The Energy of Change

Asia Pacific at a Glance

GE Vernova has more than 18,000 employees across Asia Pacific, with operations in more than 22 countries. Our advanced technology plays a critical role in advancing decarbonization and electrification to support Asia Pacific’s growing energy needs.

29

manufacturing facilities

10

repairs and services centers

45

joint venture (JV) entities in Asia Pacific

8

technology and R&D centers

Australia

GE Vernova Tooling Center, Perth

China

Repair and Service Center, Qinhuangdao

India

John F. Welch Technology Center, Bengaluru

Indonesia

UNINDO Transformer Manufacturing Facility, Jakarta

Japan

Global Nuclear Fuel (GNF) facility, Yokosuka

Singapore

GE Vernova Services Singapore (GEVSS)

South Korea

Heat Recovery Steam Generator (HRSG) Manufacturing Facility, Changwon

Vietnam

Wind Manufacturing Facility, Hai Phong

Malaysia

GE Vernova Tooling Center, Port Klang

Taiwan

GE Vernova Office Taipei

Thailand

Tooling Centre, Rayong

Vietnam

Heat Recovery Steam Generator (HRSG) Manufacturing Facility,

Dung Quat

India

Hyderabad Technology Center

GE Vernova in Asia Pacific

GE Vernova is powering Asia Pacific with all the businesses and teams coming together to lead the energy transition in the region through our advanced technologies.

Case Studies

Powering Asia

Resources

White Paper

Decarbonization pathways for Japan —Challenges in the power sector from 2023-2050

As Japan accelerates towards its ambitious target of achieving net-zero greenhouse gas emissions by 2050, GE Vernova is actively advancing this endeavor.

To learn more about the Japan energy outlook, read the White Paper.

On-Demand Webinars

Perspectives

press releases

Mon, 06/09/2025

Japan’s METI and GE Vernova launch joint focus group to bolster energy security and innovation

Fri, 06/06/2025

GE Vernova commissions India’s first variable speed pumped storage unit at the country’s largest hydropower complex

Wed, 05/14/2025

GE Vernova to invest USD $16 million to expand manufacturing footprint in India to meet rising demand for advanced grid infrastructure

Thu, 05/01/2025

GE Vernova to deliver extra high-voltage transformers and shunt reactors for renewable energy corridors in India

Thu, 04/17/2025

GE Vernova’s HA-powered Goi Thermal Power Station adds 2.3 GW of electricity to contribute to the stable supply of electricity in Japan

Thu, 04/03/2025

GE Vernova wind turbines power the start of operations for largest onshore wind farm in Japan, located in Fukushima

Thu, 03/13/2025

Powered by GE Vernova’s H-Class equipment, 1.2 GW Pulau Indah power plant starts commercial operation in Malaysia

Thu, 01/09/2025

GE Vernova announces order to provide onshore wind turbines for Eurus projects in Aomori, Japan

Thu, 01/09/2025

China’s Guangming Plant starts commercial operation, powered by GE Vernova’s H-Class equipment

