The world's most efficient heavy-duty gas turbine

Generating more reliable, cost-effective power for Vietnam

With a strong local presence and a commitment to helping grow Vietnam’s economy with the latest energy-efficient technologies, GE has gas turbine solutions to help Vietnam meet current energy needs while providing a path to continued regional growth.

Gas turbine technology can provide energy security through the production of reliable, flexible and sustainable energy that supports and complements renewable energy sources. This is known as “grid firming.”

Our HA gas turbine fleet has the lowest cost conversion of fuel to power, which translates to more power at a lower cost, lower maintenance needs, and reduced CO2 emissions—all good news for Vietnam’s energy producers and consumers looking to spend less on electricity.

Grid firming or grid balancing (also known as capacity firming or renewable firming) is the addition of another energy resource to a renewable power plant to provide secure, stable power any time the sun isn’t shining or the wind isn’t blowing. Grid firming is vital for any power generation network, especially one like Vietnam’s, with a high percentage of renewable power sources.

Born from aviation technology, GE’s aeroderivative portfolio features highly flexible and mobile technologies for use in a wide variety of applications, including utility generation, district heating, mobile power, fast power, and of course, grid stability. GE’s aeroderivative gas turbines have a wide range of characteristics that makes them exceedingly suitable for capacity firming.

The LM2500XPRESS can run on 35% hydrogen, and when an SCR is added to the unit to reduce emissions even further, NOx can be reduced to 2.5 ppm and CO to 4ppm.

The LM6000 offers 99%+ reliability and 98% availability. It can start up in 5 minutes, and its dual-fuel capabilities provides fuel flexibility and helps customers meet emissions limits.

The highly efficient, air-cooled 9HA gas turbine is an industry leader in the H-class space, delivering exceptionally low lifecycle costs per megawatt to Vietnam.

Cost-efficient conversion of fuel to electricity

Our H-class gas turbines enable the most cost-effective conversion of fuel to electricity to help Vietnamese utilities meet increasing power demands while saving operating costs and meeting local emissions requirements.

Our HA gas turbines have earned two world records for efficiency—one for powering the world’s most efficient combined-cycle power plant for EDF in Bouchain, France (achieving 62.2% efficiency on a net combined-cycle basis on a 50 Hz grid), and a second world record for achieving 63.08% gross efficiency on a 60 Hz grid at the Nishi-Nagoya Power Station in Japan.

Operational flexibility

Our 9HA.02 gas turbine features a fast, 30-minute ramp-up from start command to full load, and up to 88 MW/minute ramping capability in a 1x1 configuration or 176 MW/minute in a 2x1 multi-shaft configuration.

The 9HA.02 also offers both standby and response modes to deliver emission-compliant operation at load levels of minimum fuel consumption. This feature complements plant turndown capability of 33% of full-load output. These units are also fuel flexible, with the ability to accommodate gas and liquid fuels with wide gas variability, including high ethane (shale) gas, hydrogen-blending, low-and-medium BTU gas and liquefied natural gas.

Tried and tested gas turbines

Installing a gas turbine in your plant shouldn’t involve any unknowns. Across our HA fleet, each original turbine is put through a rigorous full-speed, full-load (FSFL) validation test at our Greenville, South Carolina facility.

This $200 million investment allows us to push the units beyond real-world conditions—running the turbines at 110% of their rated speeds at load, and replicating the harshest conditions, from the Arabian Desert to the mountains of Colorado—all to ensure that our customers have security of supply for their end users.

Faster installation reduces time and cost

GE’s HA gas turbine auxiliary systems are pre-configured, factory-assembled and tested modules engineered to reduce field connections, piping, and valves.

This translates to a simpler, faster installation that requires less labor and reduces field schedule and installation quality risks while improving overall installation times—up to 25% quicker compared to GE F-class gas turbine enclosures. This modular configuration also makes it easier for technicians to perform any needed maintenance over the gas turbine’s lifecycle.

Recognized for leading in industry excellence

GE is the only original equipment manufacturer (OEM) that has been previously recognized by a 3rd party for setting two world records for powering the most efficient plant in an H-class combined-cycle (CC) application: 63.08% gross CC efficiency at Chubu Electric’s Nishi Nagoya power plant in Japan (7HA, 60Hz), and 62.22% net CC efficiency at EDF’s Bouchain power plant in France (9HA, 50Hz).

