Search Gas Power

What are you looking for?

Or start with a popular search:

Recommended resources

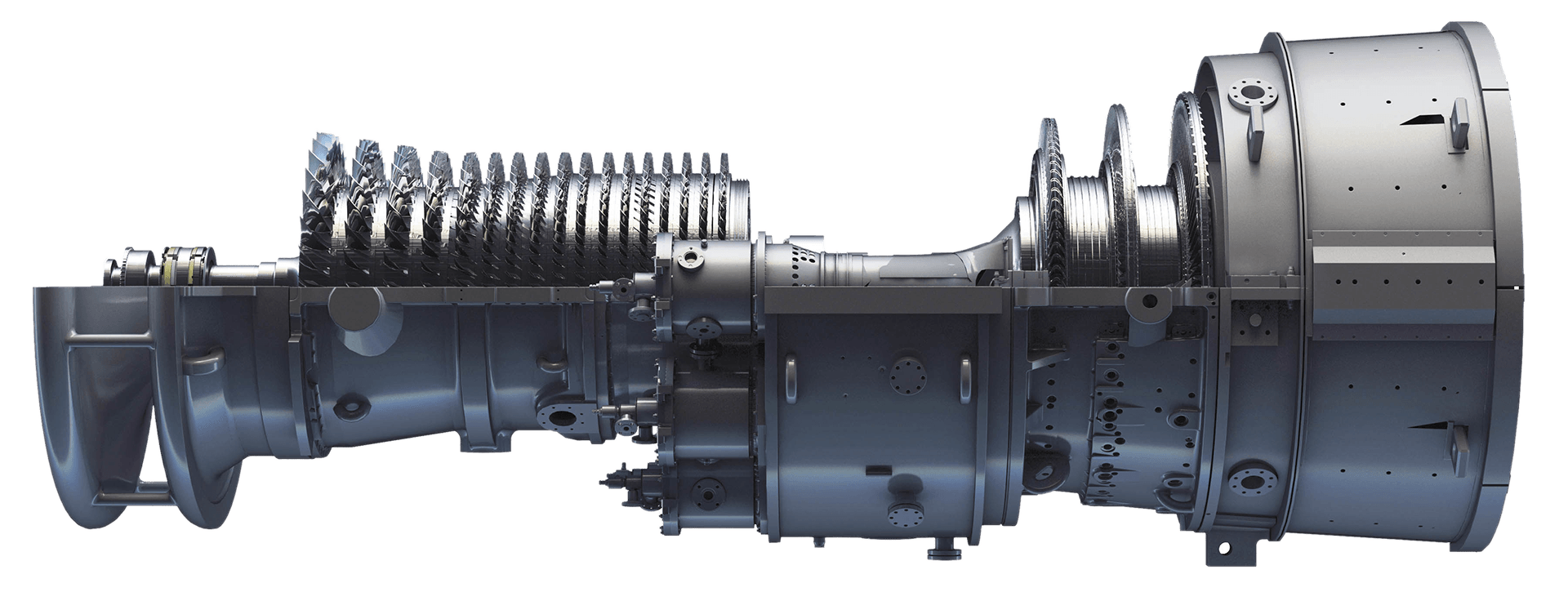

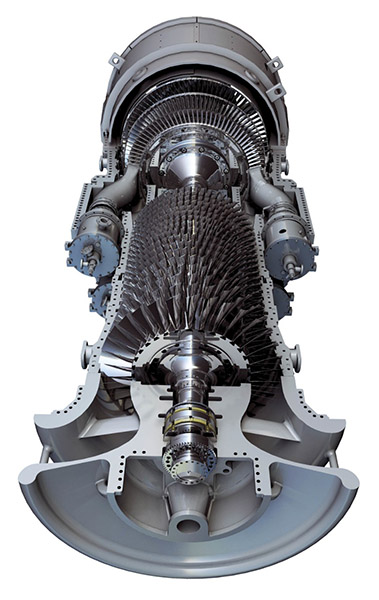

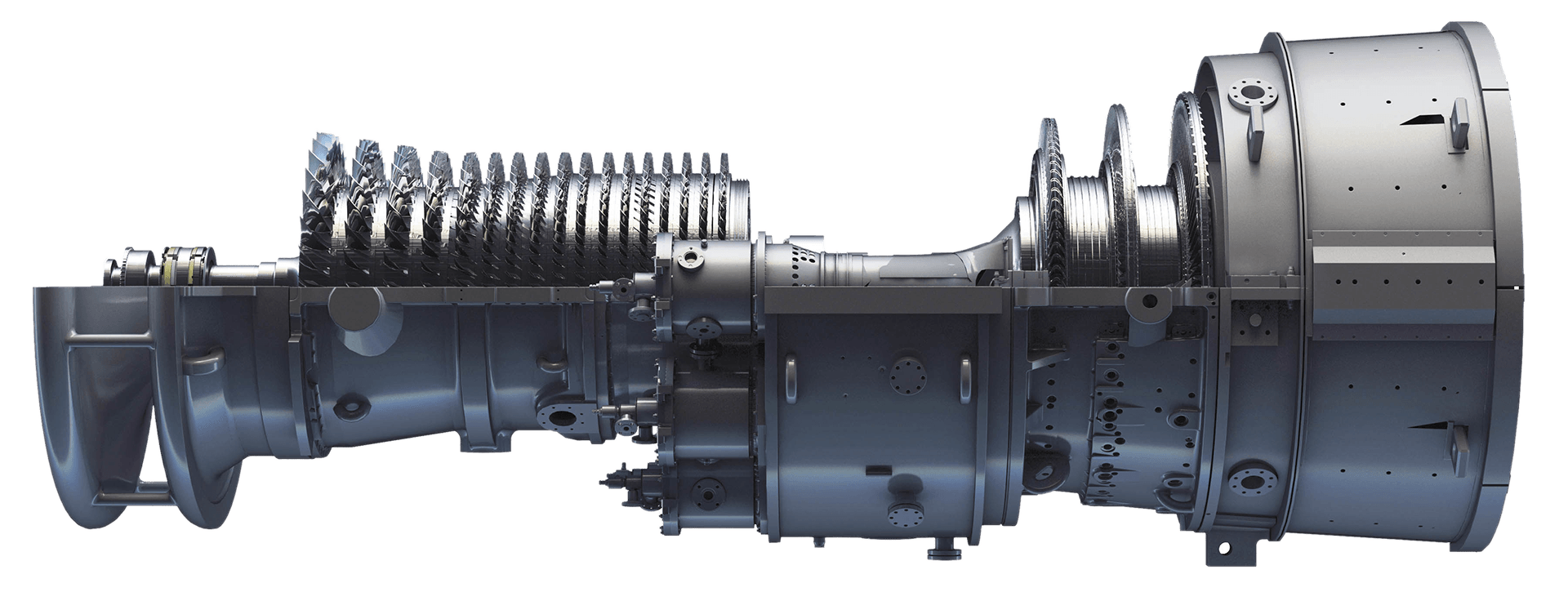

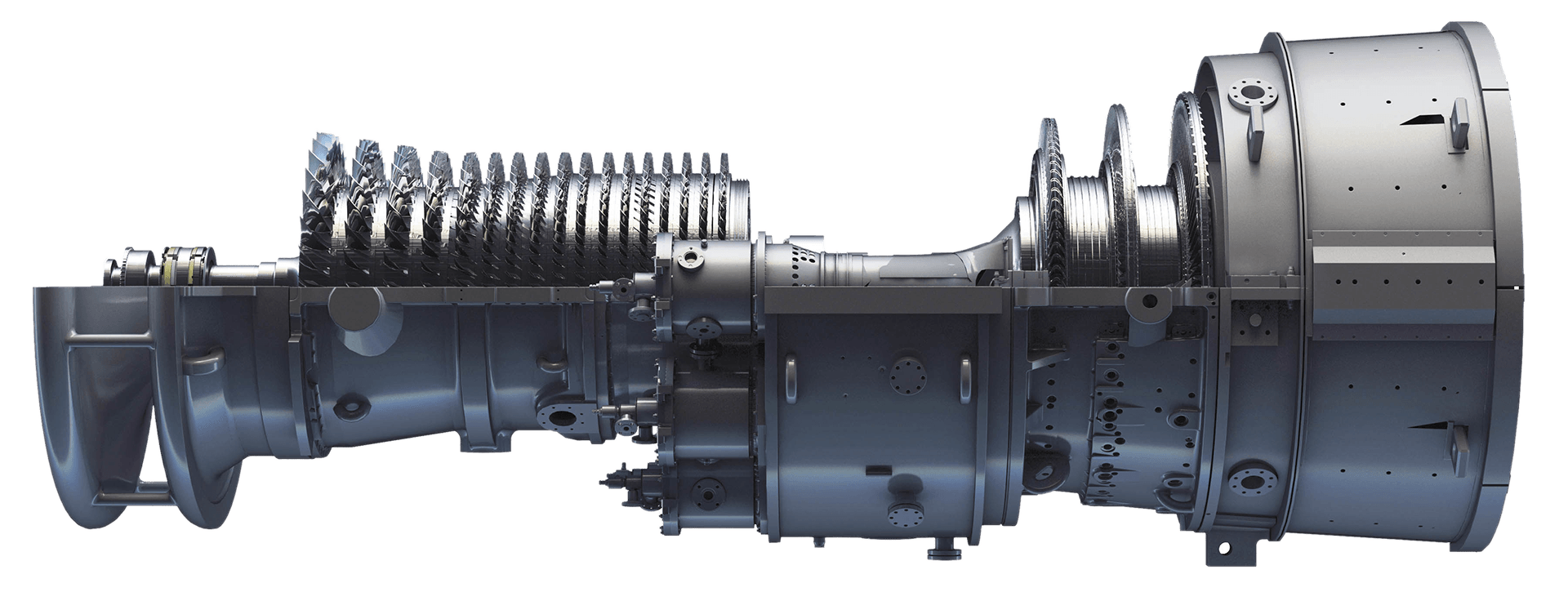

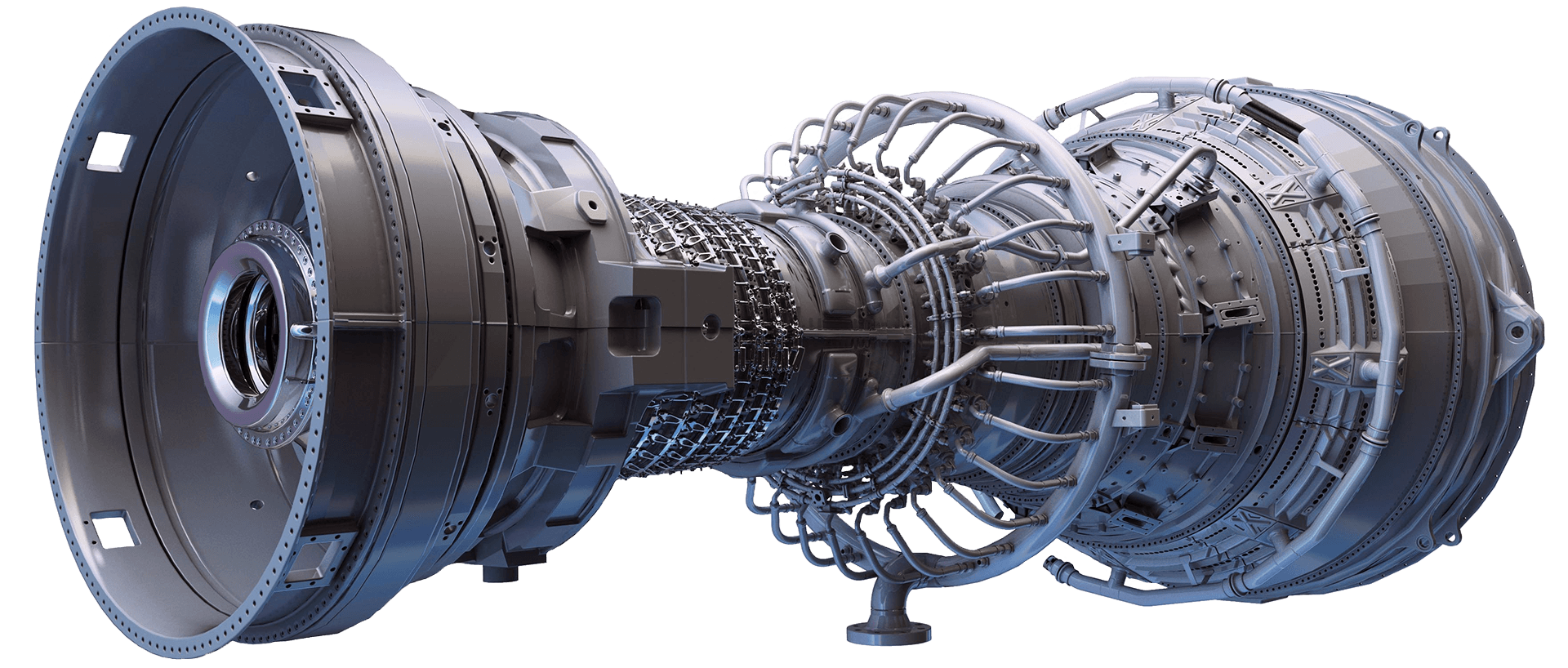

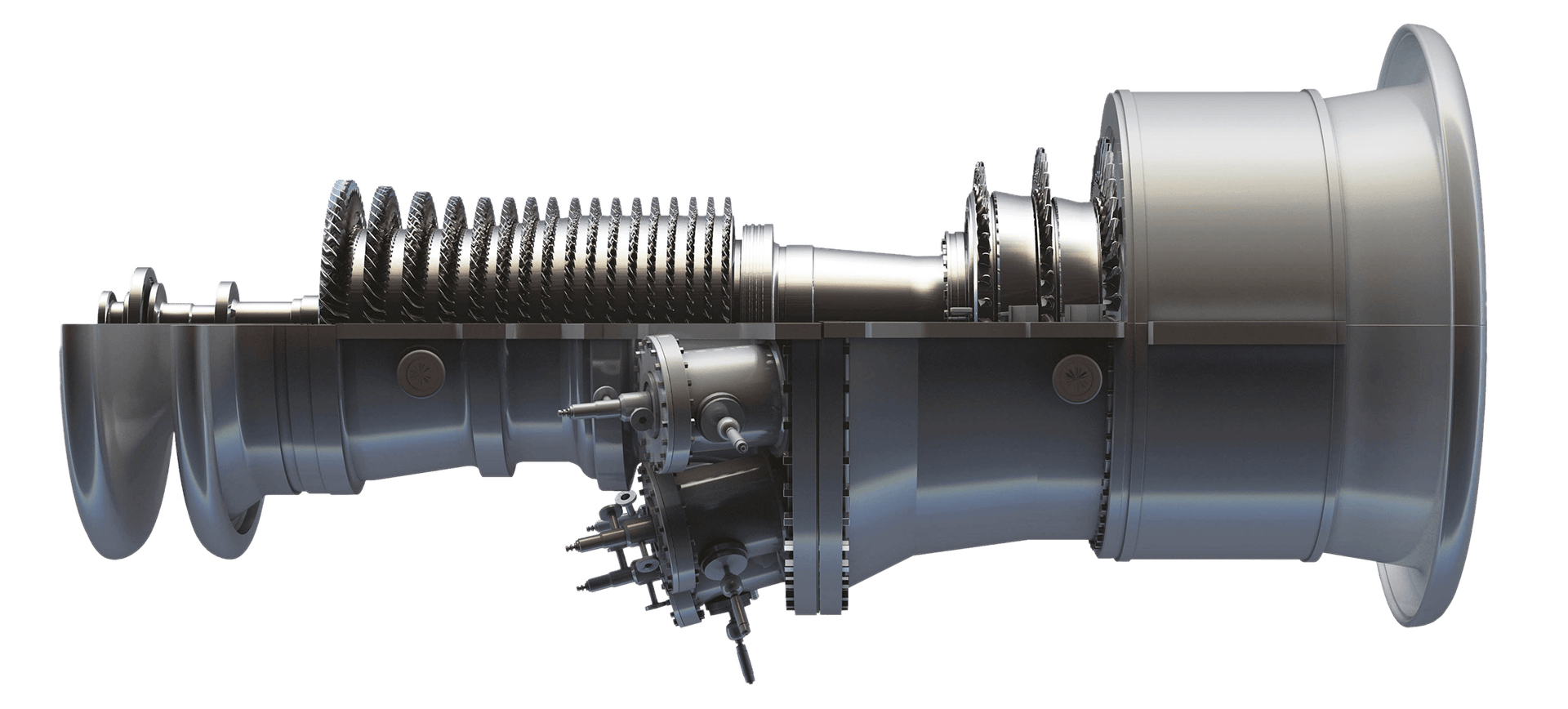

7E gas turbine

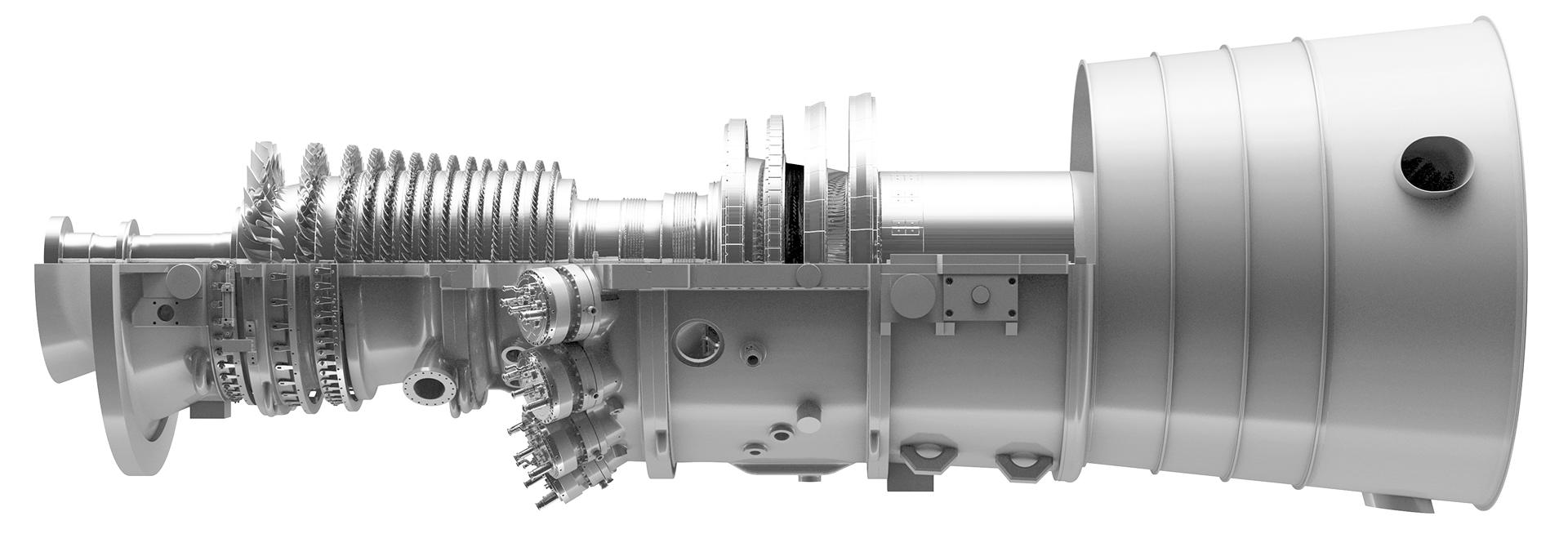

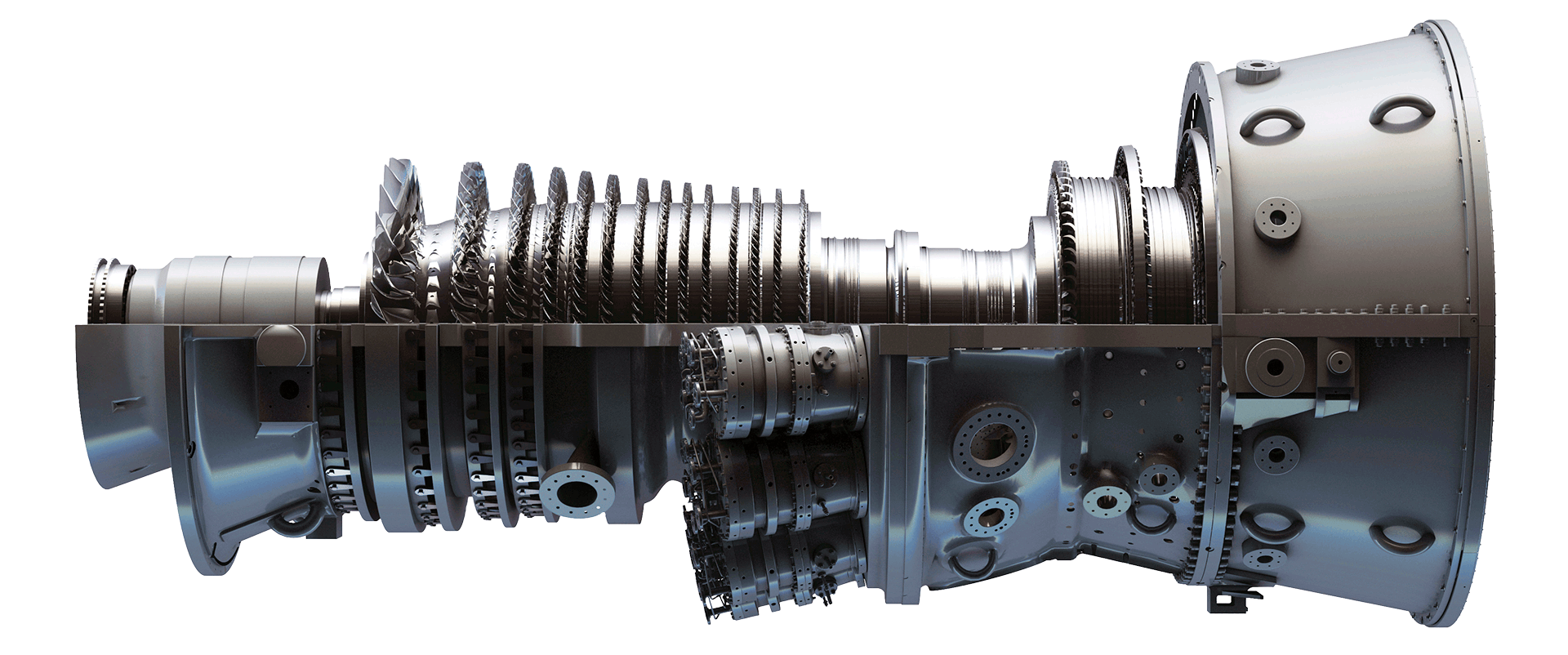

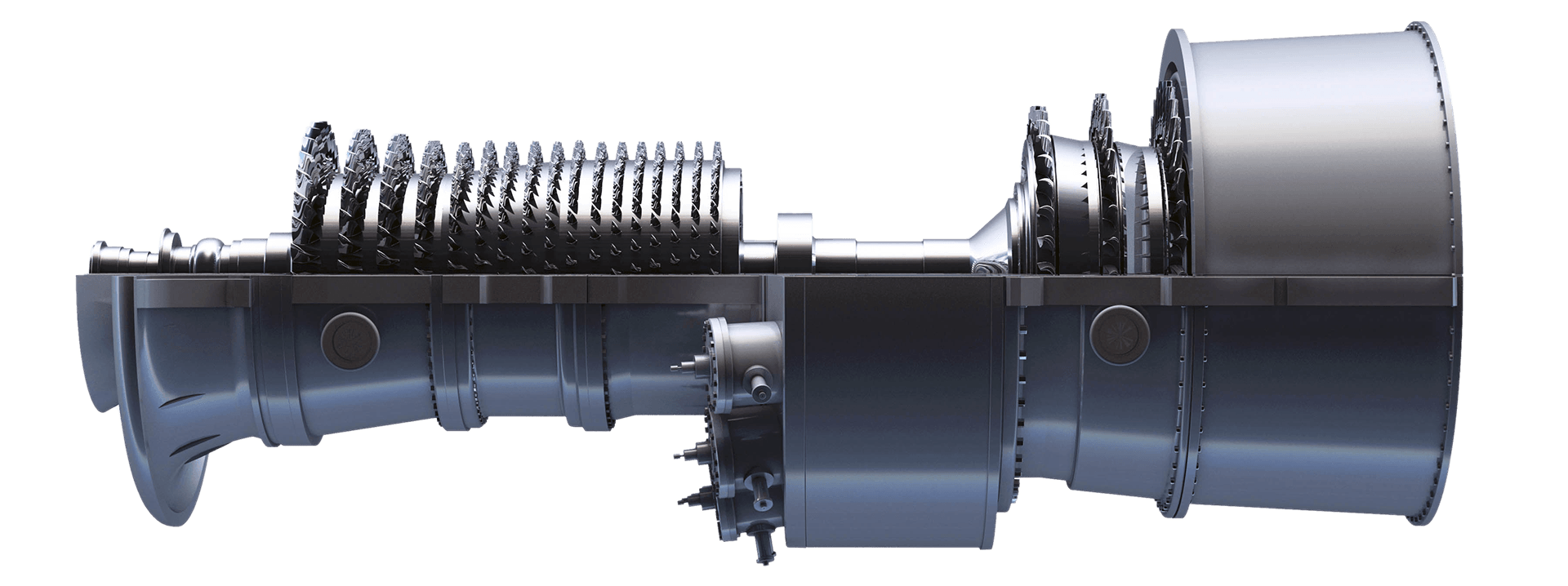

