Benefits

For this E-class upgrade, advanced is more than just a word

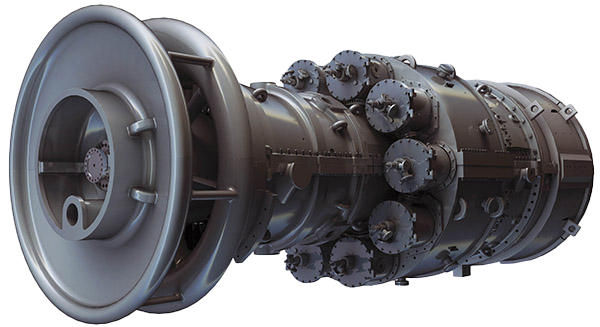

It means a flexible gas turbine fuel nozzle solution

Building on GE Aviation’s experience, GE Gas Power has advanced emissions performance and operational flexibility of the advanced secondary fuel nozzle. Using 3D printing, its manufacturing process is flexible, fast, and economical.

This new product allows for a solution that provides flexible performance outcomes for 7E and 9E turbine profiles. So the same hardware solution can give you low turndown today and peak MW as your future needs change.

It means better environmental and cost outcomes

The reconfigured advanced secondary fuel nozzle provides a rapid, cost effective energy boost for power generators. The redesigned turbine fuel nozzle lowers NOx, allowing increased emissions-compliant megawatts by increasing the unit firing temperature, with no hardware tuning. That simple shift can yield as much as $250,000 in a 7E gas turbine annually, with an improved power rating. These outcomes were tested and proven in the field as of July 2021.

It means easy to install upgrade without a long outage

Operators can expect rapid returns with the advanced secondary fuel nozzle—and quick installation as well. Some upgrades require waiting for an outage or scheduling one specifically. This nozzle upgrade is easy to install with no extended outage needed. Installation can be completed in as little as 48 hours.

Customer story

“We couldn’t have asked for anything better.”

See how our ASFN helped Cooperative Energy deliver reliable power to their stakeholders.

Frequently asked questions

Learn more about our 7E / 9E ASFN upgrades

Which turbine models benefit from the advanced secondary fuel nozzle upgrade?

The ASFN upgrade is applicable to E-class gas turbine models:

- 7E

- 9E.03 and 9E.04

This flangeless configuration is compatible only with gas powered DLN1 and DLN1+ systems.

What is the expected time to install for the ASFN upgrade?

For both 7E and 9E turbine types, installation can be completed in 2 days. There is no specific inspection type required for installation—any scheduled 2 day shutdown can easily accommodate ASFN upgrade installation.

What benefits can the ASFN upgrade yield for 7E turbines?

Up to 37%

lower NOx emissions

Up to +55˚F

emissions compliant peak fire

6 – 8%

greater emission-compliant turndown

As low as -20˚F

ambient NOx compliance range

What benefits can the ASFN upgrade yield for 9E turbines?

Up to 33%

lower NOx emissions

Up to +55˚F

emissions compliant peak fire

6 – 8%

greater emission-compliant turndown

As low as -15˚F

ambient NOx compliance range