Overview

Playing a vital role in developing construction projects across the Middle East for over 50 years, Saudi Cement knew they needed an upgrade to improve reliability and efficiency in their manufacturing process.

The challenge

Power supply is both a key input, as well as one of the largest costs in the manufacturing process. Therefore, a reliable, efficient electricity supply is essential to the continuous operations of the facility, as well as market competitiveness.

The solution

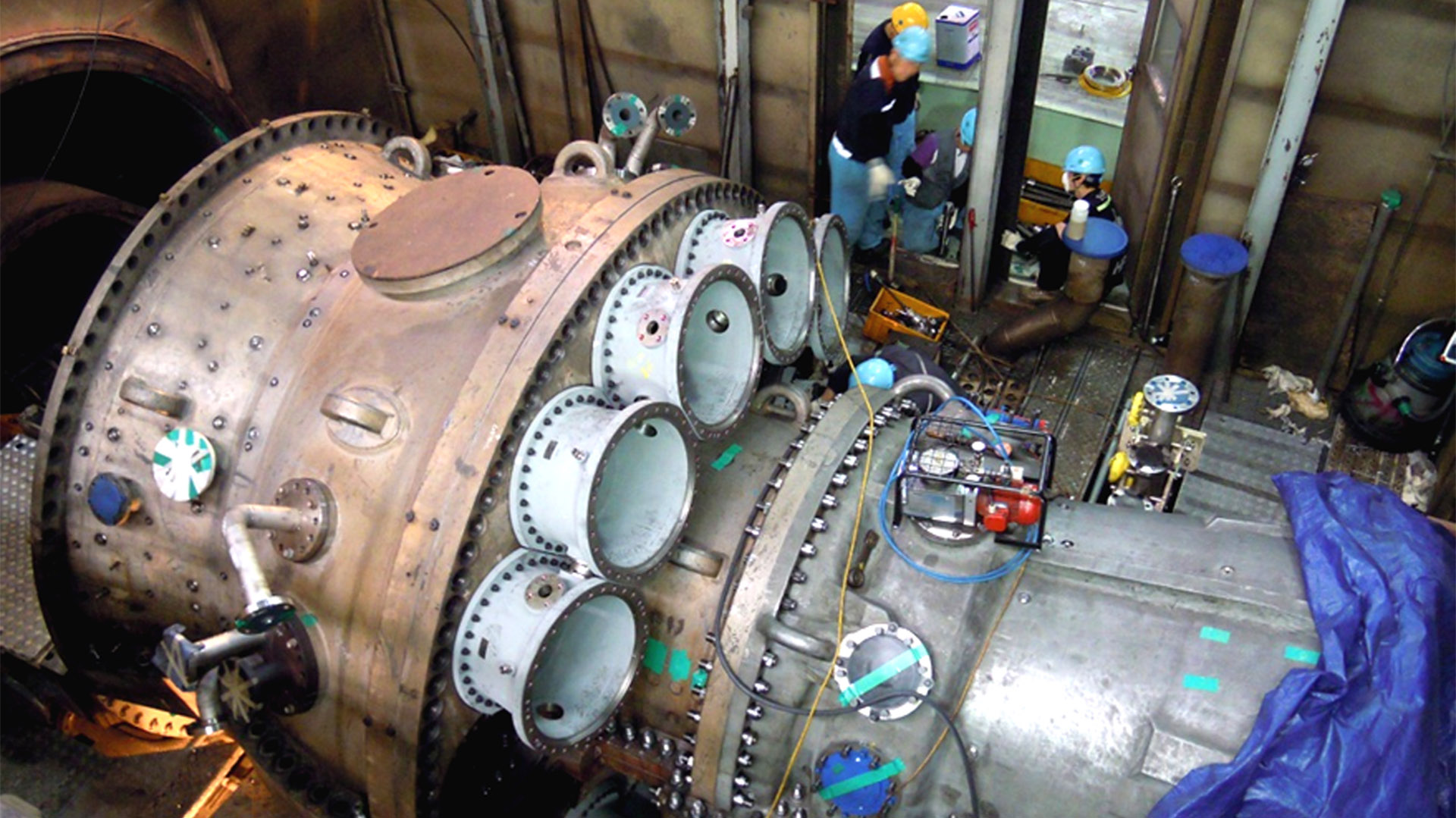

The AGP upgrade of its three 6B gas turbines will allow Saudi Cement to become more self-sufficient in power production, achieve greater cost efficiencies by significantly saving fuel and enable the company to better serve the industry’s supply chain in alignment with the Saudi National Transformation Program’s goal to improve fuel utilization in electricity generation to 40% by 2020.

Outcomes

Boosting capacity and efficiency with the Advanced Gas Path solution

23 megawatts

increase in capacity

efficiency increase per turbine

In a historic deal that marks the first time GE’s Advanced Gas Path (AGP) solution will strengthen power generation productivity for the cement industry globally, Saudi Cement will upgrade three GE 6B gas turbines at its Hofuf plant to increase capacity by 25 megawatts and efficiency by up to 3.3% per turbine.

GE’s AGP solution offers customers a range of performance advancements that can be tailored based on their operational, business and energy market needs. Over the past eight years, it has delivered significant market-based benefits around the globe, including saving customers $775 million a year and providing about 7 gigawatts of additional power capacity. AGP technology is now installed on 435 units across five GE gas turbine fleets in 39 countries.