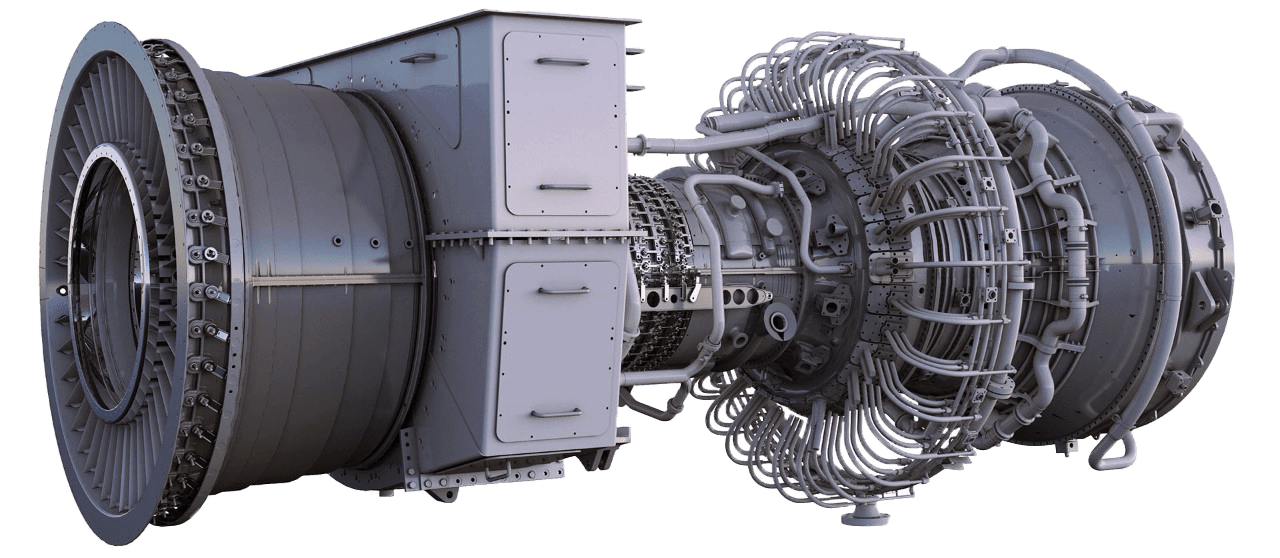

The 7E.03 gas turbine is recognized as an industry leader for 60 Hz industrial power applications. Its robust architecture and operational flexibility make it well-suited for a variety of peaking, cyclic, and baseload operations. With state-of-the-art fuel handling equipment, multi-fuel combustion system options, and advanced gas path features, the 7E gas turbine can accommodate a full range of fuel alternatives while helping to deliver better efficiency and lower emissions than other technologies in its class.

