Industry recognition

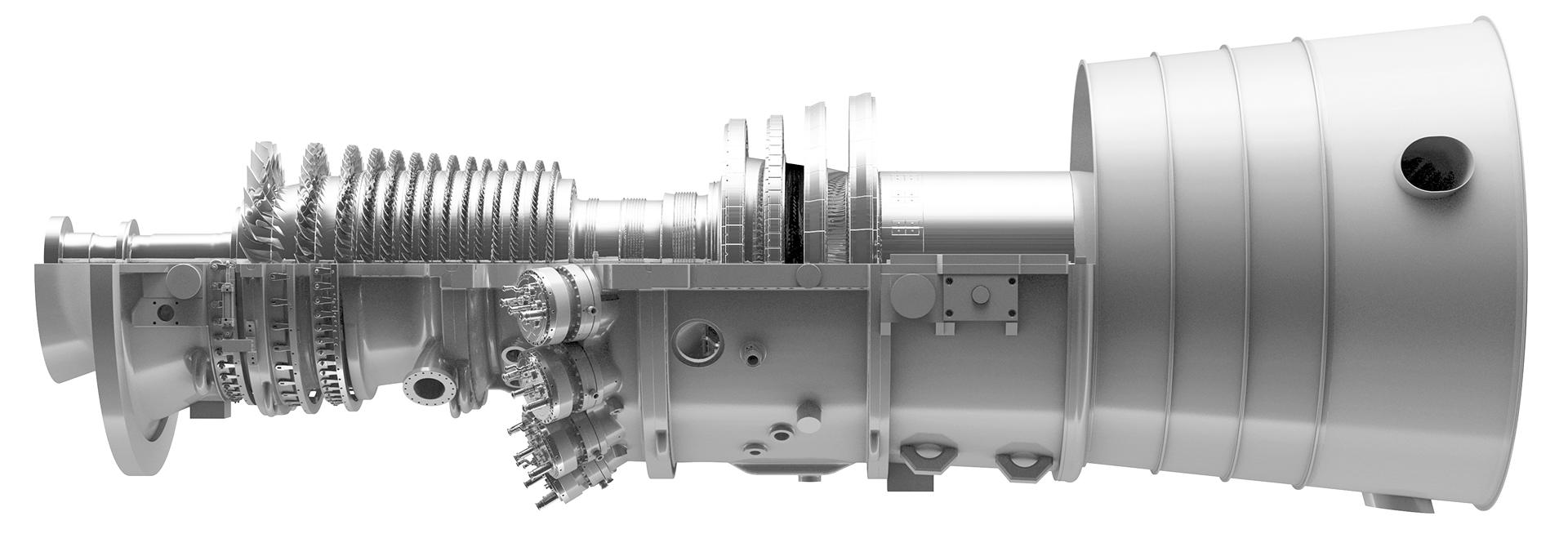

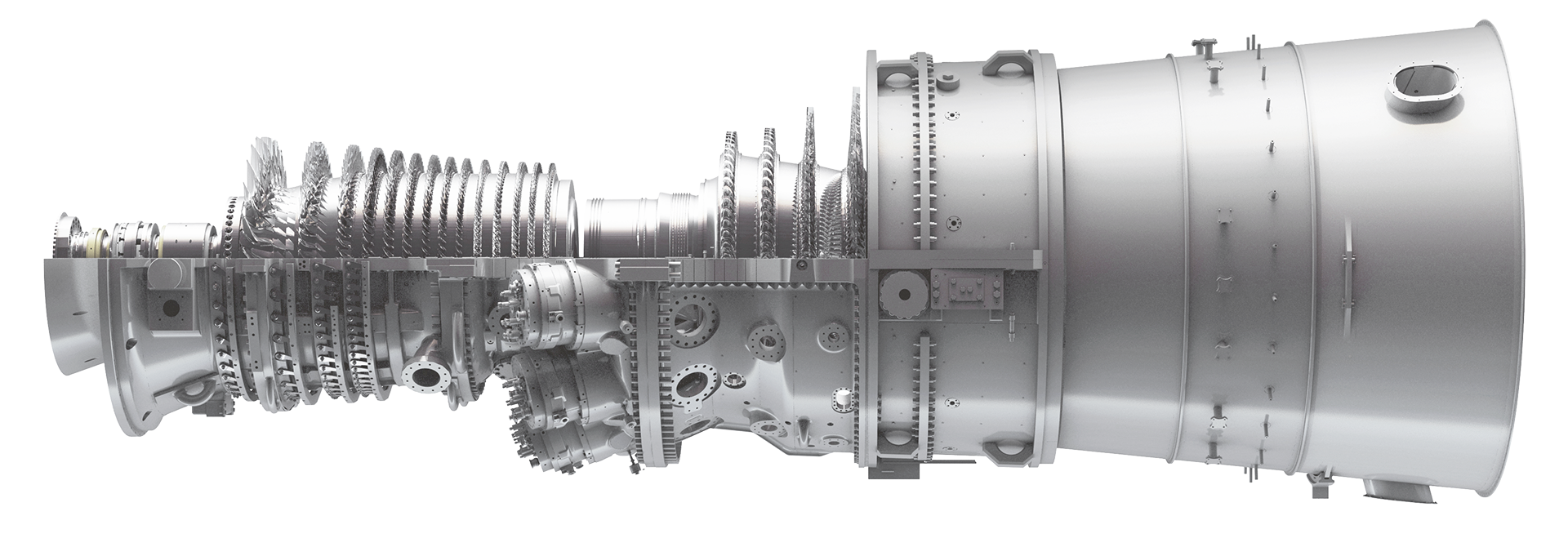

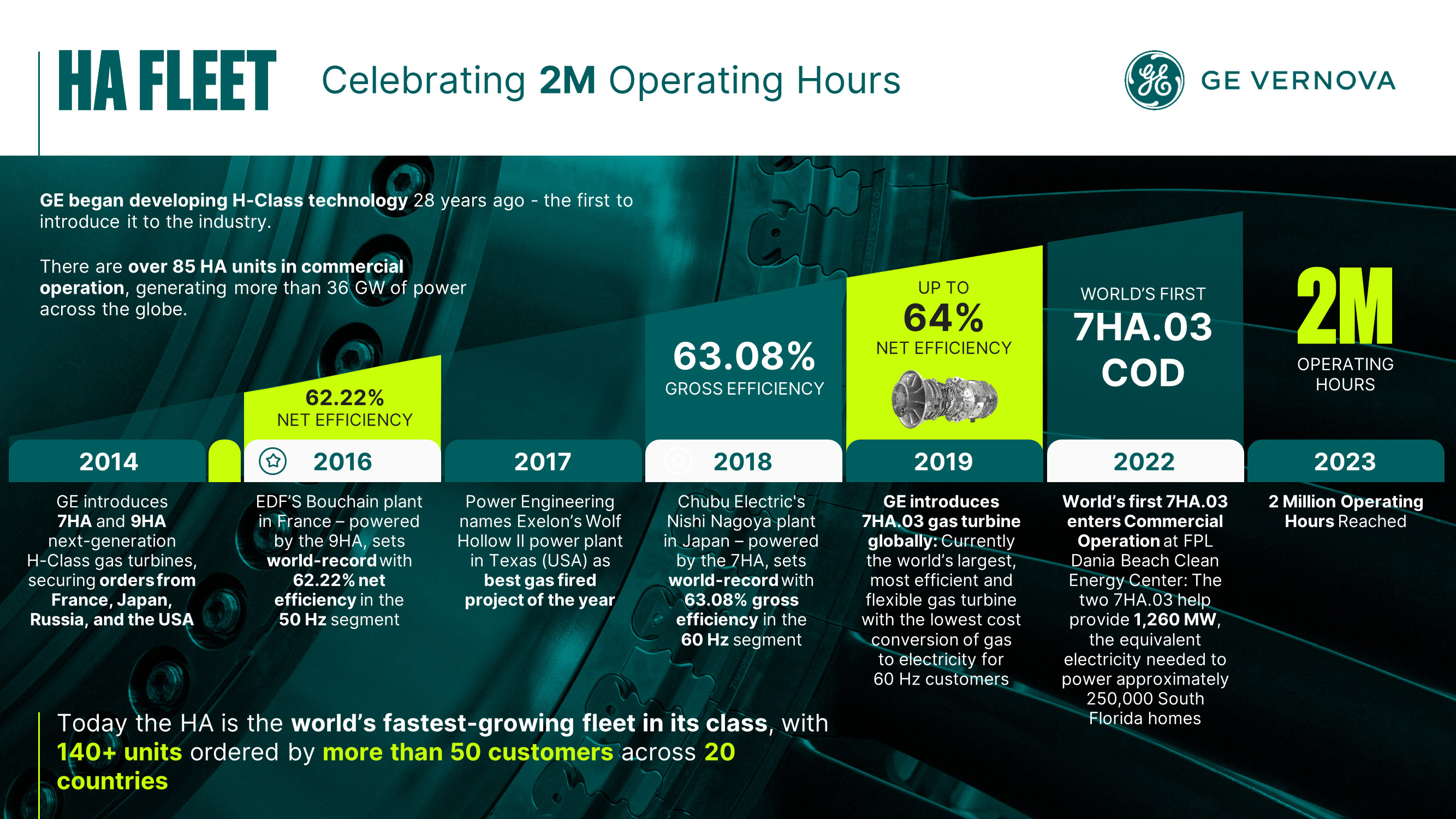

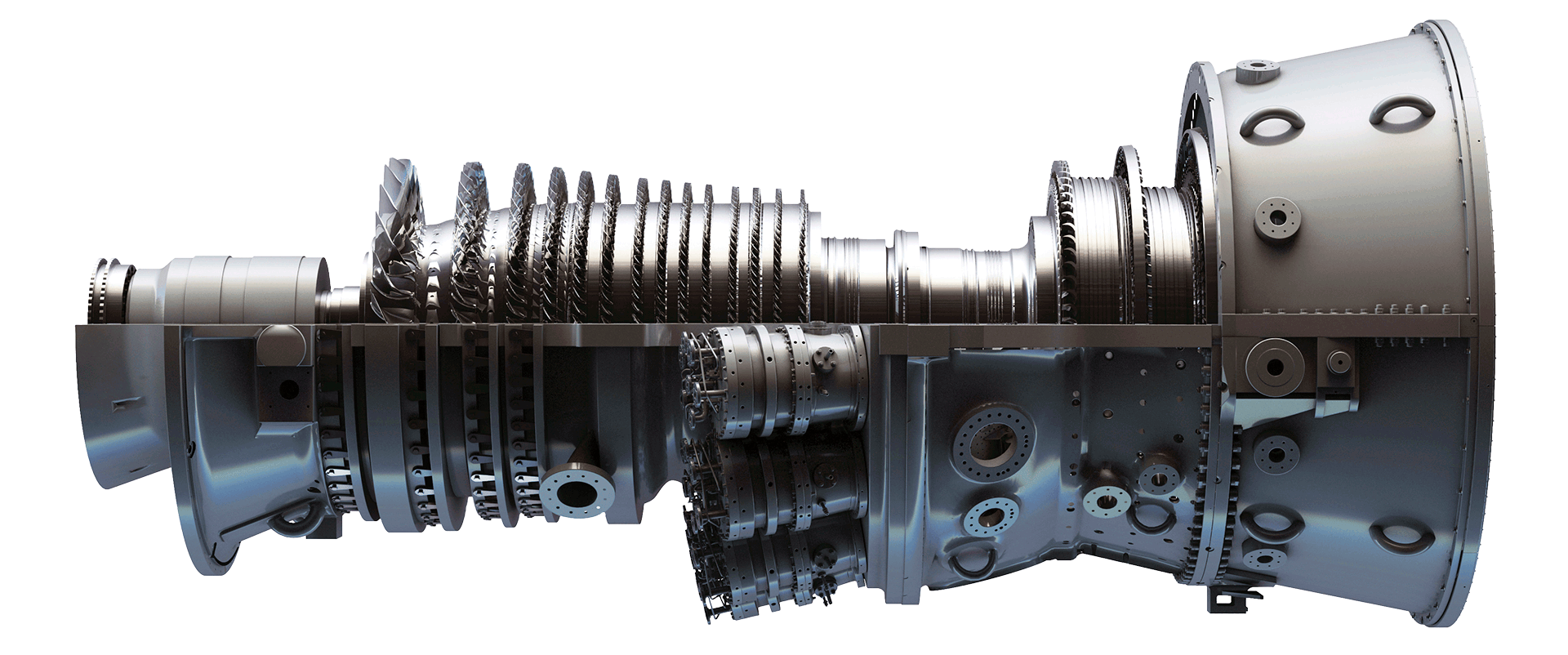

GE is the only original equipment manufacturer (OEM) that has been previously recognized by a 3rd party for setting two world records for powering the most efficient plant in an H-class combined-cycle (CC) application: 63.08% gross CC efficiency at Chubu Electric’s Nishi Nagoya power plant in Japan (7HA, 60Hz), and 62.22% net CC efficiency at EDF’s Bouchain power plant in France (9HA, 50Hz).

