Supporting Thailand’s energy future

The right solution for Thailand’s power needs

With a goal of reaching carbon neutrality by 2050 and net-zero greenhouse gas emissions by 2065, Thailand needs an energy partner with the right technology solutions to help the country continue providing reliable, cleaner power for its nearly 70 million residents.

More power, cleaner power, flexible power

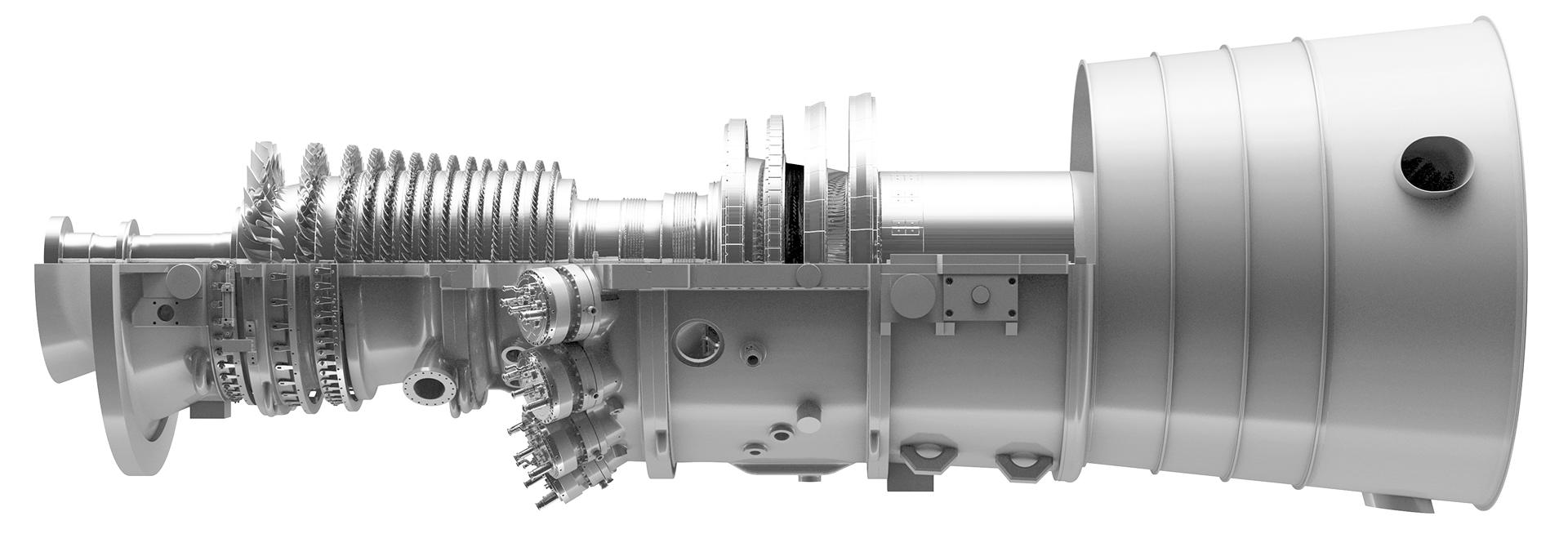

Introducing the 9HA gas turbine

Highly reliable and efficient to run, the 9HA gas turbine can help deliver the lowest cost per kWh as compared to other gas turbine technologies. In fact, the 9HA can deliver more than 64% net efficiency in combined-cycle operation.

Our gas turbines run on a variety of fuels that include hydrogen, making them a good solution to help meet decarbonization goals. With more power at a lower cost and reduced CO2 emissions—Thailand’s energy producers and consumers can enjoy reliable, cost-efficient electricity for the future.

The robust, proven 9HA gas turbine delivers many benefits:

- Record-breaking turbine efficiency

- Industry-leading operational flexibility

- Lowest emissions in the industry

- Hydrogen-ready

- Tried and tested, proven technology

- Modular configuration that reduces installation and cost

- Simple air-cooling architecture for easy plant integration

A leader in H-class technology

Providing energy efficiency and fuel savings

The highly efficient, air-cooled 9HA gas turbine is an industry leader in the H-class space, delivering exceptionally low lifecycle costs per megawatt.

Combined-cycle efficiency

Lowest cost conversion of fuel to electricity

The 9HA.02 gas turbine is an industry leader in the H-class space, delivering exceptionally low lifecycle costs per megawatt. Over its lifecycle, total cost of ownership of the 9HA.02 gas turbine is 5% lower than GE’s F-class—driven by lower capex, simplified configuration, decreased fuel cost from industry-leading efficiency, and extended maintenance intervals and reduced maintenance cost for H-class technology.

Operational flexibility

Leading the gas turbine industry

GE’s H-class combined-cycle power plant has industry-leading flexibility with startup to load in less than 10 minutes, the quickest ramp rate in the industry—full combined-cycle plant load in less than 30 minutes—and 7% standby mode. This flexibility gives customers the ability to reduce fuel consumption, avoid costly shutdowns, improve the lifecycle of the equipment, and remain online and ready to provide power quickly when renewable resources aren’t available.

Lower CO2 emissions

Powering Thailand towards decarbonization with the lowest emissions in the industry

The 9HA’s DLN 2.6e combustion system offers a step change in performance, emissions, and fuel flexibility. The DLN 2.6e maintains many of the elements of GE’s DLN 2.6+ combustion system and introduces advanced premixing for reduced NOx emissions while enabling high plant efficiency. Its advanced premixer enables expanded fuel flexibility to operate on both “rich” and “lean” gaseous fuels, a 50% hydrogen (H2) capability with a future technology pathway to 100%, a gas turbine turndown to more than 30% load, and an optional park mode at 7-15% load, further reducing customers’ operating costs.

