Understanding when to take advantage of metal 3D printing may not be as straightforward as you think. Some organizations have brought additive manufacturing in-house and ramped to full-scale production, while others are in exploration phases with the technology. From high-resolution parts to meshes to patient-specific components, 3D printing is transforming how medical device designers approach metal part design. Hear more about this from experts who regularly work with additive engineers from the medical industry.

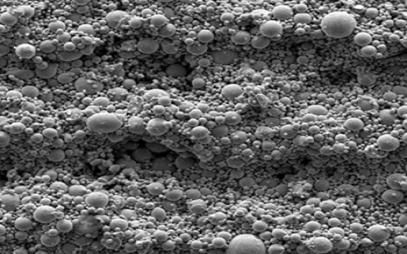

- Learn about the advantages of leveraging Direct Metal Laser Melting (DMLM) to produce your medical additive parts

- Explore the advantages of stainless steel, cobalt chrome and titanium in medical applications, and understand material limitations

- Hear about new technology applications and trends we are seeing for metal 3D printing

Speakers

Ted Anderson

Industrialization Leader

GE Additive

Ted Anderson is the industrialization leader for GE Additive. His team is focused on helping customers get their additive manufacturing applications to production. Prior to joining GE Additive, he spent five years with GE Aviation and was involved in the LEAP fuel nozzle, the GE9X TiAl blade, the 50% printed tech demonstration engine, the Catalyst turboprop engine and various R&D projects. He is also a certifying agent at GE for the laser and electron beam technologies and a special process auditor. Before joining GE, he worked as a contractor at NASA’s MSFC, managing the Rapid Prototyping Lab and working on a wide variety of R&D programs on multiple additive manufacturing platforms. Prior to being a contractor to NASA, he was the second Arcam employee in North America, working field service and applications for the EBM technology.

Eric Utley

Applications Engineer

Protolabs

Eric Utley is an applications engineer with more than 12 years of experience in rapid prototyping and additive manufacturing. He specializes in stereolithography, selective laser sintering and Direct Metal Laser Melting (DMLM) technologies and provides guidance to engineers on designing for manufacturability. Eric regularly consults with product development professionals from a range of industries including medical, consumer products, aerospace, and automotive. He graduated from North Carolina State University and currently works for Protolabs, a rapid manufacturing company specializing in custom prototypes and low-volume production parts.