There is more than one way to fly a plane. When the weather is good and the skies are open at the destination airport, pilots can cut costs by loading less fuel and shedding the extra weight. But they need good information to make the call.

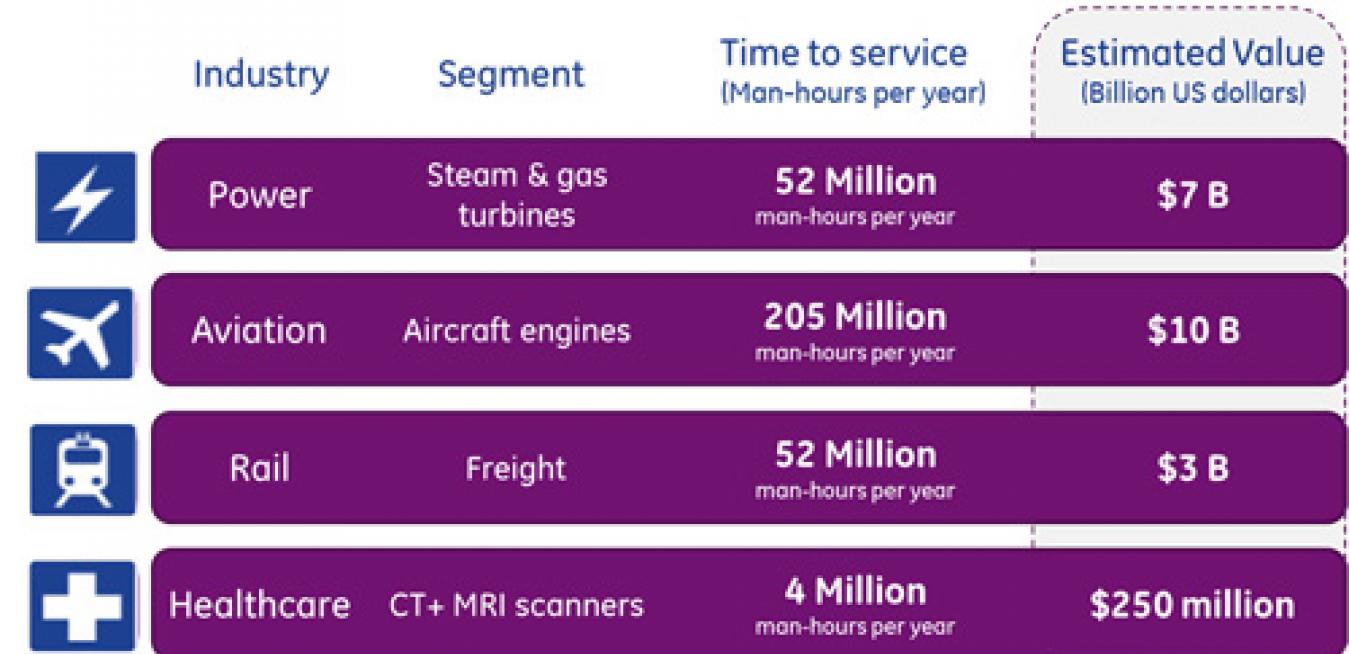

A gas turbine service manual can clock in at 1,000 pages, about the length of a small-type version of War & Peace. Crews often haul the tomes from one remote location to another to do maintenance work. They travel on a set timetable and lack real-time information about the condition of the turbines. “If they come too late and failure occurs, unplanned downtime can cascade across the system and affect the economy,” says GE Chief Economist Marco Annunziata.

Etihad Airways, the United Arab Emirates’ flag carrier, will tap the Industrial Internet and use sophisticated software to harvest and analyze gigabytes of data generated by hundreds of sensors working inside its planes. The tools will allow Etihad to monitor planes in real time, reduce fuel costs, manage plane maintenance, and even spot problems before they happen.

Utility bills, electronic airline tickets and medical records already live in massive data centers we’ve come to call “the cloud,” putting them never farther away than our fingertips. But GE said today it would start moving far more complex machine data to the cloud and build the first big data and analytic platform robust enough to manage the torrent of information generated by turbines, jet engines, medical scanners and other technology.

Nobody likes waiting and doctors at Florida’s Aventura Hospital and Medical Center hate crowded waiting rooms as much as their patients.