Proven technology

Tried and tested gas turbines

Installing a gas turbine in your plant shouldn’t involve any unknowns. Across our HA fleet, each original turbine is put through several rigorous full-speed, full-load (FSFL) validation test at our Greenville, South Carolina facility. This $200 million investment allows us to push the units beyond real-world conditions—running the turbines at 110% of their rated speeds at load and replicating the harshest conditions. This type of extreme testing is possible because the gas turbine operates independently from the restriction of the power grid, enabling a much wider testing envelope than an on-grid facility.

Industry recognition

3rd party recognition for industry excellence

GE is the only original equipment manufacturer (OEM) that has been previously recognized by a 3rd party for setting two world records for powering the most efficient plant in an H-class combined-cycle (CC) application: 63.08% gross CC efficiency at Chubu Electric’s Nishi Nagoya power plant in Japan (7HA, 60Hz), and 62.22% net CC efficiency at EDF’s Bouchain power plant in France (9HA, 50Hz).

In 2021, Southern Power Generation’s 1.4 GW Track 4A power plant, a natural gas-fired power plant in southern Malaysia—equipped with the first commercial GE 9HA gas turbines—was recognized by POWER Magazine as their “2021 Power Plant of the Year” and by Diesel & Gas Turbine WORLDWIDE as “Power Plant of the World”, a meaningful model for balancing climate awareness, energy affordability, and reliability.

In addition, GE’s HA technology was adopted at China Huadian Corp’s Juliangcheng plant to help accelerate the retirement of existing coal-fired capacity and replace it with new, highly efficient combined-cycle gas turbines—an important role that earned POWER Magazine’s “ReinventionAward”.

Global experience

Proven technology throughout the world

GE introduced H-class technology to the industry 26 years ago. Today, GE’s HA product portfolio—first introduced in 2014—was engineered to reduce carbon emissions and to help support today’s flexible power generation model. The H-class portfolio leverages GE’s advanced combustion and compressor technology along with critical advancements in material science, design and coatings for higher output and performance.

GE’s HA portfolio is the world’s fastest-growing fleet in its class with more than 129 gas turbines ordered by 50+ customers across 20 countries. Our HA technology has accumulated more than 1M operating hours (as of August 2021) at 30 customer sites globally, and 2/3rd of our HA operating fleet has 16K+ operating hours.

Simplified modular construction

Faster installation reduces time and cost

GE’s gas turbine packaging, available on all H-Class gas turbine models, leverages a lean, modular, prefabricated approach and is engineered for:

- Easier installation; reducing gas turbine installation schedule by up to 8 weeks

- Simplified unit maintenance with easy access to the gas turbine accessory systems

- Increased safety onsite

- Lower project risk

- More efficient inspection and maintenance

- Reduced gas turbine installation labor (about 13K man-hours)

The gas turbine enclosure features modular architecture with valves, piping, and electrical systems packaged into stackable modules allowing for simultaneous installations and reduced safety concerns and delays due to interfering tasks.

Hydrogen-ready gas turbines

Supporting Thailand's decarbonization journey with hydrogen

GE is the world leader in the application of fuels containing hydrogen in gas turbines. Over the last 30 years, our turbines have logged more than 8 million operating hours operating on hydrogen and associated low-Btu fuels using concentrations ranging from 5% to 95% (by volume) of hydrogen. GE recently announced new HA-powered pilot projects focused on demonstrating power plants capable of operating on hydrogen. GE’s H-class gas turbine portfolio currently has the capability to burn up to 50% by volume with a future path to 100% of hydrogen when blended with natural gas. This experience has helped GE become one of the world leaders in the application of fuels containing hydrogen in gas turbines.

We have hosted several customer webinars on the topic of decarbonization and the use of hydrogen in gas turbines. Browse these webinars below—now available on demand—to learn more from our GE and other industry experts.

Did you know?

GE’s legacy of innovation

Focused on the future

From Thomas Edison’s first incandescent light bulb to the latest gas turbines that provide energy for power plants and jet engines alike, no other American-born company has a heritage of innovation as deep as GE. For the last 150 years, GE has been committed to making continuous progress to help propel technology forward and create a brighter tomorrow. Today, GE is a leader in the fields of power, aviation, healthcare, digital technology, and renewable energy.

Local presence

Working together to grow Thailand’s power economy

GE has had a presence in Thailand since 1900 when it began selling lightbulbs. Today, GE is one of Thailand's largest foreign infrastructure providers with businesses including energy, aviation, and healthcare. We are committed to providing solutions that will help improve living standards across the country, improve the efficiency, productivity, cost and emissions of gas power generation, and drive continuous growth as we take on new, emerging challenges.

Featured video

The First 9HA.02 in Thailand at Bang Pakong gas plant

To help ensure efficient and reliable power for Thailand, EGAT has partnered with GE to build the country’s first power plant featuring a GE’s 9HA.02 gas turbine. The Bang Pakong plant is expected to generate 1.4 GW of power; equivalent to powering ~3M homes in the region.

Further Reading

Learn more

Services

Repairs and service centers in Asia

With local repair capabilities and the strength of our global expertise, GE is the service provider of choice in Asia, where we have 90% in-region self-sufficiency for heavy-duty gas turbines—including the HA. The Advanced Manufacturing & Repair Technology Center (AMRT) in Singapore is dedicated to providing H-class combined-cycle plant operators with fast support.

ไทย

ไทย