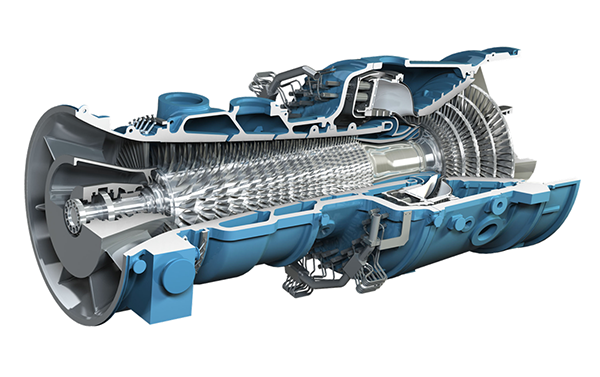

GT13E2 gas turbine operation and maintenance upgrade

About 30% of reported operational issues in GT13E2 fleets concern operational reliability, requests for maintenance optimization, and start-up consistency. Our dynamic operation and maintenance (O&M) upgrades can be customized to solve these issues—and add power output value to your turbines.