Gas generator testing and inspection services

Explore our industrial generator inspection services

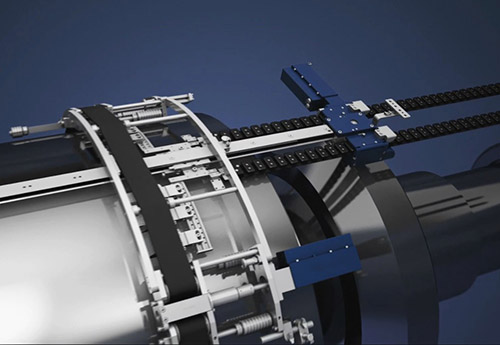

Generator airgap robotic inspection with rotor in-situ (offline)

GE’s offline generator inspection solutions include GE’s latest robotic tool technology that can perform a complete generator air gap inspection program with the rotor installed.

Our inspection tool can perform the following assessments:

- Visual inspection of the rotor surface

- Visual inspection of the stator surface

- Stator wedge tightness verification

- Stator low flux magnetic test

Generator retaining ring inspection scanner (offline)

GE’s generator retaining ring scanner is a robotic inspection tool engineered for detecting stress corrosion cracks without the need to remove the retaining rings from the generator. The inspection only requires minimal dismantling and can be carried out with the rotor in-situ or removed.

Generator testing and inspection program (offline)

GE’s test and inspection program is a set of modular solutions to thoroughly assess the condition of your generator during an outage. Based on decades of experience across one of the largest installed fleets, our diagnostic experts will provide you with a detailed analysis and recommendations for more reliable operation.

The inspection’s scope will match the allowed outage time and take into account the generator model in order to make sure all identified areas of concern are inspected.

Example tests include:

- Stator electrical tests (IR, PI Index, DC and AC Hipot)

- Stator low and high magnetic tests including PULSAR test

- Stator cooling water flow test (UT Flow)

- Stator endwinding vibration testing (Bump test)

- Rotor field electrical test (IR, RSO, DC Hipot)

- Rotor hydrogen seals pressure test

- Stator radial wedging test

- Brushless exciter diode test

CUPROPLEX* (online and off-line)

CUPROPLEX is a proven service to remove copper oxide build-up from stator bars and the cooling water system in order to restore cooling efficiency and avoid generator overheating damage.

CUPROPLEX is the only process that can be applied while the generator is online and in normal operation. For heavily flow-restricted bars we have developed CUPROPLEX-S.

- No disassembly of generator required

- Controlled process

- Reduced environmental impact—no hazardous liquid waste

- Return to full output in as little as two days

Enhanced generator outage preparation and execution

Generator outage management

We define the scope for your condition-based outage, leveraging our in-depth knowledge of all types of turbo generators and schedule the necessary actions to address the duration and lower downtime for your plant. We execute with qualified generator field specialists and the latest tool technology.

Customized gas solutions

Gas and combined-cycle generator training

GE Gas Power can provide customized training solutions to meet your individual needs, covering introductions for new employees, and development programs for your talents as well as individual training courses to bring your teams up to speed to safely execute their tasks during daily operations and generator field maintenance.

- Hands-on generator training courses based on simulations of real cases (portable simulator)

- Execution on GE premises or onsite

- Experienced instructors for each technical scope

Looking for more gas generator resources?

Additional resources

Videos

Learn how we can help with gas generators

Take a closer look at our generator solutions.

Explore our CUPROPLEX* inspection solution

Discover our generator services portfolio

Generator Health Monitoring (GHM) helps you avoid forced outages

Learn what a generator condition assessment can do for you