Let’s change the way we talk about manufacturing.

Too often, the discussion is about how old-line industry is struggling to survive in a world of bold new tech. In reality, digital and additive technologies are transforming manufacturing and growing productivity.

The B2B online retail market is expected to double the size of the B2C online market by 2020. Caught in a digital tsunami with the Fourth Industrial Revolution? Here are five ways industrial manufacturers and distributors can ride the wave, according to Frank Sportolari, Managing Director of UPS Germany.

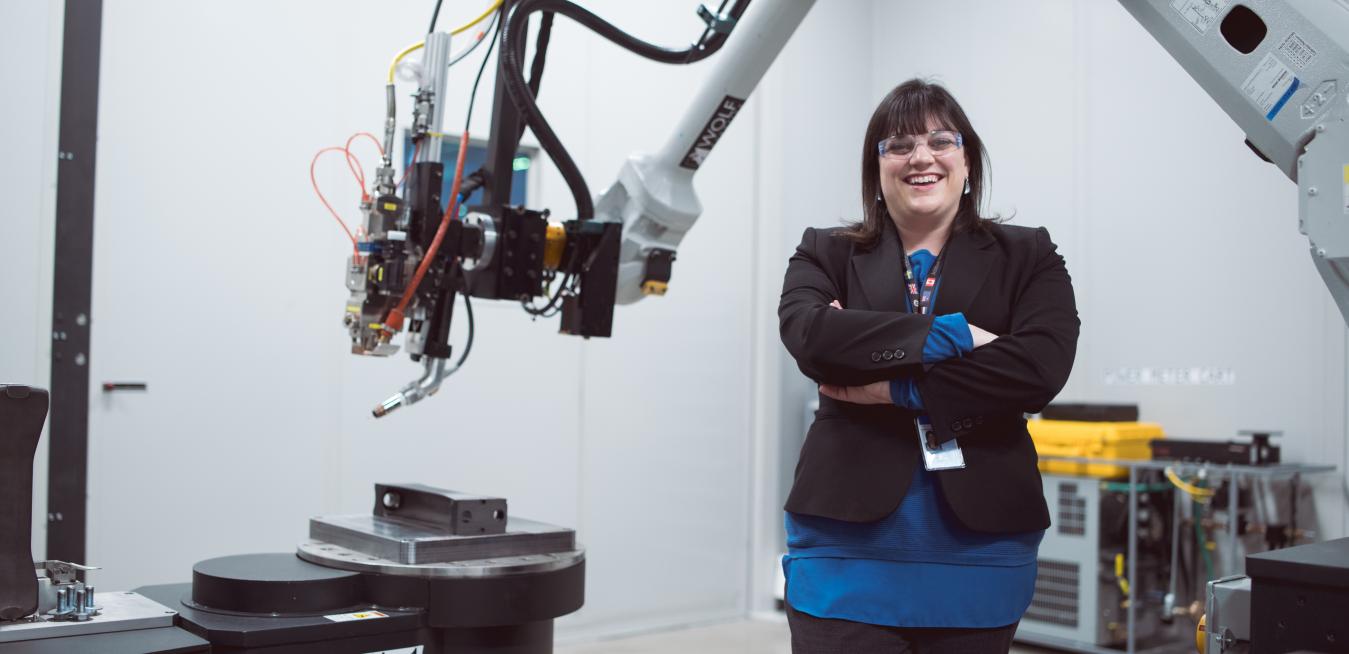

Although women make up a large percentage of Vietnam’s workforce (70% in the agricultural sector[1]) many females still face career barriers. Given GE’s commitment to developing local talent, and expanding opportunities in Vietnam, this series pays tribute to GE Vietnam’s female employees who have made their mark in variety of sectors. For part three of our Chasing Dreams series, we present the story of Phan Kim Nen, a design engineer working for GE’s Oil and Gas business.

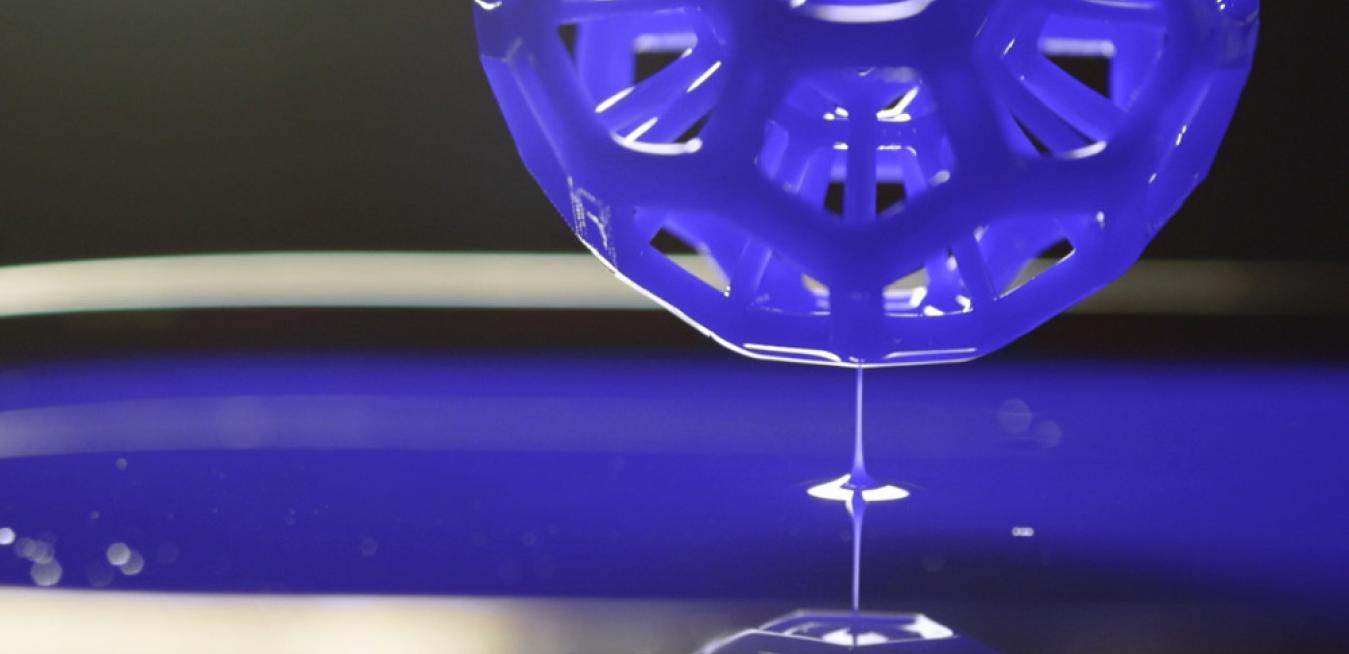

Developed by Silicon Valley startup Carbon, M1 works by plunging a flat build plate into a liquid bath of resin. An ultraviolet LED projector below then flashes a two-dimensional image—a single layer of a 3D object—through the bath’s translucent container bottom and onto the plate.

Located by a new highway exit just minutes from the Pittsburgh airport, the center, which opened in April, is so new even Uber drivers require human navigation. But the center is no mirage.

Consider it a jet engine for the Oompa-Loompas. GE engineers working on the future of aircraft manufacturing recently showed off some of their capabilities. They made a simple 3D-printed mini jet engine that roared at 33,000 rotations per minute (see video above).