90 MW

simple cycle output

>52%

combined-cycle efficiency

<4 ppm NOx

without selective catalytic reduction (SCR)

Up to 100%

hydrogen capability

Robust architecture and operational flexibility

7E.03 gas turbine features and benefits

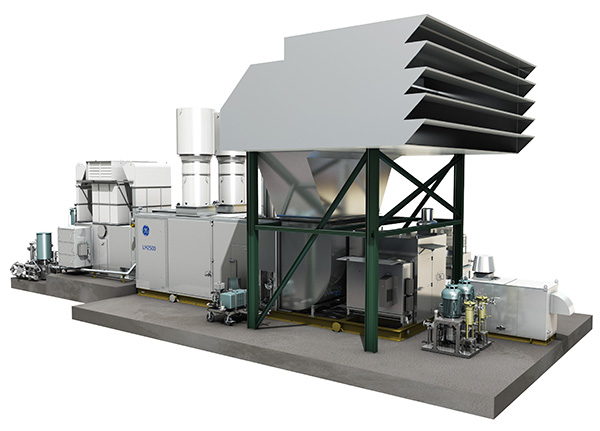

Whether providing raw horsepower to drive industrial and petrochemical processes or steady, reliable output for CHP operation, the 7E.03 gas turbine keeps your operation running.

