A review of the impact of U.S. trade deals since NAFTA shows they have improved U.S. trade balances and boosted exports, getting U.S.-made goods on the shelves of its trading partners.

A key demographic could help close the skills gap in manufacturing: women. We need to do a better job of attracting and retaining this untapped resource.

U.S. manufacturers today face a tremendous challenge finding quality talent to stay competitive in the global economy. Over the next decade, nearly 3.5 million manufacturing jobs likely will need to be filled, and the skills gap is expected to result in 2 million of those jobs going unfilled.

By embracing “bottom-up” innovation, the U.S. government can help advanced manufacturing respond to the speed and complexity of technological change.

Gaining a national edge in the advanced manufacturing space typically isn’t a “top down” process, especially given the speed of technological change. Given that, one of the great strengths of the Obama administration’s National Network for Manufacturing Institutes (NNMI) initiative has been its vision of competitive, “bottom up” project selection and governance.

This bipartisan effort gaining momentum in Congress will ensure manufacturing’s renaissance.

Americans have come a long way from the depths of the Great Recession. Our businesses have created 12.1 million jobs over the past 61 months, the longest sustained stretch of job creation in our nation’s history, and a key driver of that economic recovery has been a sector that helped build this country’s middle class — manufacturing.

Manufacturing is revitalizing our economy and making America strong. Investments in manufacturing multiply across the economy, creating jobs and growth in other sectors. Every dollar in final sales of manufactured products supports $1.32 in output from other sectors — the largest multiplier of any sector. Manufacturing employs more than 12 million people with innovative and rewarding jobs that include salaries and benefits well above the national average.

We need more women in leadership positions in manufacturing. MaryAnn Wright, the top engineer at Johnson Controls, draws lessons from her own experience.

I traded in my business suits for steel-toed shoes and safety glasses. The goal? As Ford’s first female plant engineering manager, I led the team responsible for launching almost $1 billion in vehicle updates to the company’s flagship Taurus and Sable product lines. Every component and system — from the powertrains, structures, closures, interiors and chassis — were to be modified.

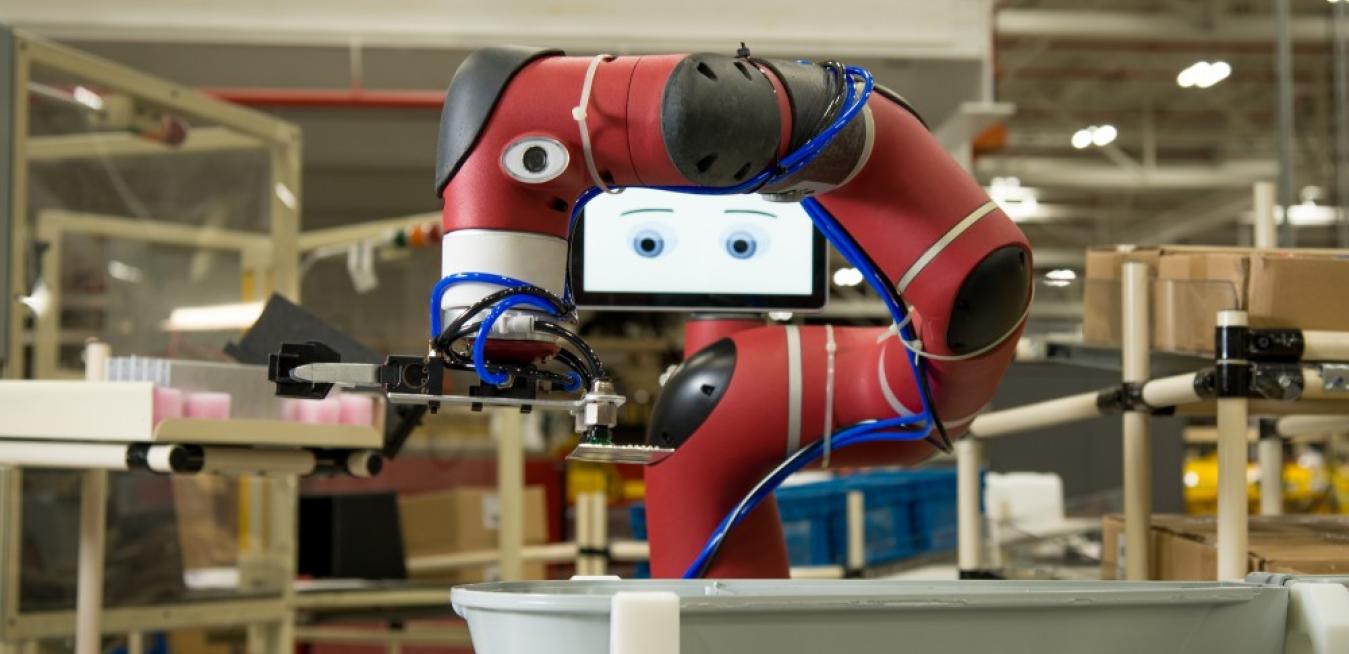

From micro-manufacturing and co-creation to the first 3D-printed car, Jay Rogers is remaking the manufacturing process.

If the democratization of manufacturing is being fueled by forces such as the open-source movement and 3D printing, Jay Rogers may be sitting in the driver’s seat.