Benefits

9EMax technology innovations

With the 9EMax turbine, you can reduce fuel costs by running up to 37% efficiency in simple cycle, and up to 54% in combined cycle. Annual fuel costs could shrink by as much as $5 million, while creating the potential for up to $6 million in additional revenue.

A game-changing package

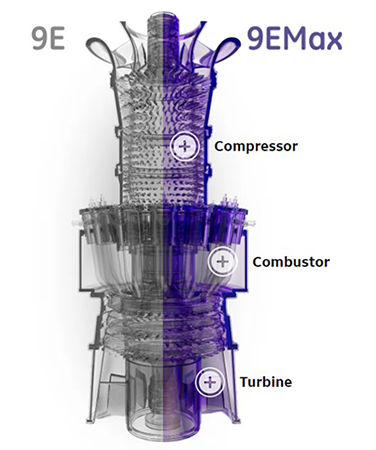

A re-engineered turbine module with new casings, rotor, advanced exhaust diffuser, and four-stage hot gas path—the 9EMax is delivered as a fully assembled, modular solution. Its components are more accessible, including a reconfigured diffuser for efficient maintainability.

Features

The same configuration as your 9E gas turbine

Compressor

17-stage axial flow

- First 7 stages, highly corrosion resistant material (450 SS)

- 13.2:1 pressure ratio

- Proven aerodynamic configuration

- Inlet guide vane (IGV)

- Inlet bleed heat

- Fast start capable

- No hardware modification = no impact on failure modes risks

Combustor

Adjusted for 9EMax cycle

- Natural gas, distillate oil

- New cross-fire tubes

- DLN1+ low NOx, 15ppm

- Future capabilities for heavy fuel oil and syngas

- 14-can annular chambers

- Combustion upgrade to 32,000 FFH system

- Modified liner dilution hole size for emission compliance

(DLN only)

Turbine

Built for availability

- Simple cycle to combined: 37% efficiency up to 54%

- Simple cycle to combined: 146 MWS up to 210

- Advanced radial diffuser

- Same exhaust energy as 9E.03 gas turbine

- Four-stage hot gas path proven to reduce cycle fatigue

- Four-stage E-class rotor architecture

- Re-engineered shell and exhaust frame

Further reading

Find out more

GE Reports

Infographic

Customer stories

-

Sokolovska Uhelna

-

Stadtwerke München

-

Sokolovska Uhelna

-

Stadtwerke München

Sokolovska Uhelna

GE injected the latest technology into a full turbine upgrade for Sokolovska Uhelna in the Czech Republic. Evolving the 9E.03 to a 9E.04 (three-stage turbine to four-stage configuration) allows more energy to be extracted—but also modernizes the turbine for another 20 years of operation.

fuel gas efficiency

146 MW

in simple-cycle baseload

“We’ll do a rotor life extension on that front-end section to give it 100,000 additional hours. We can do this because the compressor configuration of the 9E.03 and 9E.04 are identical.”

Robert Colwell

Senior Product Manager, Power Services, GE Power

Stadtwerke München

GE will upgrade two 9EMax gas turbines for German utility Stadtwerke München (SWM)—a power plant at the heart of Munich. The upgrade of these turbines and two A39 generators can increase plant output and boost operational flexibility per gas turbine.

30 MW

increase in plant output

Up to 3%

efficiency boost per turbine

“We are proud to deliver a solution to SWM and help them successfully full their commitment in providing heat and power to the vibrant city of Munich.”

Michael Rechsteiner

Vice President, GE Power Services, Europe

Videos

Learn how we can help

Our services team works around the world with companies optimizing their products to be greener and more efficient.

GE’s 9EMax Four-stage Turbine

World’s First 9EMax Commissioned at Tepco’s Futtsu Plant in Japan

9EMax Gas Turbine Solution: First Fire Announcement

9EMax Gas Turbine Upgrade: Game-Changing Plant Performance