Unmatched versatility for industrial applications

The 7E.03 gas turbine is a 60 Hz industry leader, including LNG and cogen applications, providing customers with enhanced steam/power balance.

GE Vernova's 7E: A proven performer

The 7E is as powerful as it is flexible: its fast-start, fast-load time capability may deliver 75% load in less than 10 minutes.

Environmental and economic benefits

The 7E.03 gas turbine accommodates a full range of fuel alternatives while helping to deliver better efficiency and lower emissions than other technologies in its class.

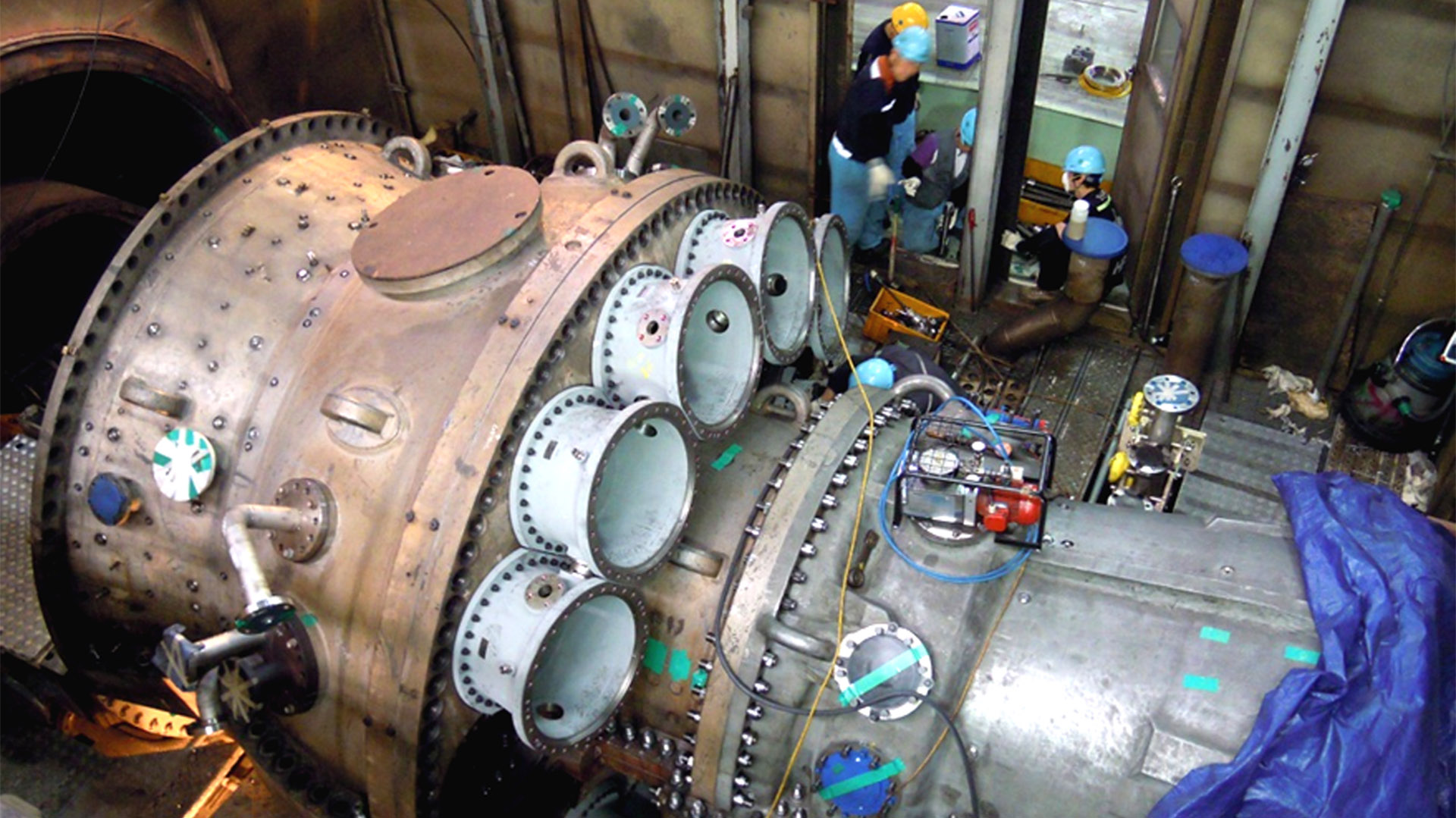

The experience that matters

The 7E gas turbine’s medium-size architecture lends itself to flexibility in plant layout and fast, low-cost additions of incremental power. The 7E features the most experience among E-class machines available today, with more than 1 million starts. 40 U.S. states have one or more installed GE Vernova 7E gas turbines, providing a total capacity of more than 40 GW.

