What can we do better? How can we change things? Who are our best performers? What can we do differently?” But Laurent isn’t seeking to get an edge from elite athletes. He and his team are working to get the very best out of another group of powerful performers: a fleet of GE’s gas turbines that generate electricity for people around the world.