In 2021, Southern Power Generation’s 1.4 GW Track 4A power plant, a natural gas-fired power plant in southern Malaysia—equipped with the first commercial GE 9HA.02 gas turbines—was recognized by POWER Magazine as their “2021 Power Plant of the Year” and by Diesel & Gas Turbine WORLDWIDE as “Power Plant of the World”, a meaningful model for balancing climate awareness, energy affordability, and reliability.

In addition, GE’s HA technology was adopted at China Huadian Corp’s Juliangcheng plant to help accelerate the retirement of existing coal-fired capacity and replace it with new, highly efficient combined-cycle gas turbines—an important role that earned POWER Magazine’s “ReinventionAward”.

Proven technology throughout the world

GE introduced H-class technology to the industry 26 years ago. Today, GE’s HA product portfolio—first introduced in 2014—was engineered to reduce carbon emissions and to help support today’s flexible power generation model. The H-class portfolio leverages GE’s advanced combustion and compressor technology along with critical advancements in material science, design and coatings for higher output and performance.

GE’s HA portfolio is the world’s fastest-growing fleet in its class with more than 129 gas turbines ordered by 50+ customers across 20 countries. Our HA technology has accumulated more than 1M operating hours (as of August 2021) at 30 customer sites globally, and 2/3rd of our HA operating fleet has 16K+ operating hours and it is ready to help tackle Vietnam's power needs.

Powering Vietnam towards decarbonization with the lowest emissions in the industry

The 9HA’s DLN 2.6e combustion system offers a step change in performance, emissions, and fuel flexibility. The DLN 2.6e maintains many of the elements of GE’s DLN 2.6+ combustion system and introduces advanced premixing for reduced NOx emissions while enabling high plant efficiency.

Its advanced premixer enables expanded fuel flexibility to operate on both “rich” and “lean” gaseous fuels, a 50% hydrogen (H2) capability with a future technology pathway to 100%, a gas turbine turndown to more than 30% load, and an optional park mode at 7-15% load, further reducing customers’ operating costs.

Vietnam has come a long way since the 80s and 90s when the country would experience severe electricity shortages. Today, with an electrification rate of 100%, the power capacity of Vietnam's electrical system has reached 77600 MW, ranking first in the Southeast Asia region. The transition from coal-to-gas, as outlined in the Power Development Plan 8, will be key to enabling the growth of renewables and addressing the energy trilemma of reliability, affordability, and sustainability.

Interested in learning more about how GE is helping support Vietnam’s growth? Our articles and case studies provides additional information, insights and stories from GE experts in the region. Stay tuned for more to come!

GE is committed to fueling Vietnam’s growth through development of local talent in high value sectors like engineering, and we work with local SMEs and suppliers. Our technologies support Vietnam’s diverse energy mix by providing more reliable and flexible power. But we’re not only focused on gas turbines: Today, our solutions also include plant-wide offerings such as steam turbines, generators and HRSGs.

To help ensure efficient and reliable power for Thailand, EGAT has partnered with GE to build the country’s first power plant featuring a GE’s 9HA.02 gas turbine. The Bang Pakong plant is expected to generate 1.4 GW of power; equivalent to powering ~3M homes in the region.

Advanced manufacturing and repair technology R&D Center in Singapore to develop next-generation repair capabilities for GE HA gas turbines

GE’s gas turbine validation facility in Greenville, South Carolina (USA)

With local repair capabilities and the strength of our global expertise, GE is the service provider of choice in Asia, where we have 90% in-region self-sufficiency for heavy duty gas turbines—including the HA.

Located in Jurong, Singapore, the GRSS is the first HA-class repair development center outside the U., allowing GE to better serve customers in Asia and other countries around the world.

GE’s HA gas turbine technology is the technology of choice for the region’s power providers, and GE already has a strong footprint in the ASEAN region, with 5 9HA.02 projects—for a total of 10 9HA.02 gas turbines—currently under construction. Learn more about these projects.