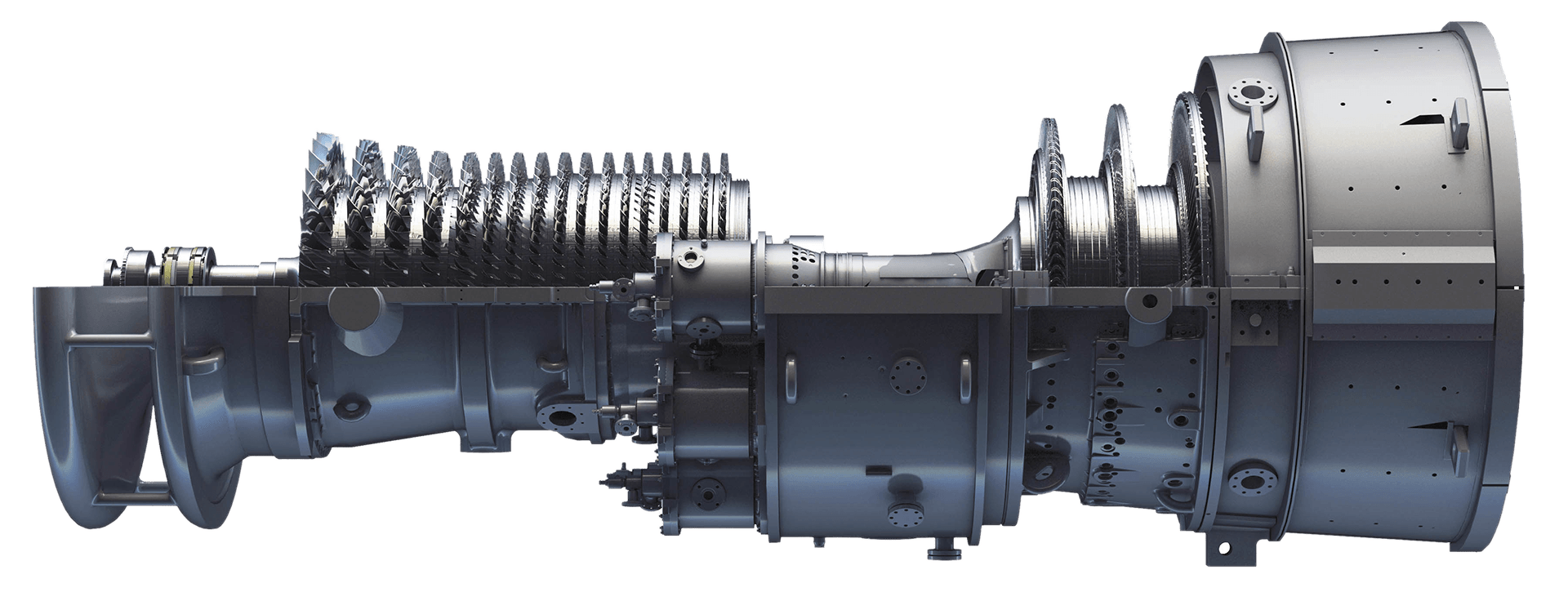

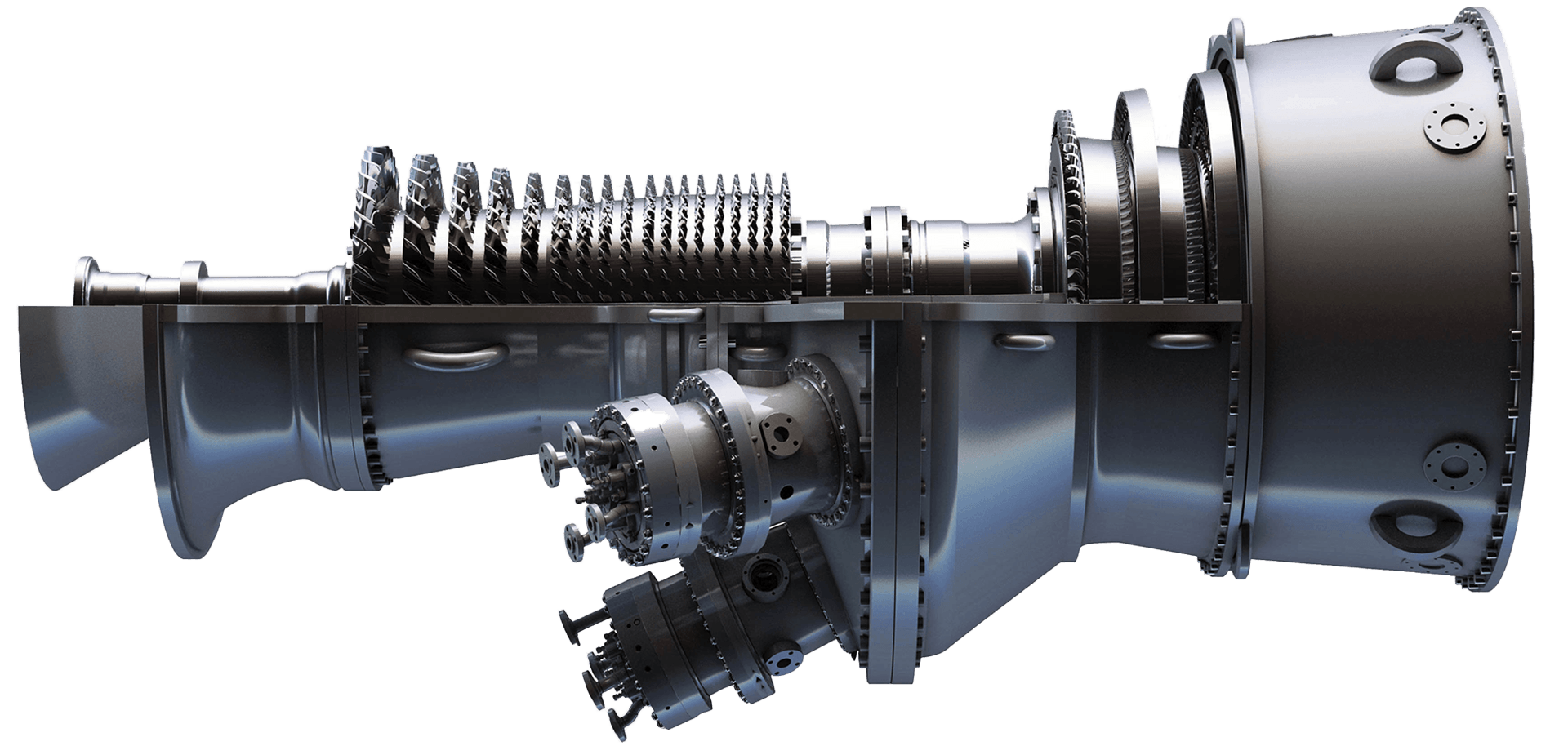

Additional features of the 7E.03 turbine

The 7E features state-of-the-art fuel handling equipment, multi-fuel combustion system options, and advanced gas path. Additionally, the 7E.03 gas turbine has an enhanced compressor with high-strength, corrosion-resistant material. Its multiple-fuel combustion system allows switching from one fuel to another while running under load, and three-stage gas turbine constructed of advanced materials improve high-temperature strength and increase inspection intervals (32,000 hours).

