Powering Saudi Arabia forward

Best-in-class decarbonization solutions

Saudi Arabia is experiencing a surge in both GDP growth and energy production needs. At the same time, the region’s Saudi Vision 2030 plan calls for a 35% reduction in greenhouse gas emissions and a balanced energy mix of 50% renewable resources and 50% natural gas—with a 2060 pledge for net zero.

GE is committed to helping meet these goals with hydrogen-ready gas turbines and gas turbine upgrades that can support this energy mix—as well as lower emissions even further through hydrogen and carbon capture solutions. GE has the latest hydrogen-capable gas turbine technologies to help Saudi Arabia reduce emissions and help meet the region’s decarbonization goals, as well as hydropower technologies to address ever-increasing power demand.

The latest technology

Solutions for Saudi Arabia

- H-class gas turbines

- Aeroderivative gas turbines

- Pumped hydro storage

- Services for 7E gas turbines

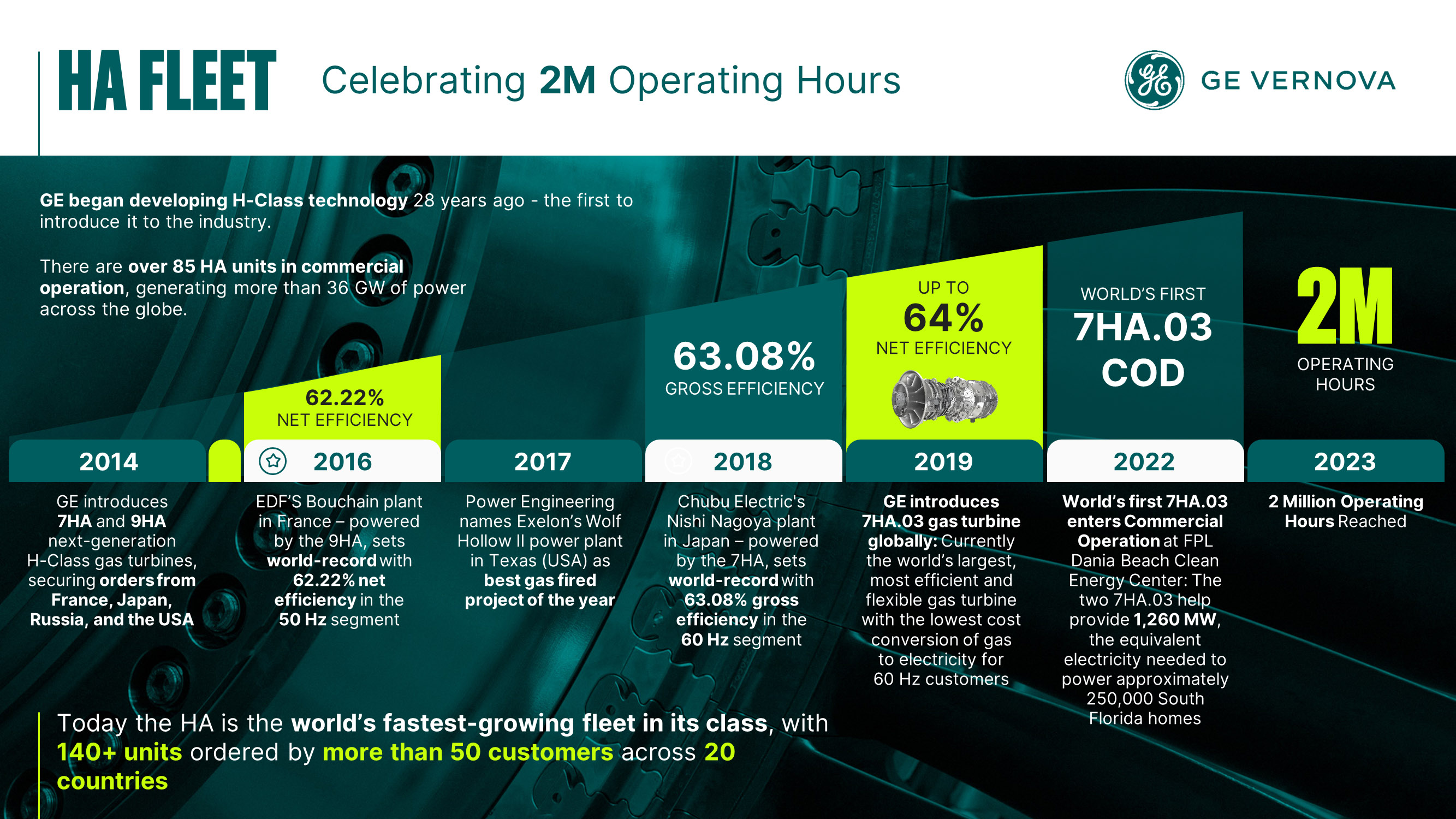

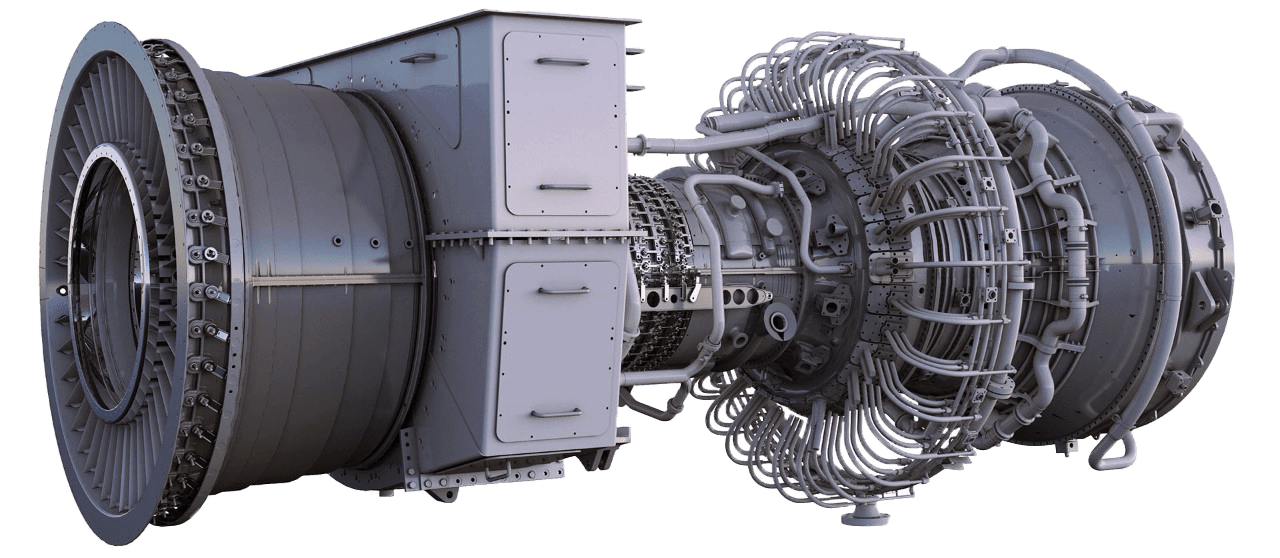

We introduced our H-class gas turbine technology to the industry more than 25 years ago. Our HA technology has accumulated more than 2 million operating hours at more than 50 customer sites globally, and 2/3 of our HA operating fleet has 16K+ operating hours. Today, GE’s H-class gas turbine portfolio has the capability to burn up to 50% by volume of hydrogen when blended with natural gas, with a path to 100% hydrogen.

