Search GE Gas Power

What are you looking for?

Or start with a popular search:

Recommended resources

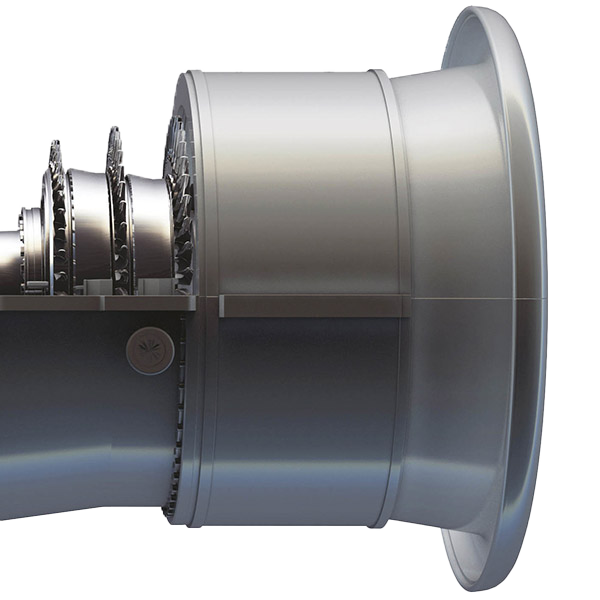

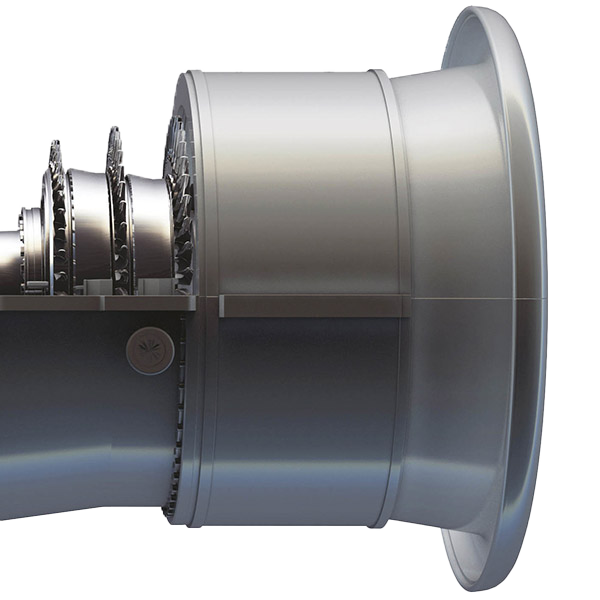

6B exhaust plenum and frame upgrade

GE’s Corrosion and Heat Resistant Original Equipment Manufacturer (CHROEM™) improved exhaust systems applies the latest GE technology to extend life and provide economic benefits through increased reliability, maintainability, and service life for operators.

New

plenum design

Reduced

maintenance

Installation

without removing rotor

Benefits

What can upgrading do for you?

GE’s Advanced Extendor combustion interval extension upgrade was developed to extend the duration between planned maintenance inspections, which can increase the availability of your gas turbine—and even eliminate certain types of inspections—and reduce maintenance costs.

How does this upgrade work?

CHROEM exhaust plenums by GE utilize an internal floating liner design, which allows for more efficient absorption of thermally induced stresses during unit operation. CHROEM exhaust plenum assembly components also provide other advanced features, such as:

- Drainable liner floor with optional jacking port

- Double-sealed wing door

- Cool shell and flange design

- Improved expansion joint design

CHROEM exhaust plenum assembly components are designed for installation with the turbine rotor and aft diffuser in place, saving both time and installation costs. CHROEM components also interface smoothly with downstream ductwork, and can be easily installed on older model B, C and E frame turbines.

Gas Power

Gas Power engineers cleaner, more accessible energy that communities depend on to power growth and prosperity.

Contact usDecarbonization - the future of energy

See how Gas Power is helping to build a world that works.

Learn more