The exhaust energy profile and high mass flow of the 7E gas turbine can be used to enhance steam production in cogeneration applications. A tri- or dual-fuel capability for switching fuels, while running under load or during shutdown eliminates the need for water while reducing harmful emissions.

- 7Extend package: Life extension strategies

- Unlocking Technology

- Can you achieve cleaner, more flexible megawatts for your 7E?

Webinar

7Extend* package: Life extension strategies for a high-demand energy era

Join Jay Bryant as he unpacks the risk factors driving gas turbine wear, the role of refurbishment and replacement in risk mitigation, and how our 7Extend upgrade package can support cost-effective, gas turbine longevity.

Jay Bryant

7E Product Manager, GE Vernova

Webinar

Unlocking technology: How to utilize predictive and prescriptive analytics

Are you struggling with aging equipment and high maintenance costs? Discover how GE Vernova's predictive and prescriptive analytics can help reduce unplanned downtime and enhance availability, while shifting you from reactive to proactive maintenance strategies.

Tom Freeman

Chief Customer Consultant, GE Vernova

Ben Myers

Global Monitoring & Diagnostics Leader, GE Vernova

Truman Hwang

Product Manager, GE Vernova

Janet Webb

Senior Product Manager, GE Vernova

On-demand webinar and Q&A

Can you achieve cleaner, more flexible megawatts for your 7E?

As a plant manager, can you continue to reduce emissions and maintain profitability and reliability? Join our webinar with Jay Bryant to see how you can get the most out of your 7E.

Specifications

Keep your operation running

Get a look inside our 7E gas turbine with its technical specifications.

Specifications shown are 60 Hz

| 7E.03 | |

|---|---|

| Net output (MW) | 90 |

| Net heat rate (Btu/kWh, LHV) | 10107 |

| Net heat rate (kJ/kWh, LHV) | 10664 |

| Net efficiency (%, LHV) | 33.8% |

| Ramp Rate (MW/minute) | 40 |

| Startup Time (RR Hot, Minutes) | 23 |

7E series gas turbines can deliver 100% load in 10 minutes.

NOTE: All ratings are based on ISO conditions and natural gas fuel. Actual performance will vary with project-specific conditions and fuel.

Customer stories

Hear from our customers

Florida, United States

Taking the steps to reinforce renewable solar energy

74.5 MW

solar plant output

~6000 yards

area of solar farm

"Our existing solar field and gas turbines… provide a unique opportunity… to produce green hydrogen, store it onsite, and then combust it to ensure reliable service when electricity demand is high. This combination of technologies will allow gas turbines to become decarbonized, dispatchable assets that support the addition of more renewables to our grid."

Regis Repko

Senior vice president of generation and transmission strategy, Duke Energy

Customer stories

Hear from our customers

Tobago

Extending the lifetime of Tobago’s Penal Power Station

26 MW

output increase

25-30

years added to asset life

"Replacing the existing gas turbines at the Penal Power Station with GE Vernova’s upgraded units will improve our generation efficiency and add value in terms of greater availability by establishing longer intervals between scheduled maintenance outages."

Fitzroy Harewood

General Manager, PowerGen Ltd.

Customer stories

Hear from our customers

Texas, USA

7E turbines help secure future for Air Liquide’s Bayport plant

300 MW

electricity produced

1,300+ tons

steam per hour produced

"The redevelopment of our Bayport facility, which is Air Liquide’s largest industrial complex in North America, has positioned us to better serve the growing needs of our customers in this region in a safe, reliable, and efficient way."

Sue Ellerbusch

CEO of Air Liquide USA

Further reading

Learn more

7E gas turbine information

Services

Get more for your 7E gas turbine

GE Vernova's Gas Power services team stands ready to collaborate with you in providing solutions that drive your competitiveness, profitability, and productive outcomes. For every customer need, GE Vernova is ready to help with the right heavy-duty gas turbine service solution and product offerings.

Don’t see what you need? Contact us

Services

Our technologies boost reliability and flexibility, reduce the environmental footprint and cut cost of production by increasing efficiency, and the intervals between inspections.

Our technologies boost reliability and flexibility, reduce the environmental footprint and cut cost of production by increasing efficiency, and the intervals between inspections.

Upgrades

Where can our upgrades take you? Explore a world of outcomes, categorized by customer need.

Where can our upgrades take you? Explore a world of outcomes, categorized by customer need.

Maintenance and repairs

Our repairs solutions are cost-effective, properly scoped to your needs and can reduce your downtime. Our vision is to support the world’s best running fleet.

Our repairs solutions are cost-effective, properly scoped to your needs and can reduce your downtime. Our vision is to support the world’s best running fleet.

Parts

Reliable plant operations depend on access to flexible parts service. Our global distribution centers are linked to regional supply chains, meaning you’ve got access to the highest-quality component inventory.

Reliable plant operations depend on access to flexible parts service. Our global distribution centers are linked to regional supply chains, meaning you’ve got access to the highest-quality component inventory.

Multi-year agreements

By partnering with us for a long-term service agreement, you’ll be able to realize the full potential of your gas plant assets while balancing performance and risk.

By partnering with us for a long-term service agreement, you’ll be able to realize the full potential of your gas plant assets while balancing performance and risk.

Products

Find the right gas turbine to meet your needs

Whether you're generating; power for entire cities, electrifying your own operations, or are facing an emergency electricity shortage and need power fast, we can act as a versatile gas turbine supplier, ready to quickly provide a range of solutions.

- 50Hz

- 60Hz

- Simple

- 1x1CC

- 2x1CC

- All

- Heavy duty

- Aeroderivative

GE Vernova’s 9HA high efficiency, air-cooled gas turbine is one of the industry leaders among H-class offerings, and now the 9HA gas turbine is at the heart of the world's most efficient combined-cycle power plant.

| 9HA.01 | 9HA.02 | |

|---|---|---|

| Net output (MW) | ||

| Net heat rate (kJ/kWh, LHV) | ||

| Net efficiency (%, LHV) | ||

| Net heat rate (Btu/kWh, LHV) |

9HA gas turbines are 50% hydrogen (H2) capable with a technology pathway to 100%

With over 450 units deployed to more than 40 countries, GE Vernova has the largest operating and most experienced OEM F-class fleet in the world. Our 9F gas turbine delivers consistent performance and accommodates a diverse range of fuels, making it great for a variety of combined cycle and CHP applications.

| 9F.04 | |

|---|---|

| Net output (MW) | |

| Net heat rate (kJ/kWh, LHV) | |

| Net efficiency (%, LHV) | |

| Net heat rate (Btu/kWh, LHV) |

9F series turbines are GE’s most advanced F-class technology for 50 Hz applications.

