Product features

Decades of experience

GE brings decades of domain expertise to the Mark VIeS Functional Safety System. Complete, flexible, and reliable, the Mark VIeS adds another proven piece to our safety portfolio.

A proven and safe solution

Our philosophies are at the heart of the Mark VIeS Functional Safety System. The system can be configured to meet the safety requirements of specific applications by choosing the appropriate level of redundancy choices of simplex, dual, or TMR controllers, I/O network, and I/O modules.

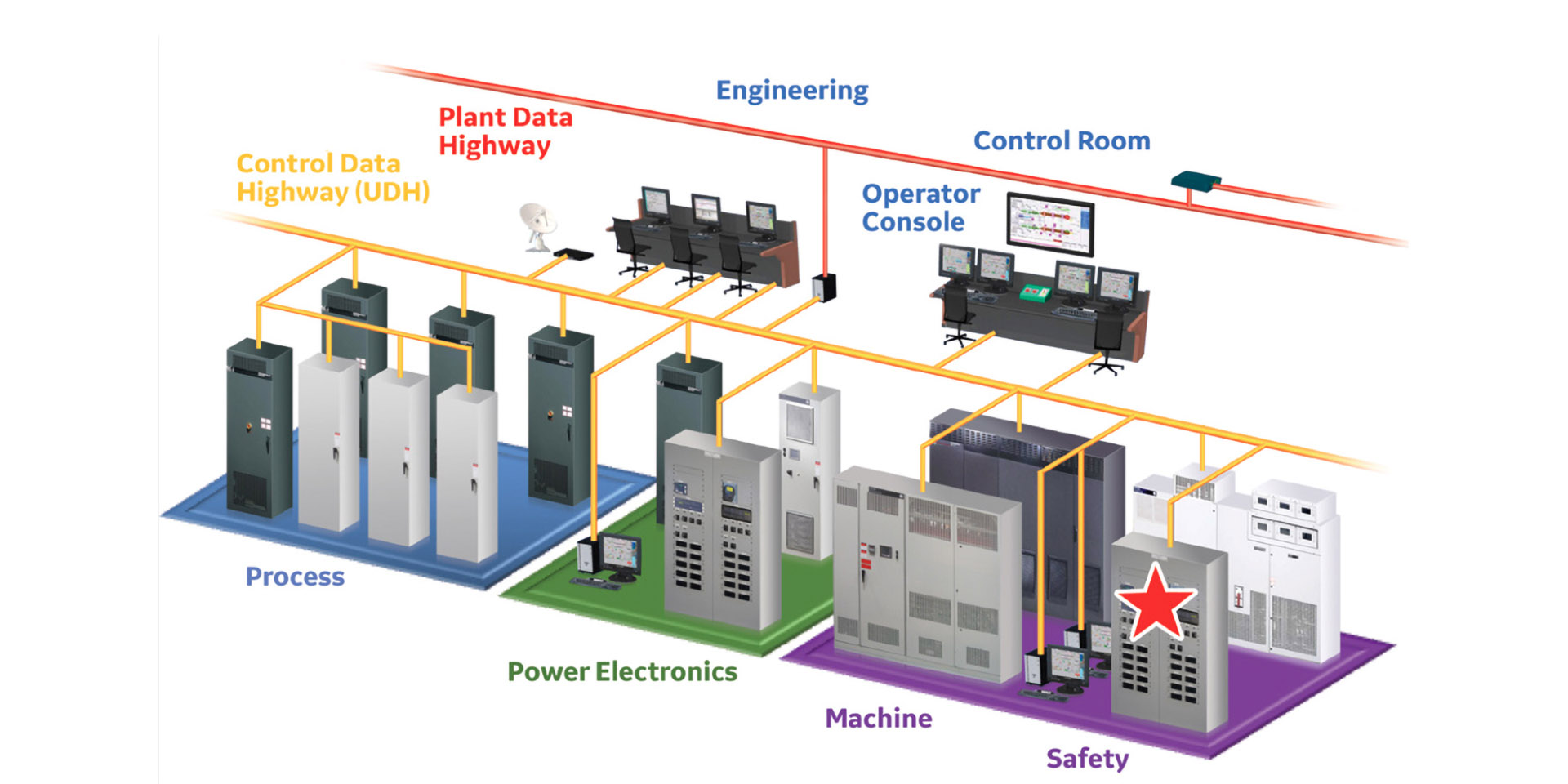

The Mark VIeS can be applied as a stand-alone safety application or as part of GE plant-wide control solutions. To help protect your infrastructure, the Mark VIeS system’s enhanced cybersecurity features integrate with GE plant-wide security management systems, providing perimeter defense and intrusion detection and protection against denial of service (DOS) attacks and buffer overrun.

Enhanced cybersecurity

The Mark VIeS system helps keep operations safe and secure through:

- Branded and locked application code

- Embedded cause-and-effect matrix programming

- Dedicated security process and response

- Limited data access

- Improved passwords

- Achilles Certification—Level 1

- User authentication and access control

- Security logs

- Hardened protocols

Reliability in harsh environments

GE understands that safety systems don’t just reside in clean rooms. That’s why the Mark VIeS Safety Management System provides high performance in the extreme conditions found in many process environments. The processors, network switches, and I/O components are approved for hazardous location, Class 1, Division—where the Mark VIeS can operate in temperatures ranging from -40° to 70° C without fans or other external cooling.

Integrate with existing control systems for better, faster decisions

GE understands the importance of seamless integration between your safety and basic process control solutions. The Mark VIeS offers flexibility, scalability, and common configuration and standards-based operational interfaces to integrate with basic process control systems. This allows world-class safety functionality to connect to existing processes, creating a seamless safety program and reducing the installed and operating costs of your control system.

The Mark VIeS enables real-time visualization by sharing data through plant-wide control systems, HMI, data historians, device management systems, and platform-wide trending tools. Key personnel gain access to critical operational information, allowing them to make better, faster decisions.

Enhanced productivity and performance

Sophisticated application automation tools and seamless data integration between the control system and HMI enable process efficiencies during project execution to reduce delivered cost and improve quality. Enhanced software reusability features allow users to create and maintain logic standards that can then be efficiently deployed over and over again. This reduces project costs, increases integrity of software, and reduces risk of human error. All critical considerations when deploying safety related systems.