That’s why last year Aventura invested in AgileTrac, a GE software system that pools and crunches gigabytes of patient and equipment data zipping across a hospital-size digital network.

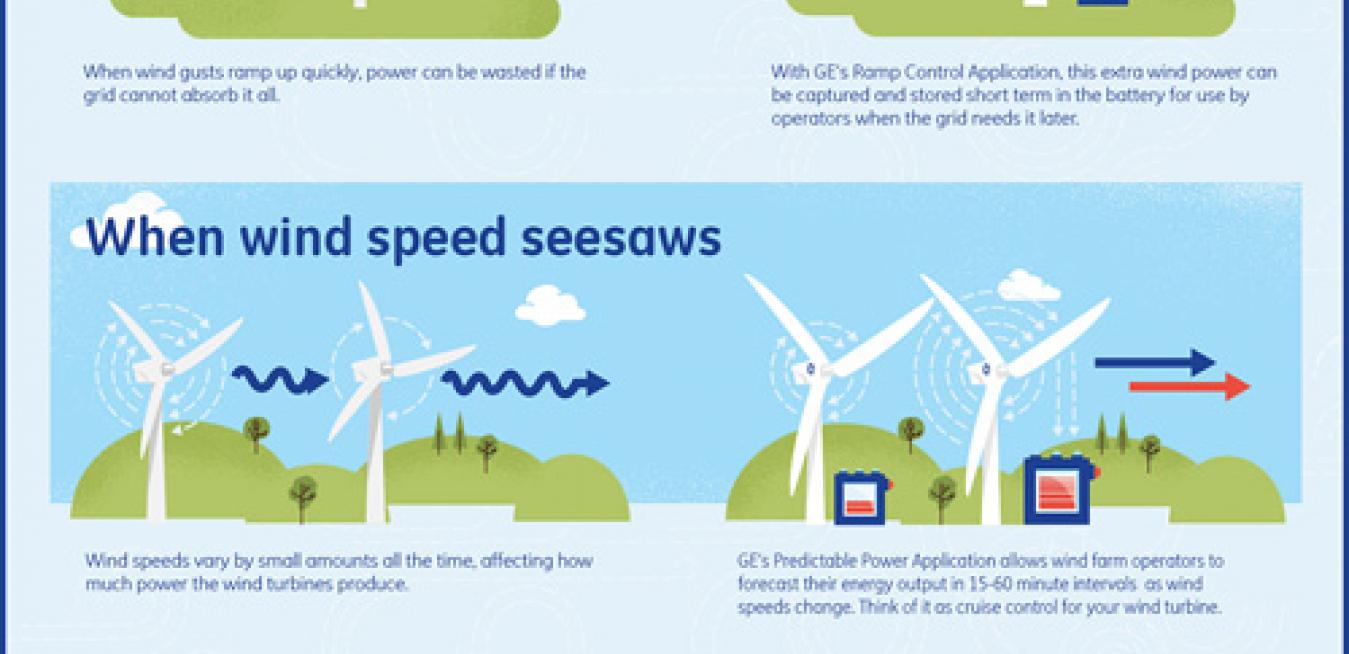

Is a blustery day a boon for a wind farm or too much of a good thing? It depends, says Keith Longtin, general manager for wind products at GE’s renewable energy business. “The grid can’t always accept wind power as fast as it comes up,” Longtin says. “When it’s gusting, turbines turn their blades out of the wind and let some of the power pass through. That revenue is gone with the wind.”

GE will invest $105 million in the cloud-based software applications company Pivotal. The strategic investment in the VMware and EMC spin-off will allow GE to speed up development of advanced analytic services for the Industrial Internet.

The apps will allow customers to analyze and understand big data generated by machines and stored in the cloud. “It’s no secret that the cloud and big data are driving dramatic business transformation,” said Bill Ruh who leads GE Global Software Center in San Ramon, California. “They are enabling the Industrial Internet.”

A new generation of jet engines, locomotives, MRIs and other big machines loaded with sensors generating gigabytes of data and linked in networks will become more efficient to operate, easier to deploy, and more accessible to innovators, according a new report on the industrial internet published by O’Reilly Media and sponsored by GE. “The barriers between software and the physical world are falling,” the report says. “It’s becoming easier to connect big machines to networks, to harvest data from them, and control them remotely.”