The M2 Series 5 provides an increased level of productivity and faster builds that help drive lower cost for your business. Finer feature resolution, improved part quality and consistency enables you to unlock new revenue opportunities with new and innovative designs and builds.

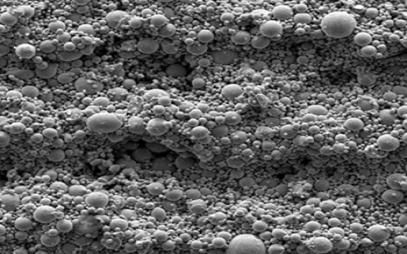

The powerful dual laser system provides up to 100% coverage per laser and 2x faster build speeds. Due to the small spot size of 70-500 microns, multiple exposure strategies within a single part are possible. The M2 Series 5 offers full control of the process critical variables. The flow-optimized build chamber provides a constant gas flow due to volume flow monitoring. In addition, multiple internal sensors ensure a more controlled build environment, resulting in significantly better part quality and consistency which are critical for safety relevant industries like aerospace and medical.

With the new all 2 x 1,000W laser option, the M2 Series 5 now offers even more productivity, safety and ease of use for the customer that further helps to reduce time and costs and increase profitability.

Speakers

Jon Ortner

Senior Product Manager

GE Additive

Jon Ortner is the Senior Product Manager for the GE Additive Concept Laser M2 machine. He started at GE Aviation as a mechanical engineer in 2007 & while there he worked as an additive manufacturing engineer & developed manufacturing processes & machine technology for Aviation part production. After the acquisition of Concept Laser, he relocated to Germany to develop machines to meet the demanding needs of GE Additive customers using additive manufacturing at scale.