It’s been a week splashed with sunshine at the Farnborough International Airshow — an unusual sight for England in July — but GE Aviation still made it rain. The GE unit that makes aircraft engines, plane components, avionics and other aerospace technology said it and its partner, CFM International, have won orders valued at more than $22 billion at list price.

The award for the most jaw-dropping display at the 2018 Farnborough International Airshow goes to the Russian cargo airline Volga-Dnepr.

We mean it literally.

Sign up for a new bank account or buy a new car and chances are you’ll be prompted to download corresponding apps that will give you the ability to control your finances or your car stereo from your phone. Constantly updating your phone in this way — so it’s customized to your life — is so routine at this point that most of us just take it for granted.

You probably wouldn’t print a letter without carefully composing and editing it on a computer screen first. So it’s fitting that as companies embrace 3D printing, their workers are spending a lot of time on their computers making sure the parts they want to print come out right. And just like writers need a good word processor to keep track of their changes, industrial designers need sophisticated software to run simulations as they perfect their parts.

As the executive leader for robotics at GE Global Research, John Lizzi may have one of the coolest jobs at GE. His desk is right next to a classroom-size lab filled with collaborative robots that can safely work next to humans; envelope-like devices that can worm inside a jet engine, inspect it and even fix it; and drones that can keep an eye on wind turbines and other large industrial assets. GE Reports recently visited Lizzi’s lab and talked to him about his favorite robots and the latest developments in the field.

GE announced major changes to its business portfolio today designed to stimulate growth and generate more value for shareholders. GE’s Aviation, Power and Renewable Energy units will form a new core of the company. GE plans to turn GE Healthcare into a standalone business, distributing 80 percent to GE shareholders and monetizing the remaining 20 percent.

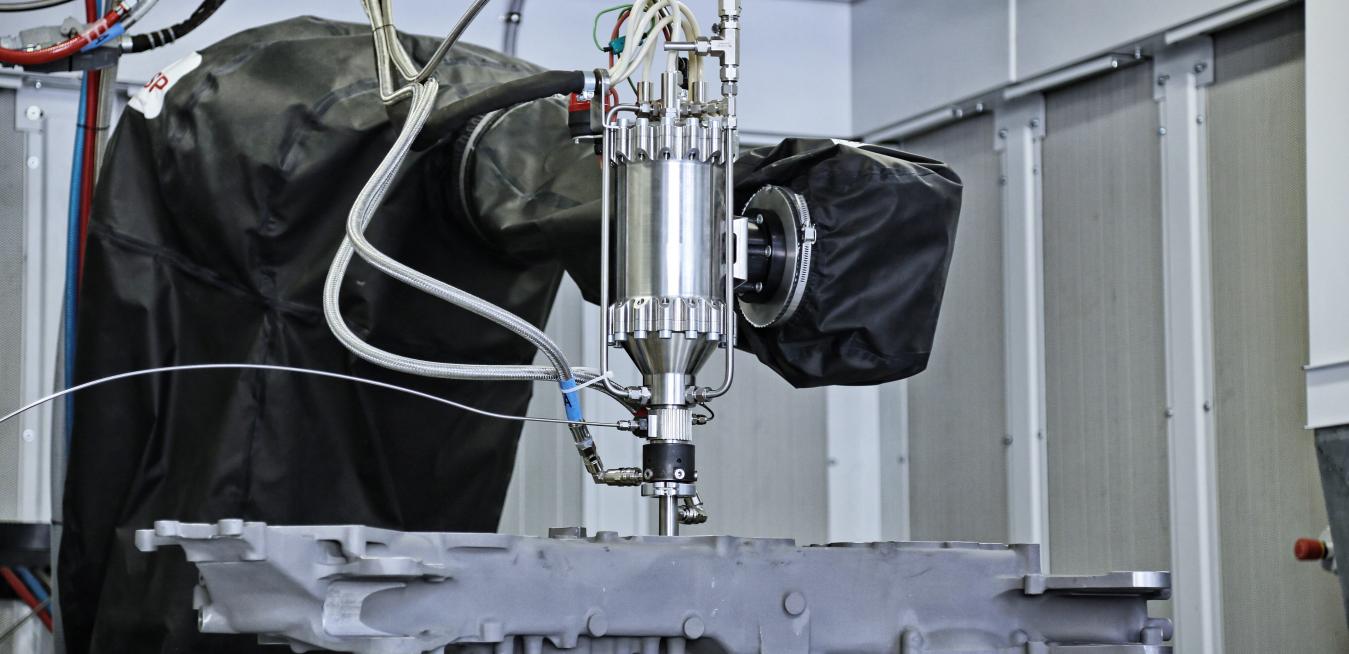

Few places illustrate the rapid evolution of 3D printing better than Avio Aero’s gleaming box of a factory in Cameri, a small town near Milan in northern Italy. The plant is filled with 20 sleek, black 3D printers, each the size of an armoire.

As a frequent flyer throughout APAC, I've witnessed - usually from a window or aisle seat - the incredible growth of the regional aviation market sector since the early 2000s.