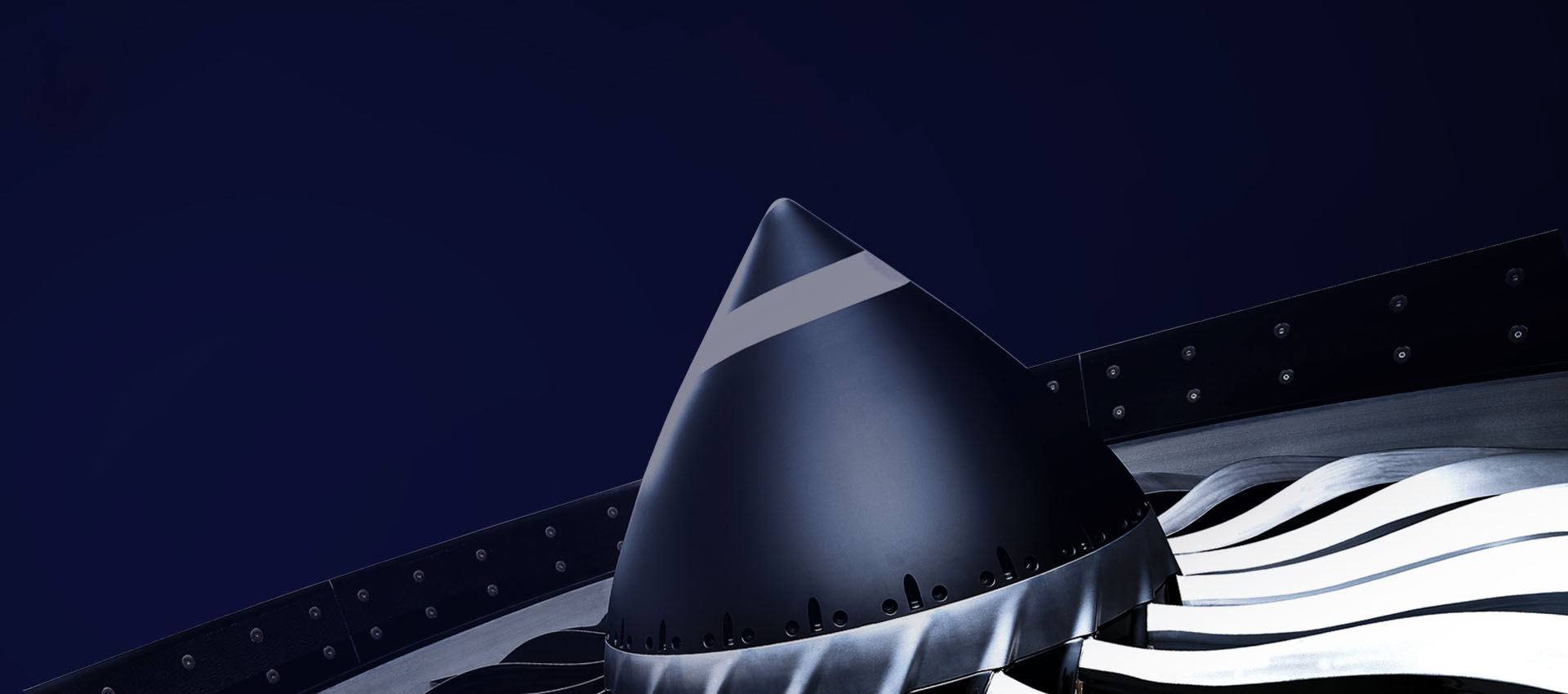

GE - Once, Now, Forever

We were meant to fly

~$32B annual revenue

- Powering 3 out of 4 commercial flights globally

- ~44,000 commercial engines*

- ~26,000 military engines*

NYSE: GE

*Includes engines made by GE Aerospace and its JVs

The Energy To Change The World

~$33B annual revenue

- Helping to generate ~30% of the world’s electricity

- ~55,000 wind turbines

- ~7,000 gas turbines

NYSE: GEV

Building a healthier future we can thrive in

~$19B annual revenue

- 1B+ patients served annually

- 4M+ installed base equipment

NASDAQ: GEHC