Balancing the grid

GE Power Taiwan LTD, a partnership based on trust

GE is playing a key role in helping Taiwan achieve its energy goals and is committed to working closely with local partners like Taiwan Power Company (TPC). GE’s relationship with TPC dates back to 2016, when the leading electricity provider awarded GE its first major project in Taiwan for the Datan 7 plant in Taoyuan. In 2019, TPC selected GE’s latest HA technology for its new Datan 8 & 9 combined-cycle power plant, and the most recent Hsinta and Taichung projects will be GE’s fourth HA gas turbine project in Taiwan. Learn more about how GE is helping balance Taiwan’s electricity grid and meet future demand.

Grid firming

Maintaining a stable power supply for Taiwan

The Taiwan government has a target of 20% renewables in the energy mix by 2025, and 25% by 2030. To achieve these targets, Taiwan needs the addition of another energy source to provide secure and stable power supply at any time, particularly when the sun isn’t shining or the wind isn’t blowing.

How does gas help provide a more stable grid?

Grid firming—also known as nameplate capacity firming, capacity firming, or renewable firming—is widely used to keep the grid stable in the face of potential wind, solar, and hydro intermittency. Gas-fired power plants are available regardless of the time of day or weather conditions, providing dependable capacity as long as needed—minutes, hours, days or weeks at a time. If gaps arise in renewable energy supply, an ancillary resource like a GE gas turbine fills those gaps and helps maintain grid stability.

The latest technology

Best in class gas turbines for Taiwan

GE introduced H-class technology to the industry 26 years ago. Today, GE’s HA product portfolio is engineered to reduce carbon emissions and help support today’s flexible power generation needs. Our HA gas turbine fleet is the latest evolution of our proven 7F technology, and it features the lowest cost conversion of fuel to power—which translates to more power at a lower cost. In fact, based on our many commissioned projects around the world, the 7HA gas turbine can deliver the lowest cost per kWh as compared to other gas turbine technologies.

If you’re looking to add smaller blocks of power to existing plants, GE’s aeroderivative gas turbines are a fast, cost-effective solution. With more than 100 million total operating hours, our aeroderivative gas turbines offer flexible and reliable power with engineering expertise from aviation engines.

- 7HA.03 gas turbine

- Aero gas turbines

Cost-effective, proven technology

7HA.03 gas turbine

The 7HA.03 is the most efficient 60Hz gas turbine in the world. This latest technology features more than 64% combined-cycle efficiency, higher than any other competing technology available today.

With the 7HA gas turbine fleet, you will benefit from:

- Longstanding presence in Taiwan

- Proven technology, global experience

- Industry–leading reliability and availability

- Operational flexibility–operating with natural gas or liquids

- Higher combined–cycle efficiency

- 430 MW of additional power

- Fast ramp rate–75 MW/min.

