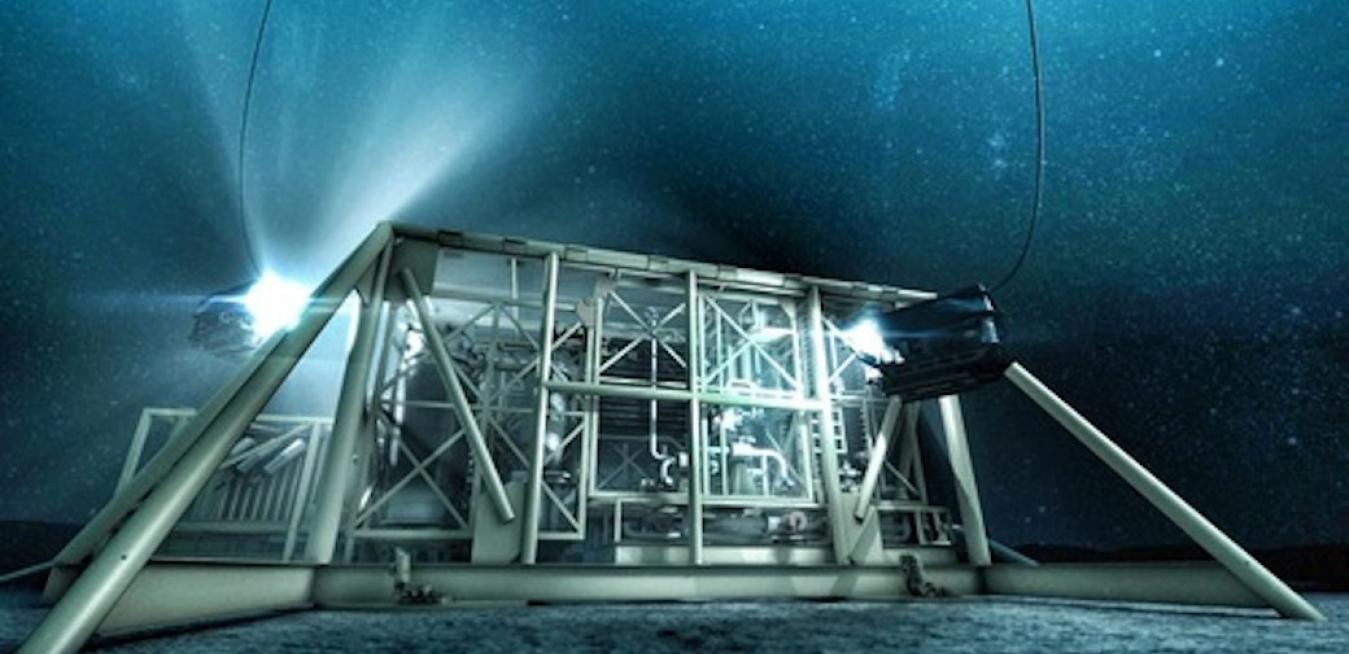

That’s the type of incredibly harsh environment that GE researchers are competing with as we design electrification equipment for our customers that will power oil and gas processing functions reliably on the seabed.

How can they be better leveraged?

There are lots of ideas out there, but as we argue in a new paper, one of the most effective ways for the labs to increase their economic impact is for them to “go local” and engage more in the advanced industry ecosystems within which they reside.

Getting shale gas out of the ground is one thing. But taking it to customers is quite another.

American pipeline operators are investing as much as $40 billion every year to maintain, modernize and expand their networks. The shale gas boom is putting operators under pressure to move more gas to market faster and more safely, and many U.S. pipelines have been in service for at least two decades.

GE machines are working deep underground, on the International Space Station, and even in the interstellar space. Now the sea floor is opening up to underwater factories designed to recover oil and natural gas deposits that used to be out of reach.

Jeff Immelt, GE chairman and CEO, writes in the company’s 2013 Annual Report, which GE released today, about the benefits of looking at innovation with a broad lens.

The theme of the Annual Report, and Immelt’s letter to shareowners, is “Progress,” which, he writes, is reflected in GE’s ability to spread ideas and technology across the entire company.

Speaking at the Energy 2020 summit in Washington D.C., GE Chairman and CEO Jeff Immelt announced today that GE will invest an additional $10 billion in “ecomagination” research by 2020, to reach a total of $25 billion since the program’s inception a decade ago.

Ecomagination is GE’s company-wide push designed to develop cleaner and more efficient technologies. It has generated $160 billion in revenues since 2005.

Nexen’s Buzzard offshore complex is a system of three oil platforms anchored in the cold and choppy Atlantic some 62 miles northwest of Aberdeen, Scotland. Nexen, a Canadian energy company, designed the platforms to produce 200,000 barrels of oil per day, making the field one of the largest in the North Sea. But several years ago, one of Nexen’s three main power turbines generating Buzzard’s electricity experienced a series of “trips” – or power fluctuations that result in a turbine shutdown, putting production in jeopardy.