Frequently asked questions

Learn about fuel combustion for gas turbines!

What is thermal combustion in a gas turbine?

Combustion: A rapid exothermic process that delivers high-temperature products. But, let’s break that down.

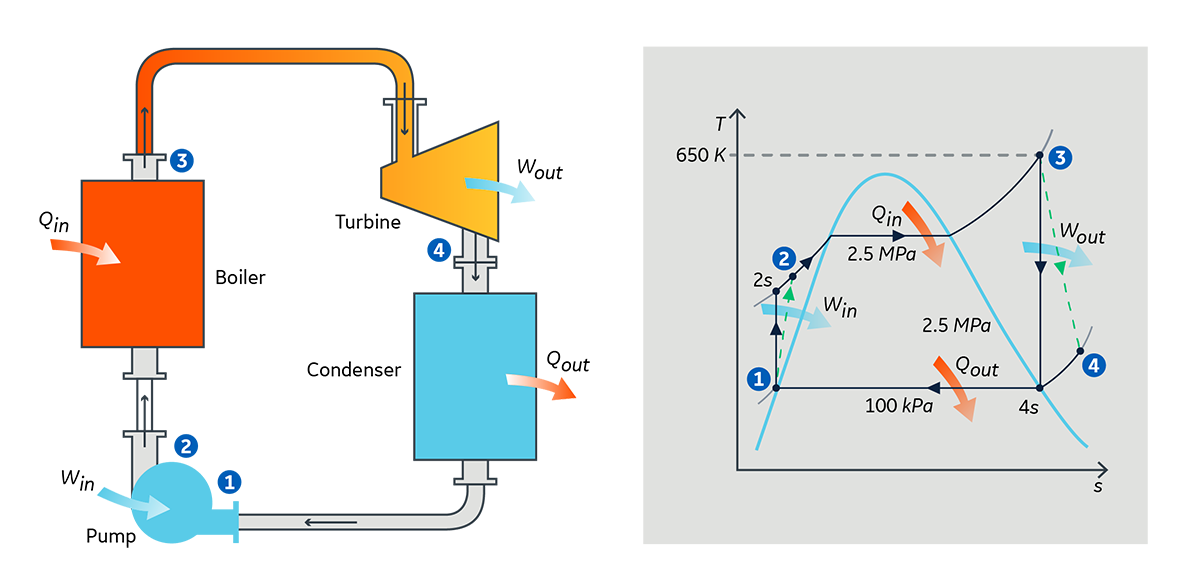

Gas turbines generate power using pressurized air. The air is heated in a “combustor” and then it expands through the turbine. In turn, the turbine spins a generator that creates electricity. Another key part—the air compressor—is also powered by the turbine as it rests on the same shaft, pushing air into the combustion chamber. This whole combustion process is called the “Brayton Cycle”.

How does combustion keep things up and running?

Efficient combustion is a key factor in gas turbine technology. Fuel-to-power benefits depend on operating temperatures; higher cycle temperatures makes for higher efficiency.

When maintained and modernized, combustion efficiency sustains much of the way we live, work, and play:

- Manufacturing and operating gas-powered and hybrid vehicles

- Heating our homes and schools

- Preventing power outages for cities, municipalities, and cooperatives

- Backing up power for important places like hospitals

- Maintaining uptime for industry and the data centers it depends on

How does a combustion turbine work?

What is the science behind it all? Important combustion chemistry to know:

While fuel can have a great diversity of forms, the natural gas that powers gas turbines is burned for its chemical energy. But the combustion process can’t start without a reliable ignition. The fuel reaction in a flame chamber kicks off the whole cycle.

Important combustion machinery: put simply, a gas turbine is an air machine composed of three main parts …

- The COMPRESSOR is what takes in air from outside of the turbine and increases its pressure at hundreds of MPH, then feeds it to the combustion chamber.

- The COMBUSTOR is what actually burns the fuel and produces high-pressure gas. The mixture is burned at temperatures of more than 2,000 °F to expand within the turbine sectionat high velocity.

- The TURBINE extracts the energy from the gas in the combustor. This is done with an array of stationary and rotating airfoil blades. Finally, the new kinetic energy from the blades runs a generator that produces power.

What contributes to the combustion efficiency of a gas turbine?

There is a balance required between the fuel, the environment, and the machinery to ensure turbines are feeding off of combustion to the best of their ability.

- Believe it or not, cleanliness of the operating area is key, so that no particles are let into the combustion chamber.

- High-quality fuels—ones that are filtered—burn more seamlessly throughout the Brayton Cycle.

- Heating fuel in the range of 365 °F adds to gas turbine efficacy, as it reduces the amount of fuel for desired firing temperatures.

- Combustors must sustain their flame at all times, and up-classing them helps operate under high temperatures and air velocity.

- With the right services, combustor service life can be extended to work with new technologies and go beyond “expiration date”.

Since higher temperature makes for higher efficiency, the expanding in power plant turbines can reach up to 2,300 °F. However, some of the metals they're made from can’t withstand temperatures above 1,500 °F.

How does combustion relate to the environment?

Efficiency and sustainability go hand in hand. Rapid combustion does result in emissions, but as turbine technology progresses, GE engineers its future tech for lower carbon footprints. In addition:

- Higher temperatures result in higher efficiency. That means CO2 and LNG particulates are reduced when burning, and the turbine maintains a consistent firing temperature.

- Premixed fuel is ideal for low NOx emissions. As the mix is created with optimum sustainability in mind, combustors throw high thermal energy with lower emissions.

- Low-sulfur fuel takes away from the accumulation of sulfur dioxide and much of the nitrogen oxides that cause acid rain.

What kind of maintenance and upgrades improve gas turbine combustion?

As turbine technology evolves, small but important changes modernize how combustion power.

There are several configurations of . From heavy frame engines, steam turbines, to aeroderivative models—the following can make all the difference:

- Life extension: This is a way to boost the longevity of a turbine by “rejuvenated” parts and updating prime components.

- Lower emissions upgrade: This is the “efficiency = reduced NOx and CO2 formula”. It makes the combustor more like a car’s catalytic converter .

- Hydrogen modification: Giving a turbine the option to burn hydrogen doesn’t just increase efficiency, the H2 makes it greener.

- Modernized fuel nozzles: Fuel nozzles channel the fuel and air that makes combustion possible, and GE 3D prints new versions for improved power output and lowered emissions.

- Non-optical flame detectors (NOFD): An NOFD senses and improves the reliability of the flame—and a stabilized flame makes for protected availability and uptime.

How can we connect the dots?

Upkept and upgraded turbines help power plants keep their uptime. And understanding the ins and outs of combustion is part of that!

GE’s maintenance and repair services keep the turbines the world depends on in careful hands. With our experts pushing technologies to new capability, the future of combustion is burning bright.