- Ease of maintenance

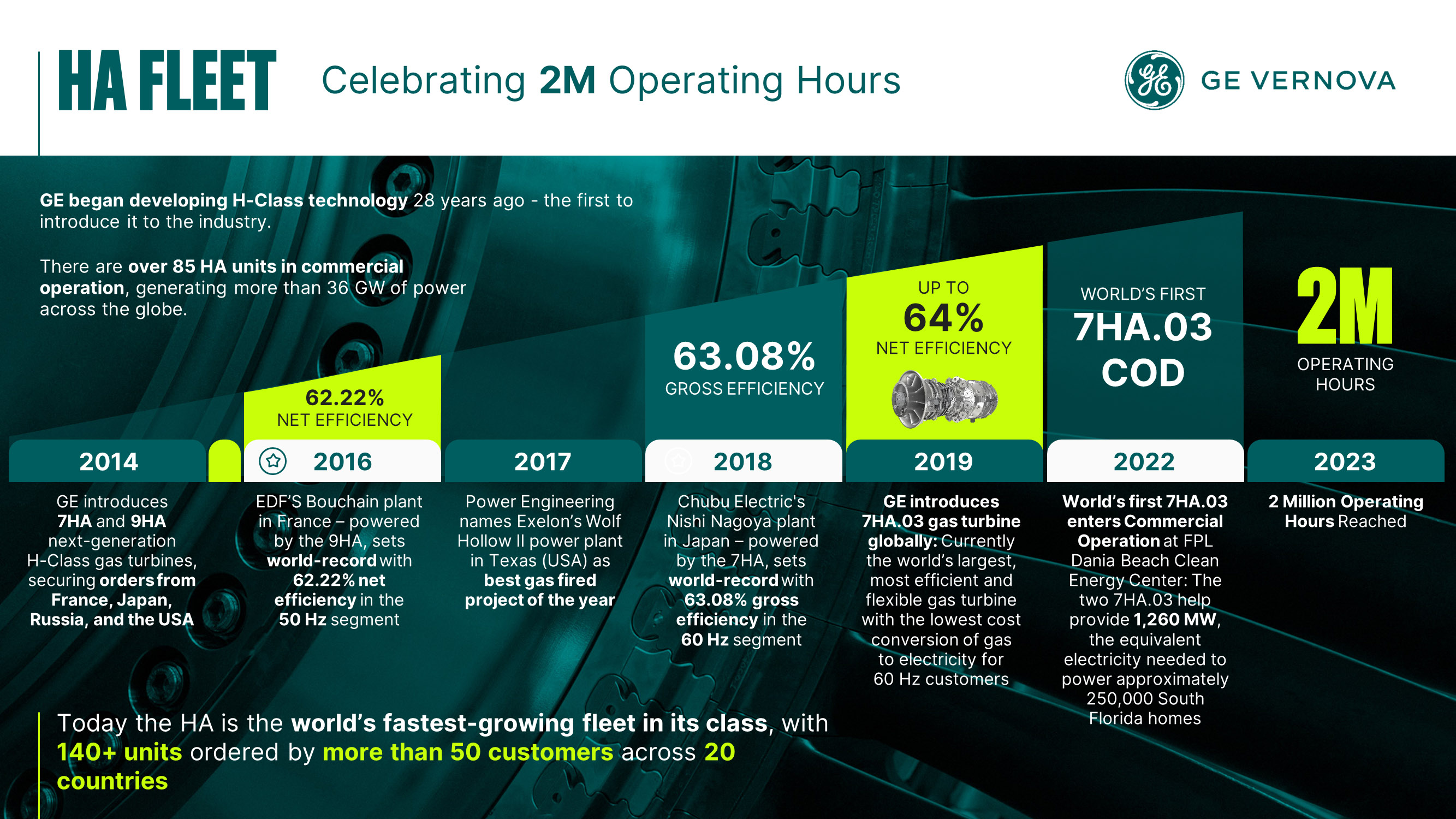

A leader in H-class technology

Proven technology and combined-cycle efficiency

The highly efficient, air-cooled 7HA gas turbine is an industry leader in the H-class space, delivering exceptionally low lifecycle costs per megawatt.

Proven technology

Field and test cell validated

Installing a gas turbine in your plant shouldn’t involve any risks. Across our HA fleet, each original turbine is put through a rigorous full-speed, full-load (FSFL) validation test at our Greenville, South Carolina facility. This $200 million investment allows us to push the units beyond real-world conditions—running the turbines at 110% of their rated speeds at load, and replicating the harshest conditions, from the Arabian desert to the mountains of Colorado—all to help ensure that our customers have security of supply for their end users.

Combined-cycle efficiency

Cost-efficient conversion of fuel to electricity

Our H-class gas turbines enable the most cost-effective conversion of fuel to electricity to help utilities meet increasing power demands while saving fuel and operating costs and meeting local emissions requirements. Our HA gas turbines have earned two world records for efficiency—one for powering the world’s most efficient combined-cycle power plant for EDF in Bouchain, France (achieving 62.22% efficiency on a net combined-cycle basis on a 50 Hz grid), and a second world record for achieving 63.08% gross efficiency on a 60 Hz grid at the Nishi-Nagoya Power Station in Japan.

Global and local experience

A powerful installed base

GE introduced the first H-class gas turbine 18 years ago, and since then our engineering teams have been making continuous performance enhancements. Now GE’s fastest-growing gas turbines in its class, our HA fleet of 44 commercial units has accumulated more than 650,000 operating hours. In total, more than 45 customers have ordered more than 100 gas turbines. Learn more about the benefits of the HA gas turbine fleet.

