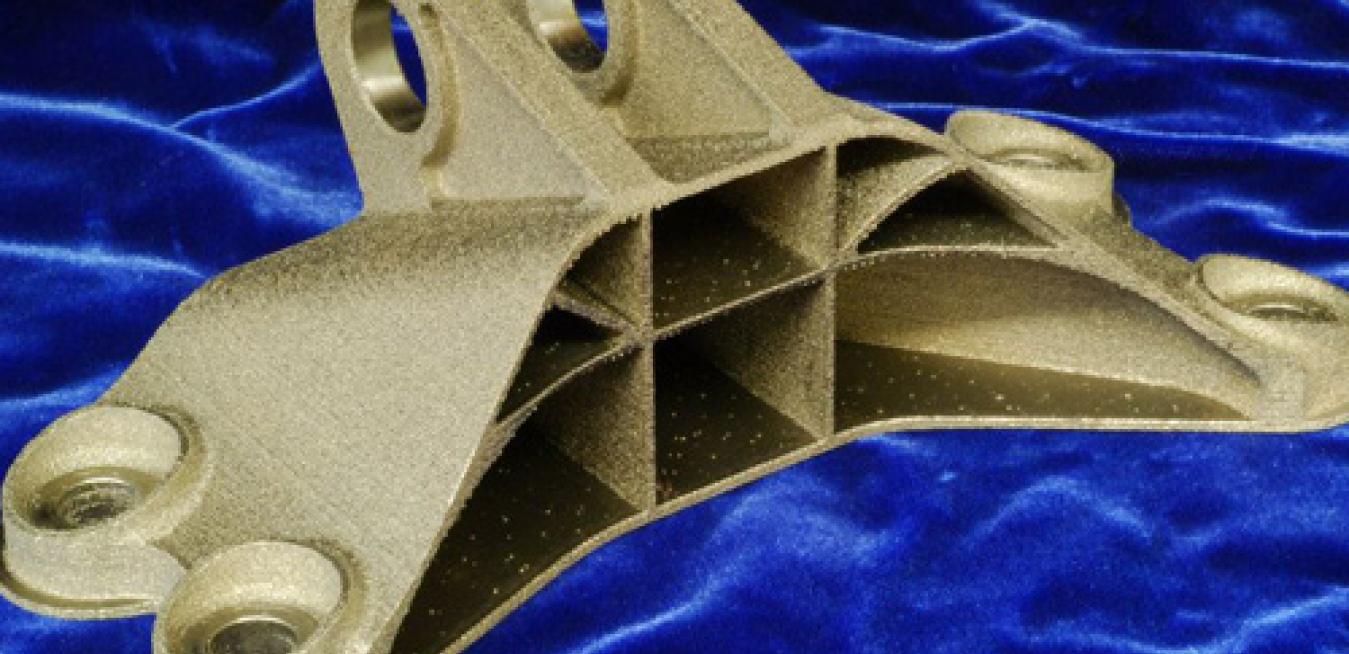

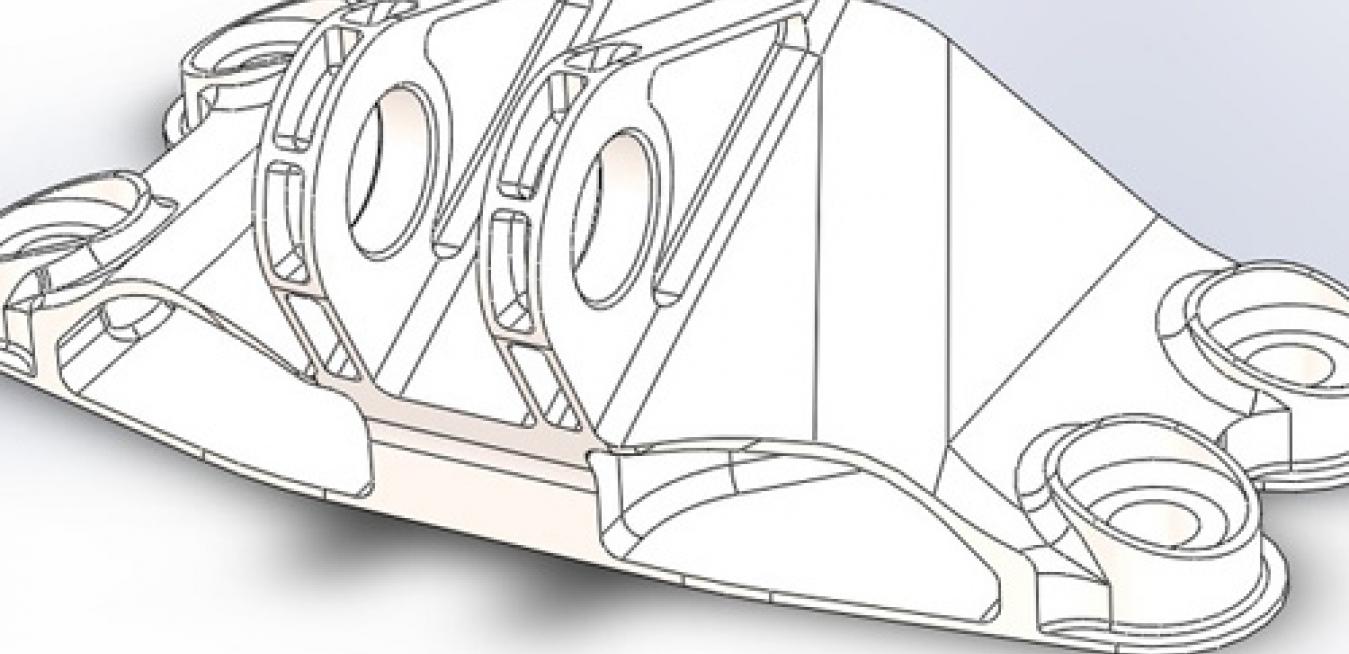

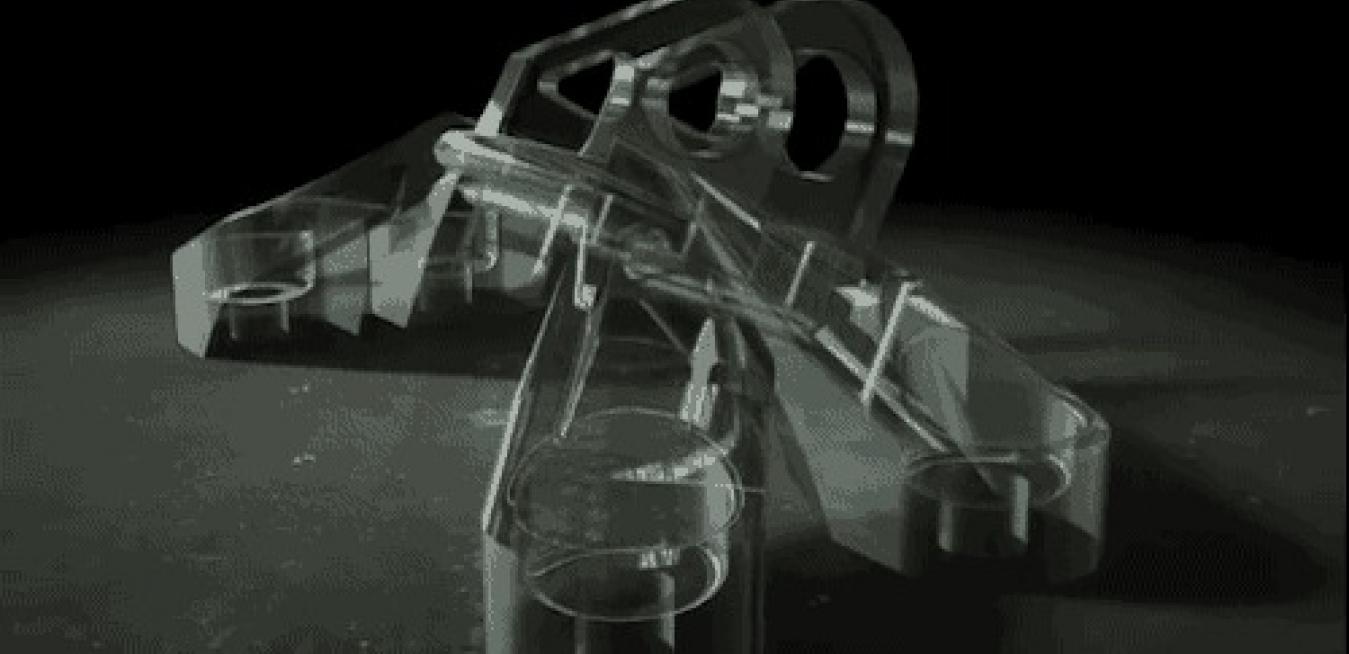

A jet engine bracket designed by M Arie Kurniawan, an engineer from Salatiga in Central Java, Indonesia, came in first place in a global 3D printing challenge held by GE and the open engineering community GrabCAD. Kurniawan will receive $7,000 in prize money. GE and GrabCAD also selected seven other design winners who will divide the balance of the $20,000 prize pool.

The Maker Movement is a vast and diverse community teeming with passionate hobbyists and DIY entrepreneurs energized to build new products and open their designs to others to improve upon them. They share an infectious innovative ethos that anybody can learn from.

Todd Rockstroh has spent the last decade on manufacturing’s vanguard, using lasers to “print” nozzles and other complex jet engine parts from bits of superalloy dust. Despite enormous progress, this process, which is called 3-D printing, remains a tricky terrain. Rockstroh, who is a laser processing expert at GE Aviation in Cincinnati, Ohio, has been working to eliminate as many unknowns as possible, starting with the material. “When we designed the nozzle, we wanted to make it from an alloy that was mature, well known and thoroughly tested, nothing exotic,” he says.

People have been using ceramics to store food, drink tea, and tile their homes for millennia. But GE engineers recently upped the ante and started putting high-grade ceramics inside jet engines.

Many people still struggle with the idea of “printing” things by adding one layer of material on top of another, but Michael Idelchik, who runs GE’s advanced technologies research, is already talking about “printing large portions of jet engines.”

Even in the lofty world of aerospace components, GE’s new 3-D printed jet engine fuel nozzle is a rare bird. Workers build it as a single piece by welding together bits of super alloys dust with lasers. The new nozzle is 25 percent lighter and as much as five times more durable than the current nozzle made from 20 different parts.

Tom Brisken smiles when he sees his jet engine roar down the runway, but it is the smile of a long-distance runner at the end of a marathon. Brisken spent the last decade developing GE’s most advanced large jet engine, the GEnx, as the general manager in charge of large aircraft customer strategies at GE Aviation, and the path to technological breakthrough wasn’t always clear. “There for a while we were biting our nails,” he says.