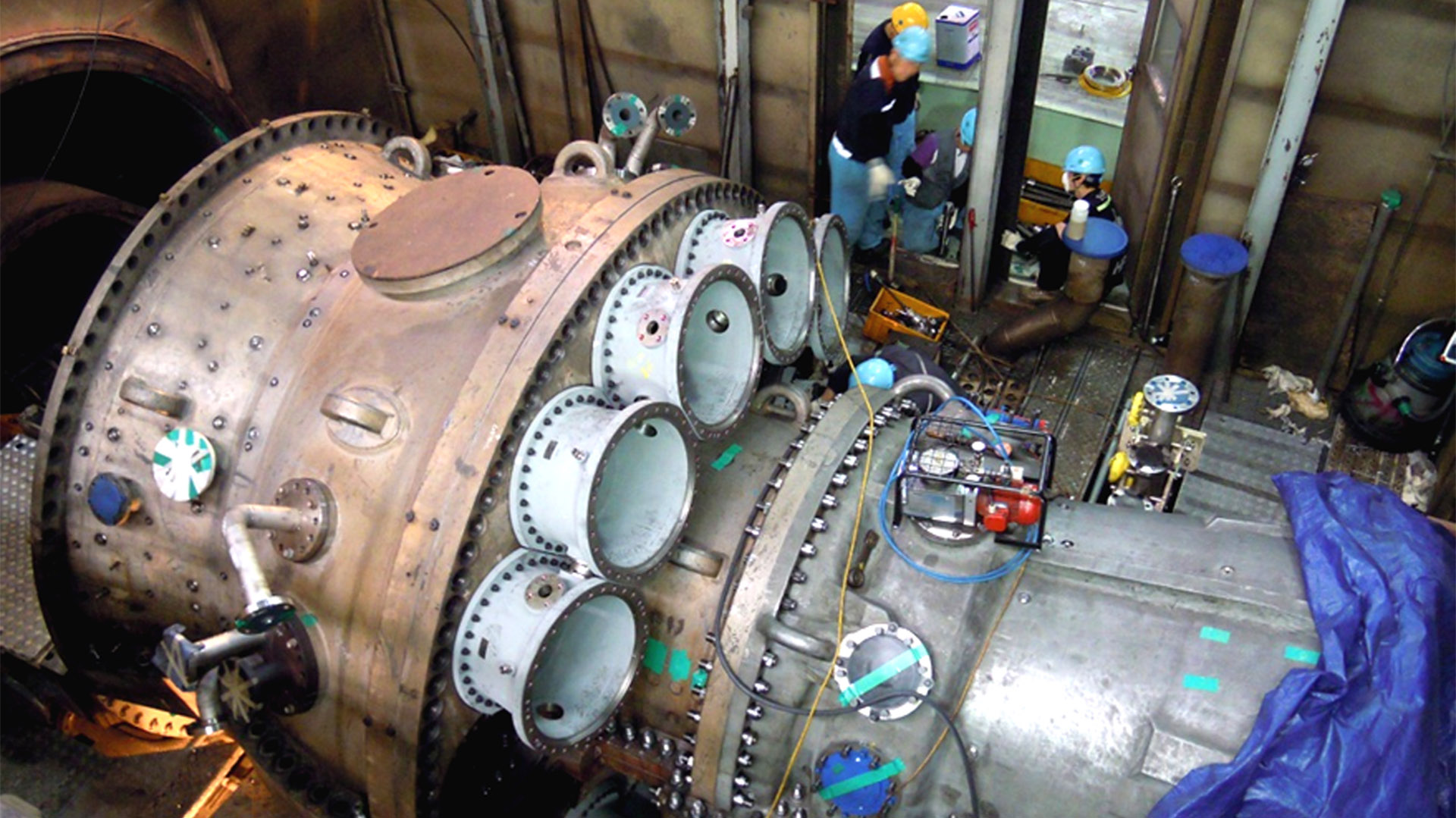

In 2021, Southern Power Generation’s 1.4 GW Track 4A power plant (Sultan Ibrahim Power Plant), a natural gas-fired power plant in southern Malaysia—equipped with the first commercial GE 9HA.02 gas turbines—was recognized by POWER Magazine as their “2021 Power Plant of the Year” and by Diesel & Gas Turbine WORLDWIDE as “Power Plant of the World,” a meaningful model for balancing climate awareness, energy affordability, and reliability.

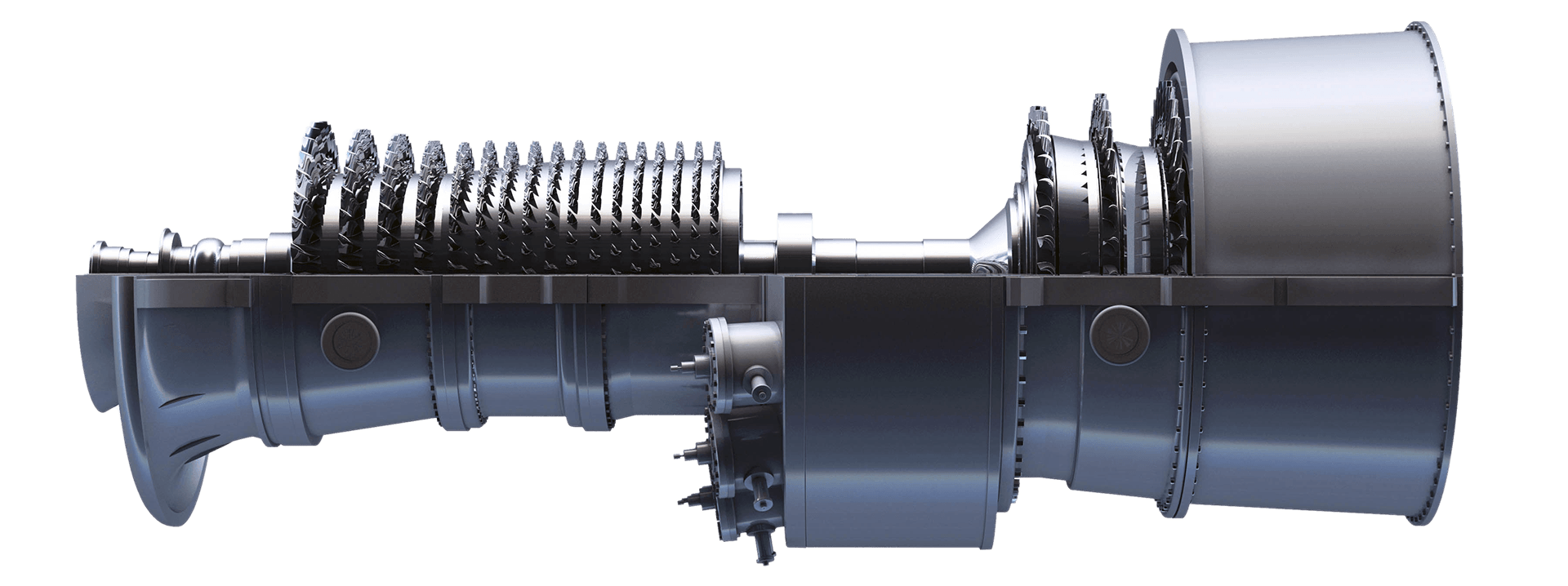

In 2020, GE Gas Power and New Fortress Energy announced that the Long Ridge power plant in Ohio will be the first purpose-built hydrogen-burning plant in the United States—and the first worldwide to blend hydrogen in a GE H-class (7HA.02) gas turbine.

In addition, GE’s HA technology was adopted at China Huadian Corp’s Juliangcheng plant to help accelerate the retirement of existing coal-fired capacity and replace it with new, highly efficient combined-cycle gas turbines—an important role that earned POWER Magazine’s “Reinvention Award.”