7HA gas turbines are up to 50% hydrogen (H2) capable with a technology pathway to 100%. The 7HA.03 gas turbine is the most efficient 60Hz gas turbine in the world. This latest technology features more than 64% combined-cycle efficiency, higher than any other competing technology available today.

With the 7HA gas turbine, you will benefit from:

- Higher combined-cycle efficiency

- Up to 50% hydrogen capable

- Operational flexibility—operating with natural gas or liquids

- Industry-leading reliability and availability

- Up to 430 MW of additional power

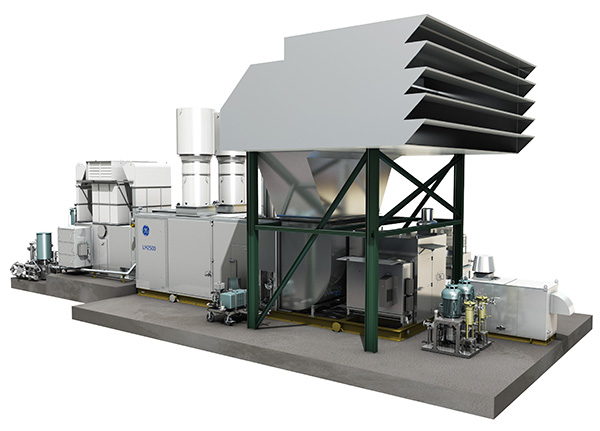

Featuring industry-leading performance, GE’s aeroderivative gas turbines can help address the challenges of the energy trilemma—affordability, availability, and sustainability—by operating concurrently with both conventional and renewable energy. With the ability to reach full power in five minutes, their plug-and-play nature provides quick, flexible, efficient power where it is needed. GE’s aeroderivative gas turbines are also fuel flexible, with the ability to operate on an 85/15 hydrogen/natural gas blend—helping pave the way for Saudi Arabia’s hydrogen-powered energy future.

Browse our aeroderivative gas turbines for Saudi Arabia below.

The LM2500XPRESS* can run on 35% hydrogen, and when an SCR is added to the unit to reduce emissions even further, NOx can be reduced to 2.5 ppm and CO to 4ppm.

The LM6000 offers 99%+ reliability and 98% availability. It can start up in 5 minutes, and its dual-fuel capabilities provides fuel flexibility and helps customers meet emissions limits.