MALAYSIA - Track 4 (Sultan Ibrahim Power Plant), Pasir Gudang (Johor Malaysia)

MALAYSIA - Track 4B, Alor Gajah (Melaka)

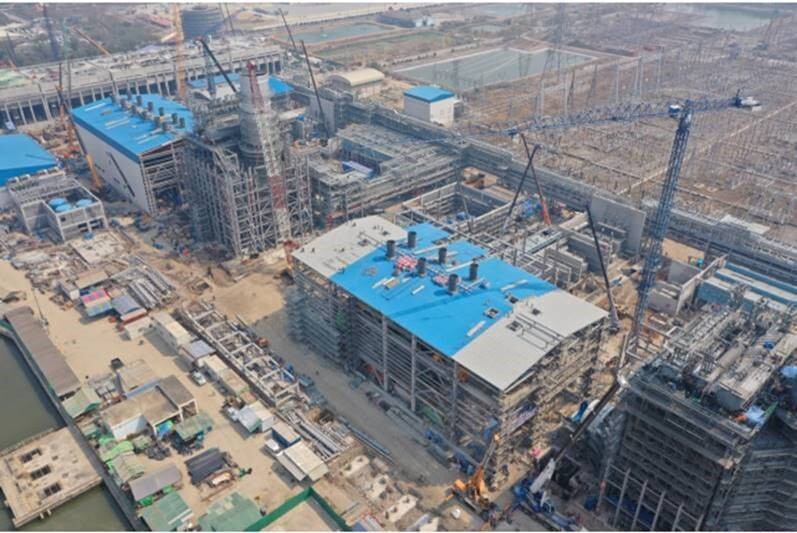

INDONESIA - Tambak Lorok (Semarang, Central Java)

INDONESIA - Jawa One (Cilamaya)

THAILAND - EGAT Bangpakong (Bangkok)

MALAYSIA - Track 4 (Sultan Ibrahim Power Plant), Pasir Gudang (Johor Malaysia)

MALAYSIA - Track 4B, Alor Gajah (Melaka)

INDONESIA - Tambak Lorok (Semarang, Central Java)

INDONESIA - Jawa One (Cilamaya)

THAILAND - EGAT Bangpakong (Bangkok)

Owned by Southern Power Generation Sdn Bhd., this 1440 MW combined-cycle power plant began operations early 2021 and is home to Malaysia’s first GE 9HA.02 gas turbines. The heart of the plant will be two generating blocks, each equipped with a 9HA.02 gas turbine, generator and heat recovery steam generator. Overall plant performance will be monitored and enhanced with GE’s Predix* asset performance management (APM) software and Fleet360* platform of gas plant solutions.

Owned by Edra Power, this 2,242 MW combined-cycle power plant is due to begin operations in 2021 and will be the country’s largest combined-cycle gas turbine power plant. Powered by 3 of GE’s 9HA.02 gas turbines, it is capable of providing up to 10% of Malaysia’s electricity needs.

An initiative under the government’s plans of achieving 35,000 MW capacity, the 780 MW combined-cycle Tambak Lorok power plant will house Indonesia’s first 9HA gas turbine—as well as a GE generator, D650 steam turbine, heat recovery steam generator (HRSG) and balance of plant equipment. Expected to begin operations in 2021, the plant will provide enough power to supply the equivalent of up to 5 million homes and help ensure more reliable and affordable electricity for the Java-Bali grid.

Part of the Indonesian government’s 35 GW electrification initiative to power close to 11 million homes throughout the country, the 1750 MW Jawa One combined-cycle power plant is due to begin operations in 2021 and will be powered by two units of GE’s 571 MW 9HA.02 gas turbines and two units of the 309 MW D652 steam turbine. The plant will also be serviced by GE as part of a 25+ multi-year agreement that includes APM digital solutions, commissioning and installation, parts, field and repair services.

Thailand's largest gas-fired power plant, this 1,400 MW combined-cycle facility is owned and operated by the Electricity Generating Authority of Thailand and will be equipped with 2 of GE's 9HA gas turbine. Currently planned for completion in 2020, the plant is expected to deliver more than 1,400 MW to the national grid – enough electricity to supply the equivalent of up to 2 million average Thai homes and will help Thailand achieve its goal of securing 57,460 MW of power generation capacity by 2036.