Search GE Gas Power

What are you looking for?

Or start with a popular search:

Recommended resources

Capacity performance package, powered by axial fuel staging

The 7E capacity performance package is powered by axial fuel staging (AFS) and corrected parameter control (CPC), which help increase output in DLN1 / DLN1+ systems for wider load operating ranges and consistent, compliant emissions.

Up to 8%

more output, no increase in NOx or CO

35% load*

as low as 30MW emission compliant load

108% load*

up to 7MW more emission compliant peak

Fast facts

Applicable gas turbine models:

Time to install

< 5 days

Additional info

Installs during any planned maintenance

Benefits

What can upgrading do for you?

The 7E capacity performance package improves performance in DLN1 and DLN1+ combustion systems by combining two robust technologies: axial fuel system and corrected parameter control.

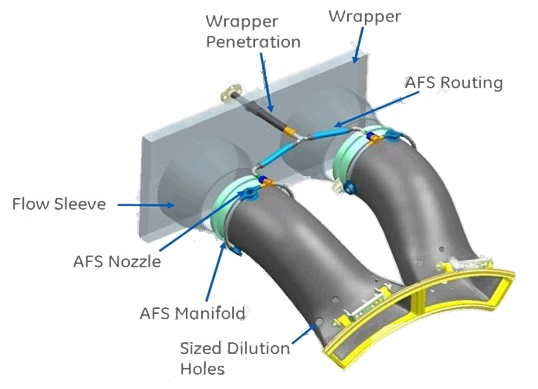

Axial fuel staging (AFS) helps increase the emission-compliant operating range as part the package. AFS hardware pairs with corrected parameter control (CPC) software, which helps enhance existing turbine control and improve control of unit exhaust temperature. GE Gas Power can modify existing combustion systems to provide more power without negatively impacting existing emissions signature.

The technology was initially developed for operational flexibility in 7E turbines. Given its proven capability, use has been expanded into the F/HA fleets as well.

How we get you there

The capacity performance package promotes start up reliability as well as combustion enhancements. Its software helps ensure the turbine is ready to start with pre-start systems checks and monitoring software, for example.

By introducing gas fuel into the head end of the transition piece through a new fuel circuit, AFS helps achieve notable combustion enhancements. In addition, a new wrapper system with Nimonic transition pieces is deployed.

At the same time, CPC helps enhance the existing static turbine control with an all load temperature reference, which is updated as ambient conditions change. This enables better control of unit exhaust temperature and emissions.

*With inlet bleed heat IBH. Performance may vary based on NOx ratings.

Fuel savings and carbon reduction

AFS value calculator

Achieve lower turndown, emissions, and maintenance costs with GE's Axial Fuel Staging (AFS) gas turbine upgrade.

Gas Power

Gas Power engineers cleaner, more accessible energy that communities depend on to power growth and prosperity.

Contact usDecarbonization - the future of energy

See how Gas Power is helping to build a world that works.

Learn more