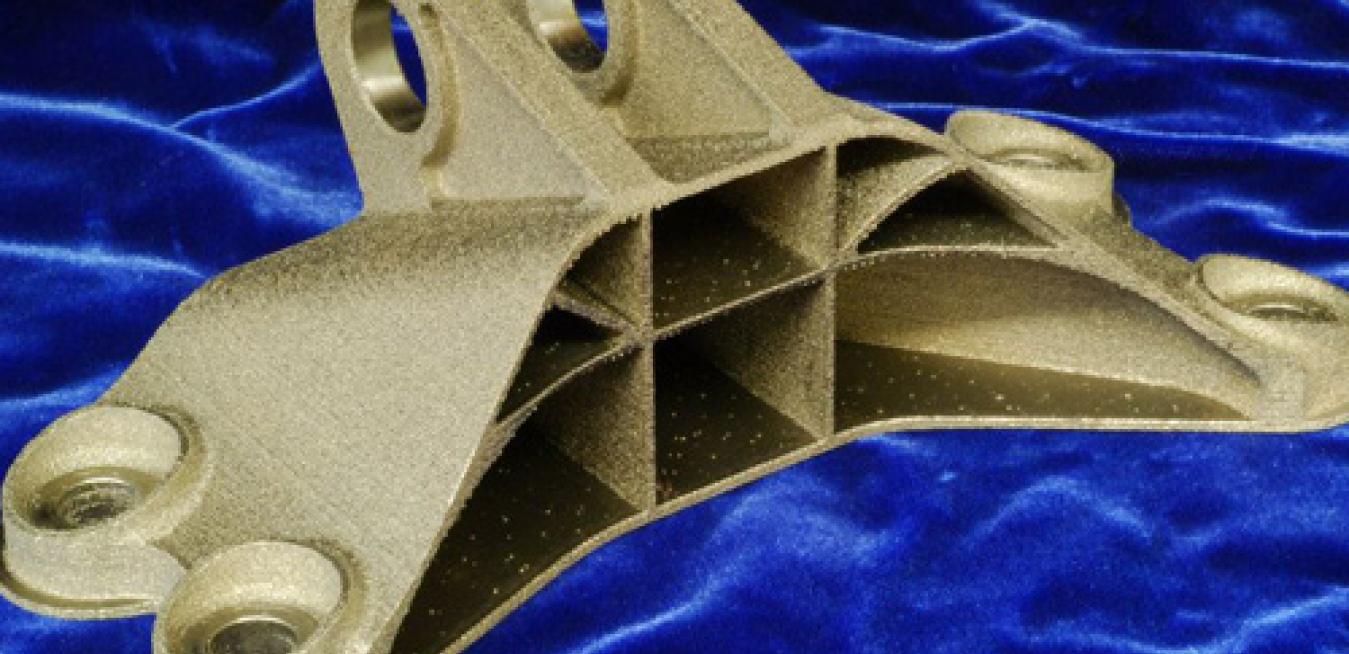

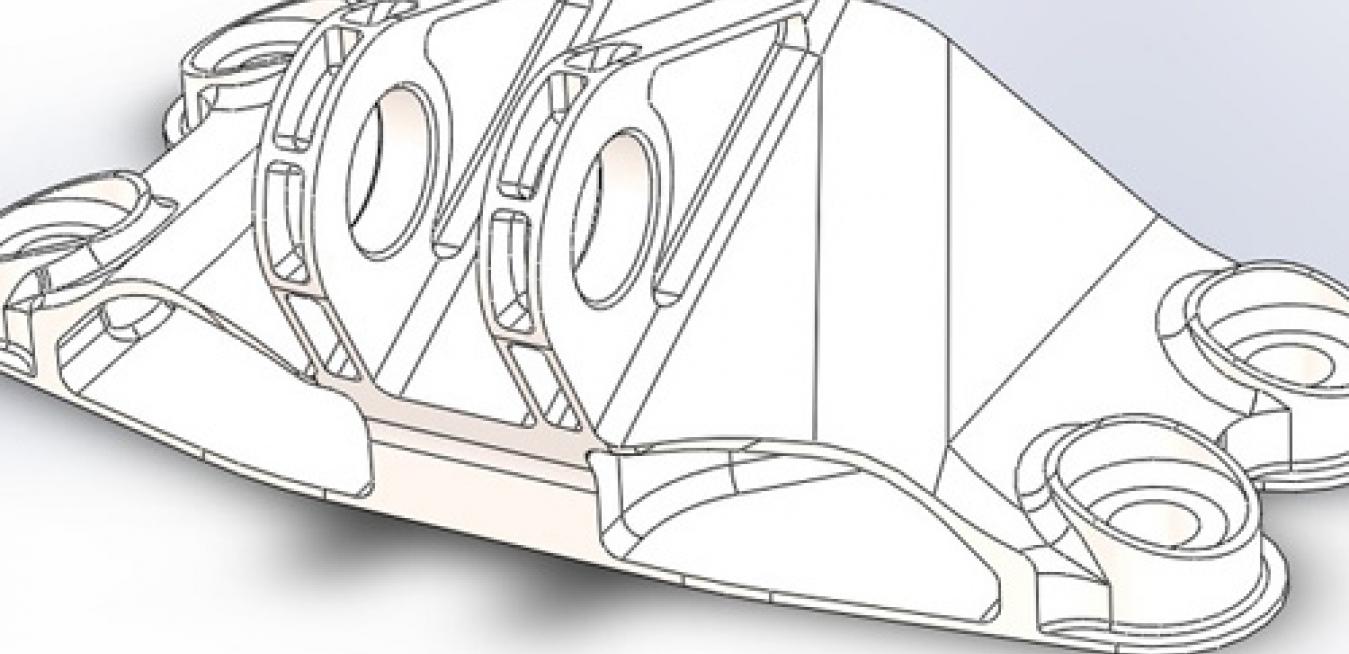

Freed from the boundaries of traditional materials, additive manufacturing allows engineers to design more organically, optimizing weight-to-strength ratios with design flexibility. The process also has the benefits of using less material and producing less waste.

In Ancient Egypt there exists evidence of the basic design process of defining objectives, performing research, specifying requirements, iterating while developing solutions, and prototyping before building the final version. The same process is followed today.

But the cool factor of 3D printing sometimes obscures a movement in manufacturing that could have an even bigger impact: platforms that help us share ideas, suppliers and marketplaces. That emerging network is why I’m optimistic that 2014 marks the rise of the hardware startup.

A jet engine bracket designed by M Arie Kurniawan, an engineer from Salatiga in Central Java, Indonesia, came in first place in a global 3D printing challenge held by GE and the open engineering community GrabCAD. Kurniawan will receive $7,000 in prize money. GE and GrabCAD also selected seven other design winners who will divide the balance of the $20,000 prize pool.