Introducing the LM2500XPRESS: Modularity, reimagined

With up to 95% assembly in the factory, the LM2500XPRESS was created for speed and simplicity.

Powering Tanzania

See how GE’s LM6000 aeroderivative gas turbines are helping the Songas power plant in Tanzania provide power when hydro is scarce.

Article

Enabling Saudi Arabia’s energy transition

Saudi Arabia has been making extensive efforts to become a key player in the transition towards lower carbon energy sources. While the Saudi Vision 2030 plan calls for a 35% reduction in carbon emissions and a 50/50 energy mix of renewables and natural gas, the Kingdom has also committed to achieving net zero carbon emissions by 2060. Read on to learn how aeroderivative gas turbines can help Saudi Arabia reach its net zero goal.

Hydropower can play a defining role in the energy transition, thanks to the balancing and system services that facilitate the integration of variable renewables on the grid. For that reason, hydropower will be a key solution for Saudi Arabia to help decarbonize and diversify the region’s energy mix and enable the ongoing energy transition.

With higher needs for storage and grid support services, pumped hydro storage is the natural large-scale energy storage solution. It provides all services from reactive power support to frequency control, synchronous or virtual inertia and black-start capabilities. It brings support that was previously managed by fossil-fueled power plants but with even more reactivity and in a sustainable manner without CO2 emissions.

For many years, pumped hydro storage has offered a cost-effective way to provide reliable large-scale balancing and grid services. New pumped hydro storage technologies—such as variable speed capability—give plant owners even more flexibility by providing grid frequency support in both directions (in turbine and pump modes) as well as quicker response times. The high inertia of rotating machines can also stabilize the grid in case of disturbances, which influences grid frequency, enabling low-inertia renewable energies, such as wind and solar to enter the grid and allowing their power to be transmitted over great distances

With pumped hydro storage, you will benefit from:

- Unprecedented storage scale: 100x storage capacity vs. battery solutions

- Sustainable: 40-80 years lifetime GWh of storage

- Limited environmental footprint: closed-loop configuration, use of existing mines as reservoirs

- Dispatchable renewable energy: Match consumption and demand, integrate variable renewables

- Highly flexible and reactive power solution: up to 400 MW in less than 70 secondsr

- Grid support capabilities: balancing, ancillary services

Improving your performance

With more renewable energy sources being added to the grid, it’s more business-critical than ever that you 7E plant can operate in new and flexible ways to reduce emissions and stay competitive. GE has a suite of upgrades to help expand your operational flexibility, generate low-cost peak MWs, increase hours and starts, and enable your gas turbine to run on tri-fuels.

Decarbonization

More power, less emissions

Our upgrade solutions can boost the reliability and flexibility of your gas turbines while reducing their environmental footprint—to help meet or exceed current emissions regulations.

Renewables integration

Faster starts, lower costs and greater fuel flexibility

If your power plant’s 7E gas turbines are running as peaker units for more seasonal use when grid demand is high, you need solutions to help increase your output and heat rate, achieve faster starts, extend maintenance intervals to reduce your O&M costs, and make your gas turbines more fuel flexible to help integrate intermittent renewable power. Browse our offerings here.

Uninterrupted power

Increase your reliability, availability, efficiency and output

If your power plant’s 7E gas turbines are running all the time, you need them to be reliable, available, and efficient with the highest possible output. GE Gas Power has a wide range of 7E gas turbine upgrades that will help improve your overall combustion capability. Browse our offerings here.

Local presence

Technology, talent and services

GE has long supported Saudi Arabia with the latest power generation technologies, talent development and economic diversification programs, and value-add exports. With up to 470 GE gas turbines already providing ~45 GW of power to the region, and one of the world’s largest gas turbine service centers situated locally, GE is providing for our customers throughout Saudi Arabia—and beyond.

Video

Playing a key role in Saudi Arabia’s low carbon future

Saudi Arabia is committed to net zero carbon emissions by 2060, and GE Vernova is supporting that goal with investments in new technologies like H2 blended fuels and carbon capture to help achieve a lower carbon future. Through our GE Manufacturing and Technology (GEMTEC) in Dammam, GE Vernova is supporting the goals of Saudi Vision 2030 to diversify the Kingdom’s economy while supporting local suppliers and nurturing a new generation of energy professionals.

Decarbonization updates

Learn what's happening in the region

GEMTEC Campus

Driving energy supply chain localization

Opened in 2011, the GE Manufacturing and Technology Center is playing a strong role in helping to achieve the goals outlined under Saudi Vision 2030 by nurturing local talent and suppliers, further diversifying Saudi Arabia’s economic base, promoting exports, and much more.

Embracing diversity

FieldCore’s first female-led outage in Saudi Arabia

We are committed to providing power to the communities that need it the most, while developing our teams and embracing diversity and inclusion. This is the story behind the Advanced Gas Path upgrade on two 9F gas turbines executed in Saudi Arabia and delivered to our customer in Bangladesh.

Further reading

Learn more

*Trademark of General Electric Company