In an always on, always learning society, companies that embrace the Industrial Internet will be more intelligent and efficient.

The exponential growth of data from connected devices has the potential to create a society that is always on and always learning. Interconnectedness is also poised to transform entire industries, as companies harness the Industrial Internet to gain unprecedented efficiencies.

Despite the promise of the Internet of Things to redefine how we interact with the things around us, the reality may be closer to many competing Intranets of Things — each with its own network of users and products.

The digital age will provide manufacturing insights that will save money and transform how we work across supply chains.

As manufacturing leaders and innovators converge on Detroit for the annual Big M Conference, it’s clear the digital revolution in manufacturing has taken hold. Just glancing at the title of major talks and presentations in the conference program will show just how much digital has penetrated mindsets.

- “Transforming Your Manufacturing Business for the New Digital Age”

Disruptive innovation requires more than prototypes and patents. Companies need cost-effective access to the resources they need to make their concepts commercially viable.

Not too long ago, America was the world leader in pushing projects through the development pipeline, from basic R&D all the way to a finished product that could be marketed to consumers on a massive scale.

In fact, they’re increasingly essential to the competitiveness of a country’s manufacturing sector.

There is good evidence that robots are a driver of economic growth, given new research by George Graetz and Guy Michaels showing the impact of automation technology in productivity statistics. But this raises a question: Has productivity growth from robots come at the cost of manufacturing jobs?

Innovations in 3D printing, wearable technology and Big Data are enabling a greater understanding of our own biology. Yet with opportunities come new challenges.

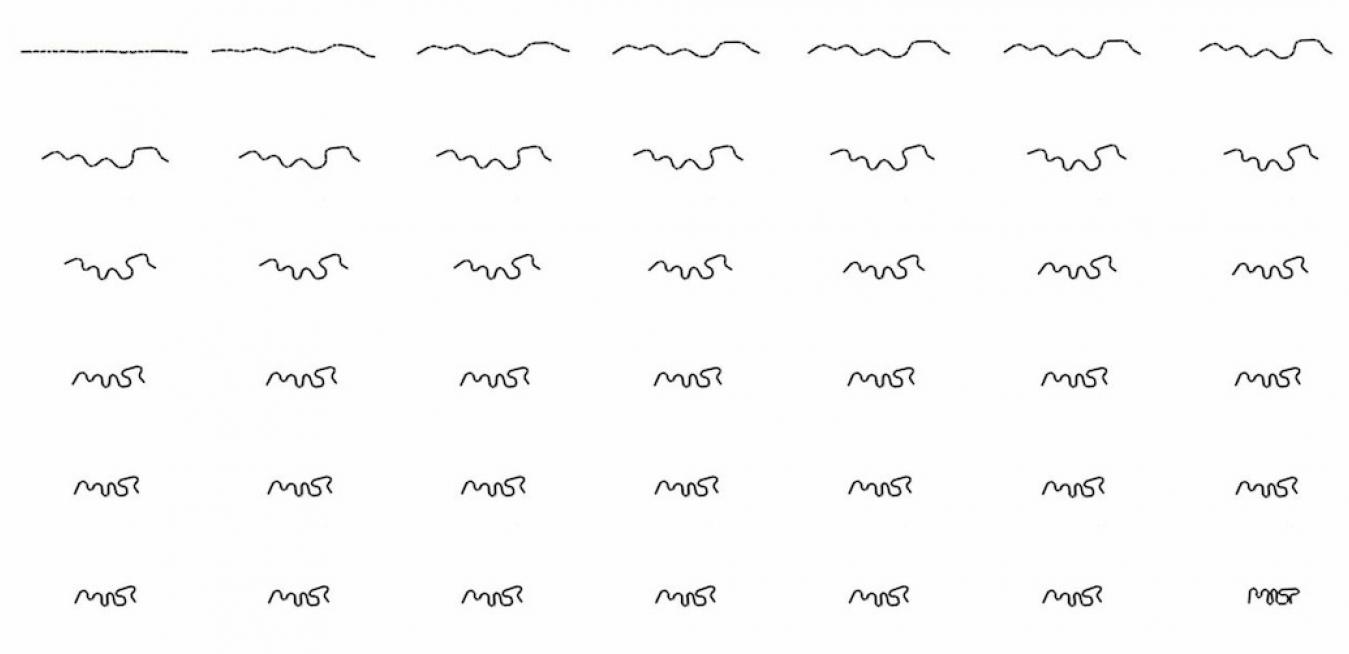

Who are we? That unresolvable question may increasingly give way to “What are we?” This is because we are fast entering a future where our biology is becoming more self-defined, assembled, manufactured and unique. Great disruptive technologies, in combination with enormous advancements in science, are shifting our understanding of our own biology. We are:

There’s no shortage of support programs for entrepreneurs. We need to make sure they’re effective in creating a global ecosystem that accelerates the next generation of scalable new business creation.

Rethink Robotics CEO Scott Eckert talks about the potential for smart, collaborative robots to solve the labor cost and labor shortage problems in manufacturing.

Humans have been fascinated with robots and automatons for millennia — or, at least, since Talos, the mythical bronze giant made by the Vulcans that guarded Crete.

This bipartisan effort gaining momentum in Congress will ensure manufacturing’s renaissance.

Americans have come a long way from the depths of the Great Recession. Our businesses have created 12.1 million jobs over the past 61 months, the longest sustained stretch of job creation in our nation’s history, and a key driver of that economic recovery has been a sector that helped build this country’s middle class — manufacturing.