GE’s 7HA high efficiency air-cooled gas turbine is one of the industry leaders among advanced class gas turbine offerings and is available in three models—the 7HA.01 at 290 MW, the 7HA.02 at 384 MW, and the 7HA.03 at 430 MW.

| 7HA.01 | 7HA.02 | 7HA.03 | |

|---|---|---|---|

| Net output (MW) | |||

| Net heat rate (kJ/kWh, LHV) | |||

| Net efficiency (%, LHV) | |||

| Net heat rate (Btu/kWh, LHV) |

7HA gas turbines are up to 50% hydrogen (H2) capable with a technology pathway to 100%

The demands of today’s power generation industry are many: low cost of electricity, dispatch volatility, along with high efficiency, reliability, and asset availability. With approximately 950 installed units producing ~175GW of power in 11 countries, GE’s 7F.04 and 7F.05 gas turbines are proven performers in all these areas.

| 7F.04 | 7F.05 | |

|---|---|---|

| Net output (MW) | ||

| Net heat rate (kJ/kWh, LHV) | ||

| Net efficiency (%, LHV) | ||

| Net heat rate (Btu/kWh, LHV) |

7F series gas turbines can balance renewables by load-following at 40 MW/min ramp rates while maintaining emissions compliance.

With unprecedented operational flexibility, robust engineering and long operation intervals, the GT13E2 can be used in many different applications—all while meeting a very broad range of environment and operating conditions.

| GT13E2-210 | |

|---|---|

| Net output (MW) | |

| Net heat rate (kJ/kWh, LHV) | |

| Net efficiency (%, LHV) | |

| Net heat rate (Btu/kWh, LHV) |

GT13e2 gas turbines can run on up to 30% hydrogen fuel.

Formerly known as the Frame 9E, GE Vernova’s 9E gas turbine can help decrease costs and increase revenue for your plant. From the desert to the tropics to the arctic, the rugged 9E.03 heavy-duty gas turbine provides essential power and performs in a vast number of duty cycles and applications. The 9E.04 gas turbine provides increased power and performance while maintaining the simplicity and operational strengths of the 9E.03.

| 9E.03 | 9E.04 | |

|---|---|---|

| Net output (MW) | ||

| Net heat rate (kJ/kWh, LHV) | ||

| Net efficiency (%, LHV) | ||

| Net heat rate (Btu/kWh, LHV) |

9E series gas turbines can run on 52 types of fuel.

A single, economical solution for the dispatch needs of nearly every industry condition.

| LMS100 PA+ | LMS100 PB+ | |

|---|---|---|

| Net output (MW) | ||

| Net heat rate (kJ/kWh, LHV) | ||

| Net efficiency (%, LHV) | ||

| Net heat rate (Btu/kWh, LHV) |

LMS100 gas turbines can start up in 8 minutes

The 7E.03 gas turbine is recognized as an industry leader for 60 Hz industrial power applications. Its robust architecture and operational flexibility make it well-suited for a variety of peaking, cyclic, and baseload operations. With state-of-the-art fuel handling equipment, multi-fuel combustion system options, and advanced gas path features, the 7E gas turbine can accommodate a full range of fuel alternatives while helping to deliver better efficiency and lower emissions than other technologies in its class.

| 7E.03 | |

|---|---|

| Net output (MW) | |

| Net heat rate (kJ/kWh, LHV) | |

| Net efficiency (%, LHV) | |

| Net heat rate (Btu/kWh, LHV) |

7E series gas turbines can deliver 100% load in 10 minutes.

GE Vernova’s 6F gas turbine offers the superior performance, reliability, and flexibility typically associated with larger power plants. Our 6F gas turbine packs big power into a small package, offering durability and flexibility for harsh, remote, or floating power environments. Whether it be for 50 or 60 Hz, the 6F gas turbine can maintain enhanced output and exhaust energy for combined cycle and CHP performance. The 6F offers segment-leading 32,000-hour combustion and hot gas path inspection intervals.

| 6F | |

|---|---|

| Net output (MW) | |

| Net heat rate (kJ/kWh, LHV) | |

| Net efficiency (%, LHV) | |

| Net heat rate (Btu/kWh, LHV) |

6F gas turbines offer fuel flexibility and hydrogen capability while maintaining the reliability you’ve come to depend on

A leader in the +40 MW space, the LM6000 has over 40 million operating hours and more than 1,300 units shipped.

| LM6000 PC Sprint | LM6000 PF+ Sprint | |

|---|---|---|

| Net output (MW) | ||

| Net heat rate (kJ/kWh, LHV) | ||

| Net efficiency (%, LHV) | ||

| Net heat rate (Btu/kWh, LHV) |

LM6000 gas turbines can start up in 5 minutes

Its ability to operate in island mode, coupled with multiple decades of proven rugged performance, make the 6B an excellent solution for remote installations and extreme operating conditions. The rugged, reliable 6B heavy-duty gas turbine is a popular choice for refineries, natural gas liquefaction power, CHP applications, and industrial power.

| 6B | |

|---|---|

| Net output (MW) | |

| Net heat rate (kJ/kWh, LHV) | |

| Net efficiency (%, LHV) | |

| Net heat rate (Btu/kWh, LHV) |

6B gas turbines can operate on a wide range of non-standard gas or liquid fuels, including over 90% hydrogen

The LM2500 family of aeroderivative gas turbines boasts several times the operating experience of its competitors combined, and its flexibility and reliability are unsurpassed.

| LM2500XPRESS+G4 DLE UPT | LM2500XPRESS+G5 DLE UPT (25ppm NOx) | |

|---|---|---|

| Net output (MW) | ||

| Net heat rate (kJ/kWh, LHV) | ||

| Net efficiency (%, LHV) | ||

| Net heat rate (Btu/kWh, LHV) |

LM2500 gas turbines feature >99.8% availability

Introducing one of the world’s most modular, reliable, and experienced mobile gas turbines.

| TM2500 SAC | TM2500 DLE | |

|---|---|---|

| Net output (MW) | ||

| Net heat rate (kJ/kWh, LHV) | ||

| Net efficiency (%, LHV) | ||

| Net heat rate (Btu/kWh, LHV) |

TM2500 gas turbines can be installed and commissioned in 11 days

Former names of GE Vernova 7E gas turbines: Frame 7E, 7E, 7EA, 7E 3-Series, 7111(EA), 7121(EA), PG7111EA, PG7121EA, 7EA PIP, and MS7001(EA)

*Trademark of GE Vernova and/or its affiliates.

Gas Power

Gas Power engineers cleaner, more accessible energy that communities depend on to power growth and prosperity.

Contact usDecarbonization - the future of energy

See how Gas Power is helping to build a world that works.

Learn more