Wed, 01/08/2025

GEベルノバ、ユーラスエナジーの青森県内風力発電所のタービンの受注を発表GEベルノバ、ユーラスエナジーの青森県内風力発電所のタービンの受注を発表

Mon, 01/06/2025

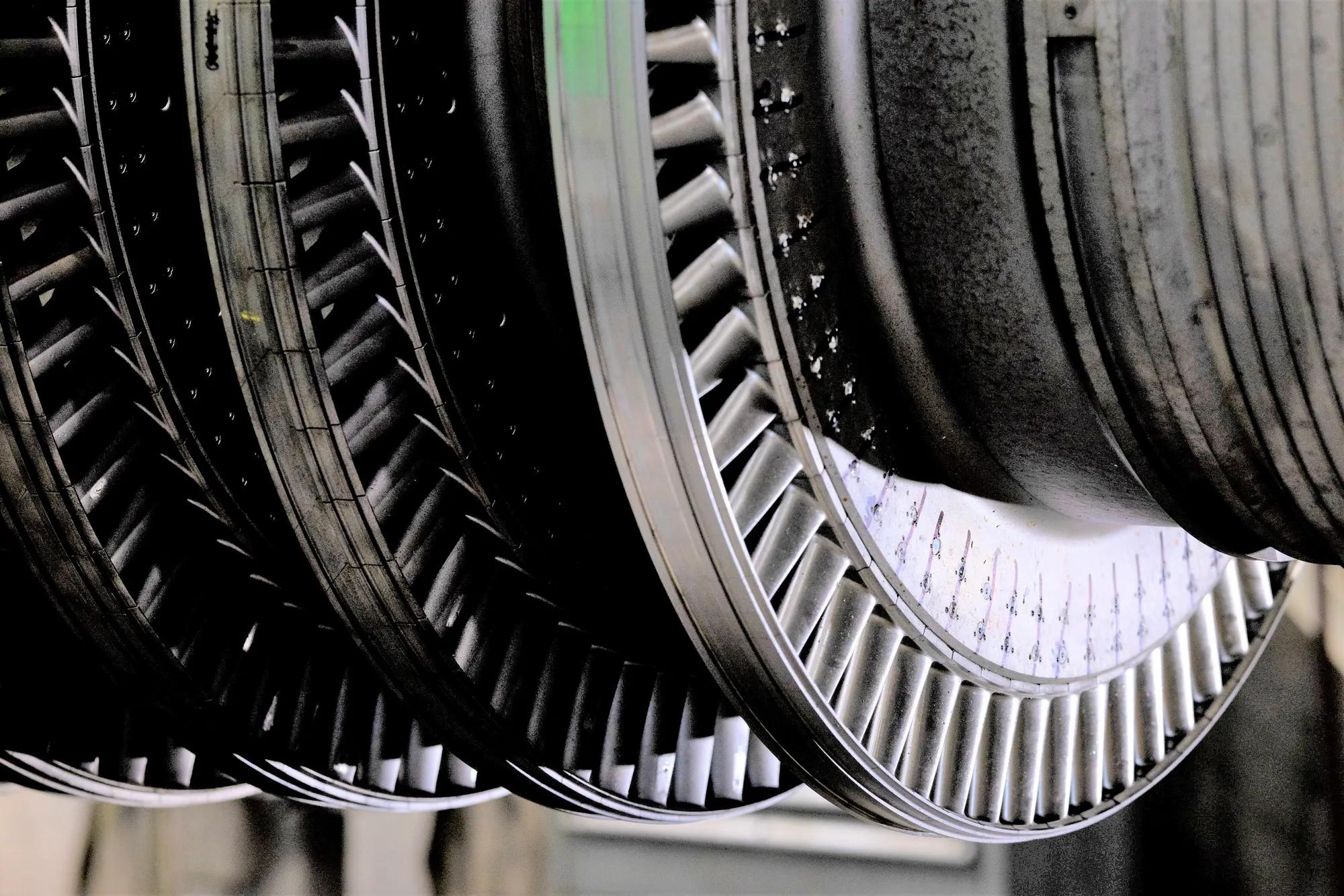

GE Vernova plans to invest USD$20M in Singapore to boost innovation in repair capabilities and technologies on next generation of its High efficiency, Air-cooled (HA) gas turbines

Thu, 11/14/2024

GE Vernova Foundation announces RENEW Skills Development Program to advance energy transition in Vietnam

Thu, 11/07/2024

GE Vernova celebrates commercial operation for HA-powered Tongyeong combined cycle power plant in South Korea

Thu, 10/24/2024

Powered by GE Vernova H-Class technology, Ningzhou power plant adds up to 2.4 GW of power to the national grid in China

Mon, 09/30/2024

GE Vernova signs agreement to supply turbines for 228 MW Boulder Creek Wind Farm in Australia