Categories

tags

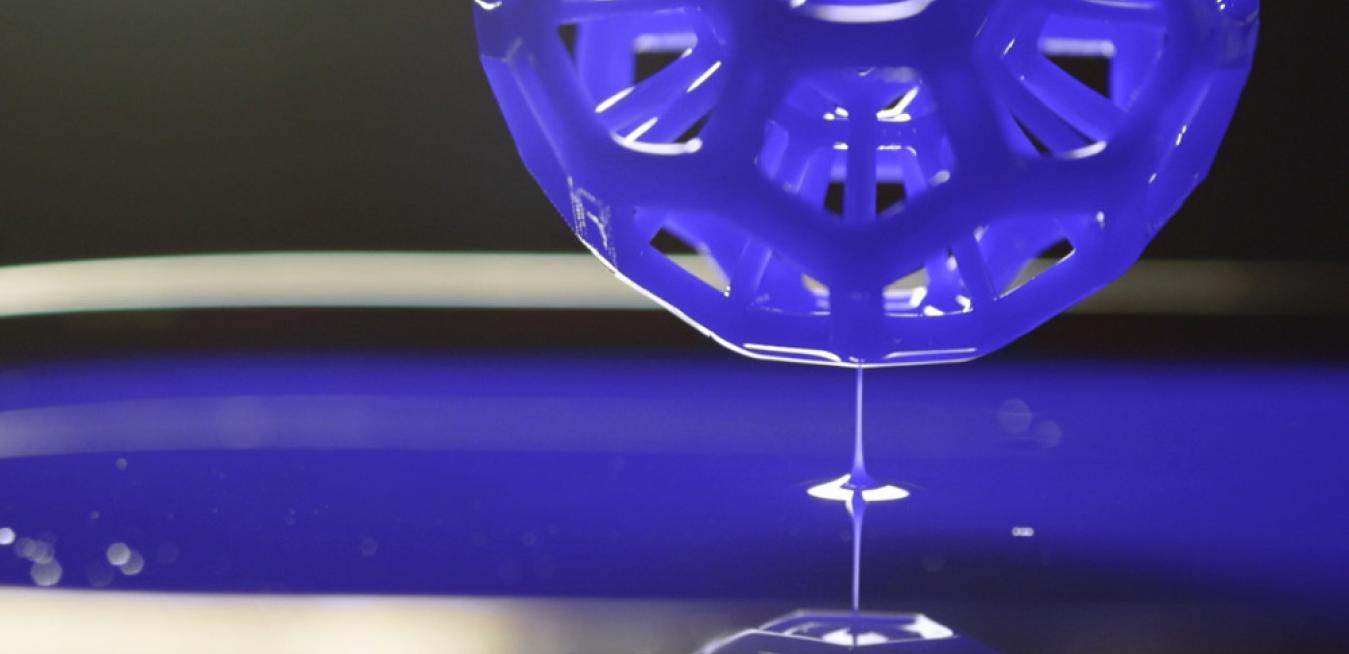

Developed by Silicon Valley startup Carbon, M1 works by plunging a flat build plate into a liquid bath of resin. An ultraviolet LED projector below then flashes a two-dimensional image—a single layer of a 3D object—through the bath’s translucent container bottom and onto the plate.

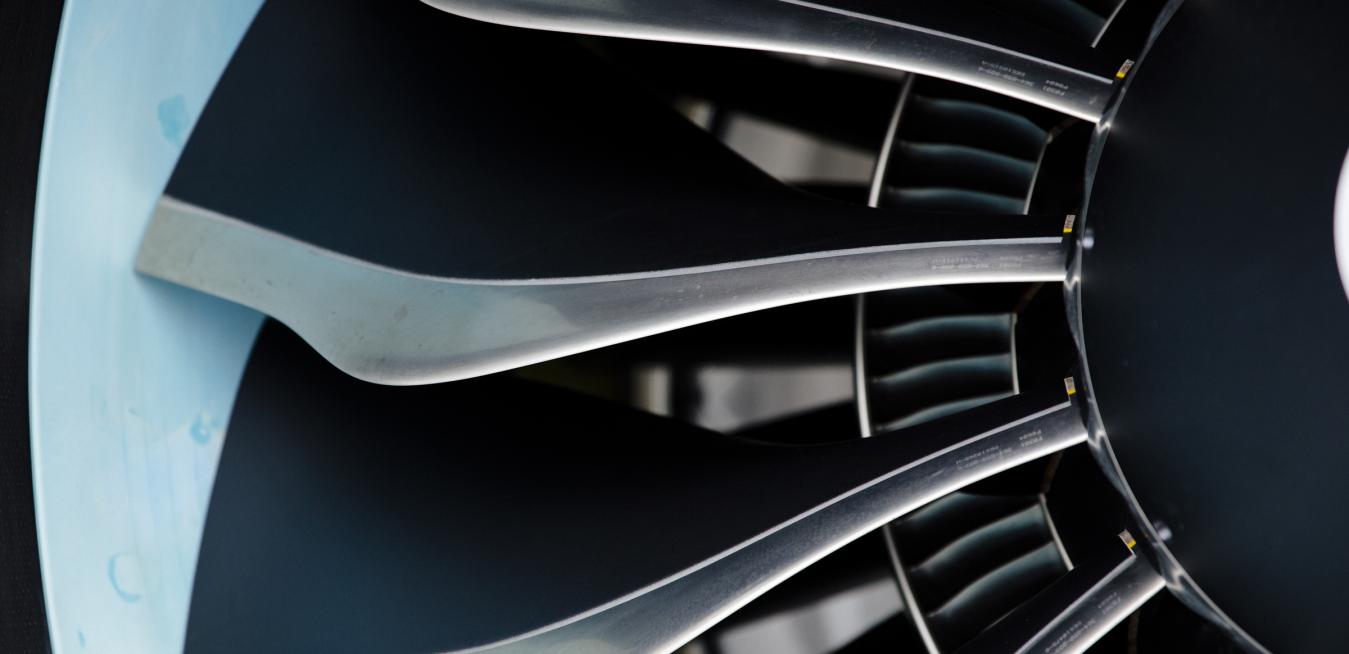

Consider it a jet engine for the Oompa-Loompas. GE engineers working on the future of aircraft manufacturing recently showed off some of their capabilities. They made a simple 3D-printed mini jet engine that roared at 33,000 rotations per minute (see video above).