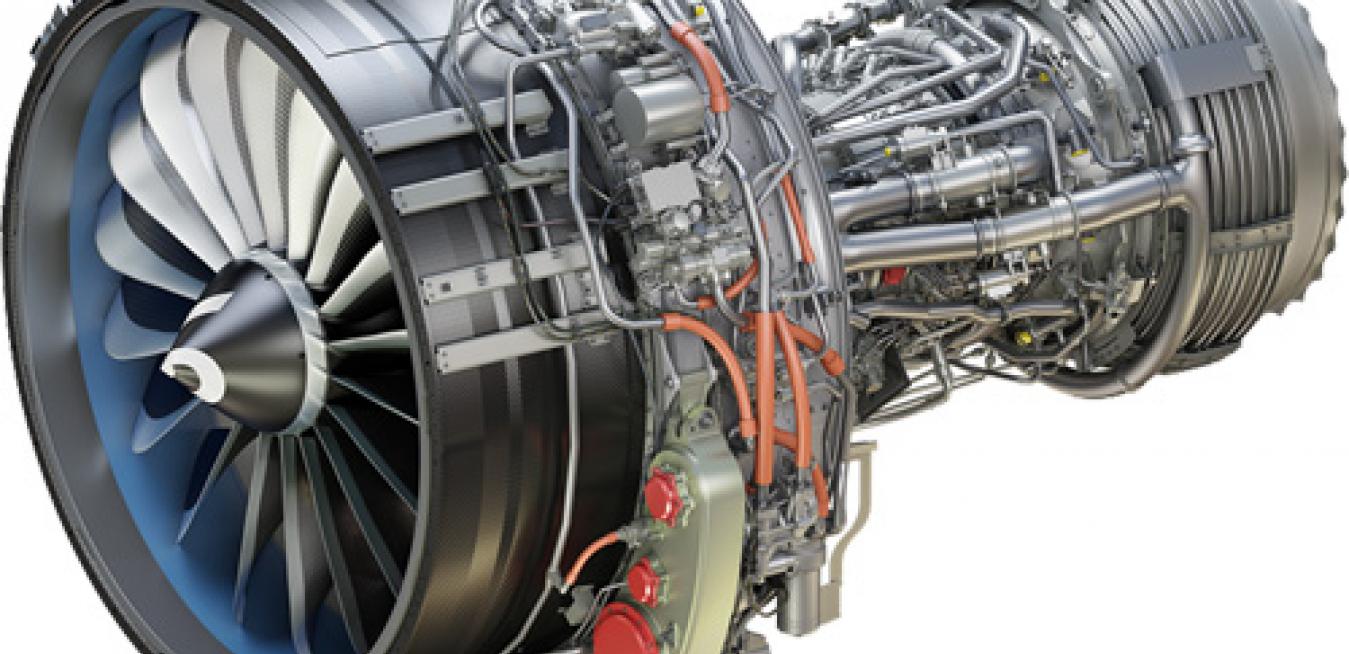

“The design team woke up every morning thinking about it, and went to bed every night thinking about it,” says David Joyce, chief executive of GE Aviation. “It was such a radical change in design.”

Categories

Boeing’s 737 passenger jet became the world’s best-selling aircraft last Wednesday, when the plane builder delivered the 8,000th jet to United Airlines.

United was the first airline to order and take delivery of the second generation of the plane, the 737-200, in 1968. It has since received more than 550 737 aircraft.

Jet engine maker CFM International, a joint venture between GE Aviation and France’s Snecma, completed a design freeze for its latest jet engine that includes for the first time components made from advanced ceramic composites and parts manufactured using 3-D printers. “All of our testing and design work leading to this moment demonstrates that we are on track to meet all of our program commitments,” said Gareth Richards, LEAP program manager at GE Aviation.