The Operational Availability Metric View illustrates for a single production unit how much time the unit was available for production and not down for one of the following reasons:

Turnaround Down Day

Routine Maintenance Down Day

Routine Maintenance Slowdown Day

Regulatory Process Down Day

Regulatory Process Slowdown Day

Each level of the Metric View displays a percentage of available time using the following equation:

...where:

Time is the number of days for which the production data exists.

Short Range Plan is the Short Range Plan value for any day for which the production data exists.

Note: If a production unit produces more than one product, where each of those products has its own production plan and Short Range Plan values, the sum of those Short Range Plan values is used in the equation. This is illustrated in the example following this list.

TADD is the amount of product that was lost due to a Turnaround Down Days (i.e., the Impact Code is TADD).

RMDD is the amount of product that was lost to a Routine Maintenance Down Day (i.e., the Impact Code is RMDD).

RMSD is the amount of product that was lost due to a Routine Maintenance Slowdown Day (i.e., the Impact Code is RMSD).

RPDD is the amount of product that was lost due to a Regulatory Process Down Day (i.e., the Impact Code is RPDD).

RPSD is the amount of product that was lost due to a Regulatory Process Slowdown Day (i.e., the Impact Code is RPSD).

Note: If you have created custom impact codes to categorize your data, you will need to modify the calculation for the Operational Availability Metric View in the Production Data cube in SQL Server Analysis Services. Instructions for completing this task are not provided in the Meridium APM Documentation. For more information, consult your Microsoft documentation.

For example, assume that for Unit 1:

Production data exists for January 1 through January 10. So, time is 10 (ten days).

Unit 1 produced both bottles and labels during those ten days.

Unit 1 can produce 5,000 bottles per day and 8,000 labels per day.

Within the ten days, 24,500 bottles and labels were not produced as a result of Turnaround Down Days.

Within the ten days, 8,200 bottles and labels were not produced as a result of Routine Maintenance Down Days.

Within the ten days, 19,500 bottles and labels were not produced as a result of Routine Maintenance Slowdown Days.

Within the ten days, no Regulatory Process Down Days occurred.

Within the ten days, 14,200 bottles and labels were not produced as a result of Regulatory Process Slowdown Days.

Using this data, Mechanical Availability is calculated using the following values:

Time = 10

Short Range Plan = 13,000 (i.e., 5,000 + 8,000)

TADD = 24,500

RMDD = 8,200

RMSD = 19,500

RPDD = 0

RPSD = 14,200

Remember that Mechanical Availability is calculated as:

...so:

Operational Availability = (10 x 13,000 - [24,500 + 8,200 + 19,500 + 0 + 14,200] / [10 x 13,000]) x 100

Operational Availability = ([130,000 - 66,400] / 130,000) x 100

Operational Availability = (63,600 / 130,000) x 100

Operational Availability = .4892 x 100

Operational Availability = 48.92%

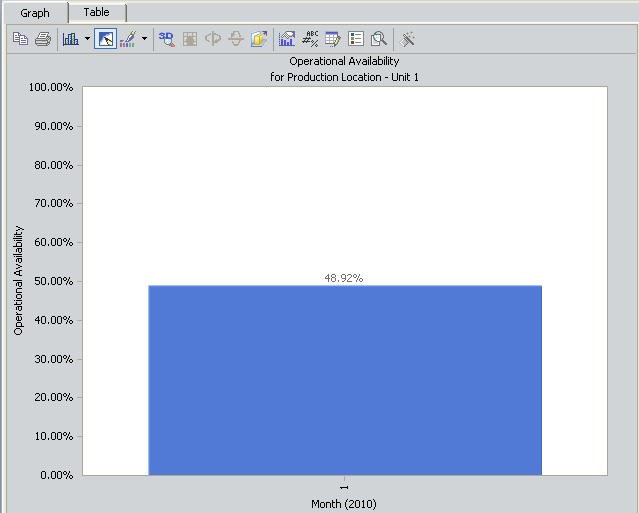

In this case, if you were to view the Operational Availability Metric View for Unit 1, the level that displays Operational Availability for January would look like this, where the month of January is displayed on the x-axis, and the operational availability is displayed on the y-axis as a percentage:

In other words, from January 1 through January 10, Unit 1 operated 48.92% of the time without experiencing a Turnaround Down Day, Routine Maintenance Down Day, Routine Maintenance Slowdown Day, Regulatory Process Down Day, or Regulatory Process Slowdown Day.

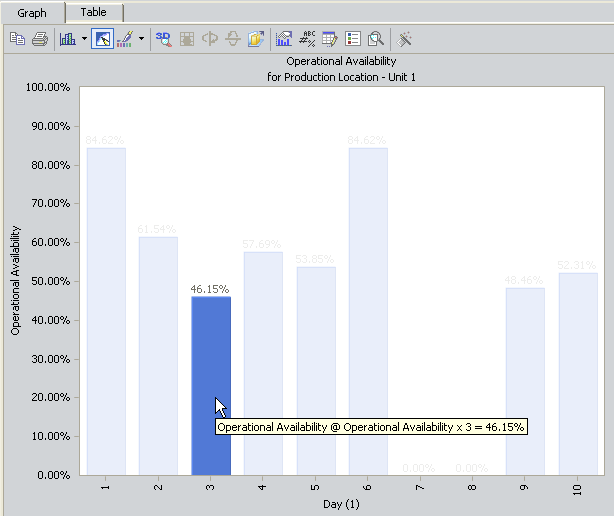

If you were to drill down into the next level of the graph, you would see this:

Here, you can see that for day 3 (January 3), Unit 1 was available 46.15% of the day without experiencing Turnaround Down Day, Routine Maintenance Down Day, Routine Maintenance Slowdown Day, Regulatory Process Down Day, or Regulatory Process Slowdown Day. This value is calculated using the following values.

|

Product |

Date |

MSCR |

Losses |

Impact Code |

|---|---|---|---|---|

|

Bottles |

1/3/2010 |

5000 |

3000 |

RMSD |

|

Labels |

1/3/2010 |

8000 |

4000 |

RMSD |

Using these values, for January 2:

Time = 1 day

Short Range Plan = 13,000 (5,000 + 8,000)

TADD = 0

RMDD = 0

RMSD = 7,000

RPDD = 0

RPSD = 0

...Operational Availability is calculated as:

Operational Availability = ([1 x 13,000 - 7,000] / [1 x 13,000]) x 100

Operational Availability = .4615 x 100

Operational Availability = 46.15%

Copyright © 2017 General Electric Company. All rights reserved.