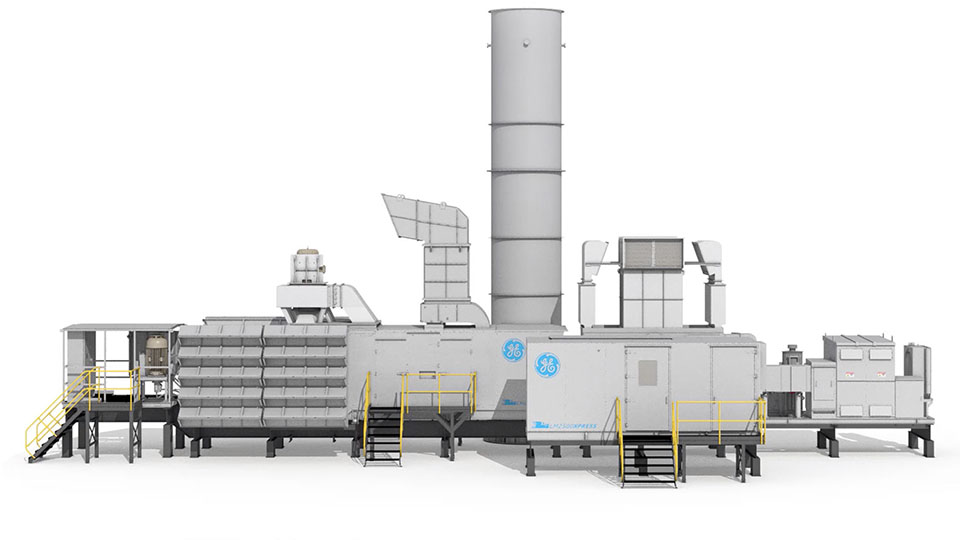

Simplified modular construction

Faster installation reduces time and cost

GE’s HA gas turbine auxiliary systems are pre-configured, factory-assembled and tested modules engineered to reduce field connections, piping, and valves. This translates to a simpler, faster installation that requires less labor and reduces field schedule and installation quality risks while improving overall installation times—up to 25% quicker compared to GE F-class gas turbine enclosures. This modular configuration also makes it easier for technicians to perform any needed maintenance over the gas turbine’s lifecycle.

The aero advantage

LM2500XPRESS* and TM2500*

Born from aviation technology 40 years ago, our aeroderivative portfolio features highly flexible and mobile technologies for a wide variety of applications, including utility generation, marine propulsion, district heating, grid stability, and mobile power. GE has an installed base of >1,400 aeroderivative gas turbines deployed in >60 countries representing more than 59 GW of installed capacity, with a total of >150M operating hours. GE’s LM2500XPRESS aero gas turbine is already the gas turbine of choice for TPC, which recently ordered six LM2500XPRESS gas turbines for its Tung Hsiao Power Plant Renewal Project.

GE recently announced selective catalytic reduction (SCR) upgrades—a post combustion process that effectively reduces the nitrogen oxide (NOx) emissions produced by lean-burn diesel or gas engines—for the TM2500 and LM2500XPRESS, aeroderivative gas turbines.

LM2500XPRESS gas turbine

The LM2500XPRESS aeroderivative gas turbine is 95% factory assembled into simplified modules for fast and easy site installation and has an 80% reduction in electrical interconnects compared to traditional plants. For customers who need power in days, the LM2500EXPRESS can be installed in as little as 2 weeks with a minimal crew. Its plug and play nature enables flexible power where it is needed quickly and efficiently.

TM2500 gas turbine

With more than 20 years of experience and over 300 units installed around the world, the TM2500 is a proven solution for providing a baseload bridge to permanent power installations or for generating backup power in the wake of natural disasters, plant shutdowns, grid instability or isolated locations. Get the power you need—fast—with GE's TM2500 mobile aeroderivative gas turbine generator set.

Webinars

Hear from our experts

- HA technology

- The race to net zero

Local presence

GE in Taiwan, by the numbers

GE has been playing an important role in supporting the development of Taiwan since 1961. Today, GE in Taiwan’s energy and aviation sectors has over 200 staffers. GE also has a strong installed base in Taiwan, with 30+ gas turbines, providing almost 6,000 MW of installed capacity. With our global experience across diverse industries, GE is well-positioned to support Taiwan’s 5+2 Industrial Innovation Plan, which focuses on seven industries and projects that will promote innovation, create high-income job opportunities, and support balanced development in high-value business sectors.

Most recently, GE Gas Power selected Taiwan as the first stop in Asia to host the GE Innovation Excellence Awards, where students presented creative ideas to help solve energy development issues. See how some of these proposals are taking shape.

Hydrogen-ready gas turbines

Supporting Taiwan's decarbonization journey with hydrogen

GE is the world leader in the application of fuels containing hydrogen in gas turbines. Over the last 30 years, our turbines have logged more than 8 million operating hours operating on hydrogen and associated low-Btu fuels using concentrations ranging from 5% to 95% (by volume) of hydrogen. GE recently announced new HA-powered pilot projects focused on demonstrating power plants capable of operating on hydrogen. GE’s H-class gas turbine portfolio currently has the capability to burn up to 50% by volume with a future path to 100% of hydrogen when blended with natural gas. This experience has helped GE become one of the world leaders in the application of fuels containing hydrogen in gas turbines.

Browse the assets below for more information, including webinars we have hosted on the topic of decarbonization and the use of hydrogen in gas turbines, and recent news and events illustrating milestones in our decarbonization efforts.

Services

Repairs and service centers in Asia

With local repair capabilities and the strength of our global expertise, GE is the service provider of choice in Asia, where we have 90% in-region self-sufficiency for heavy-duty gas turbines—including the HA. The Advanced Manufacturing & Repair Technology Center (AMRT) in Singapore is dedicated to providing H-class combined-cycle plant operators with fast support.

*Trademark of General Electric Company

繁體中文

繁體中文