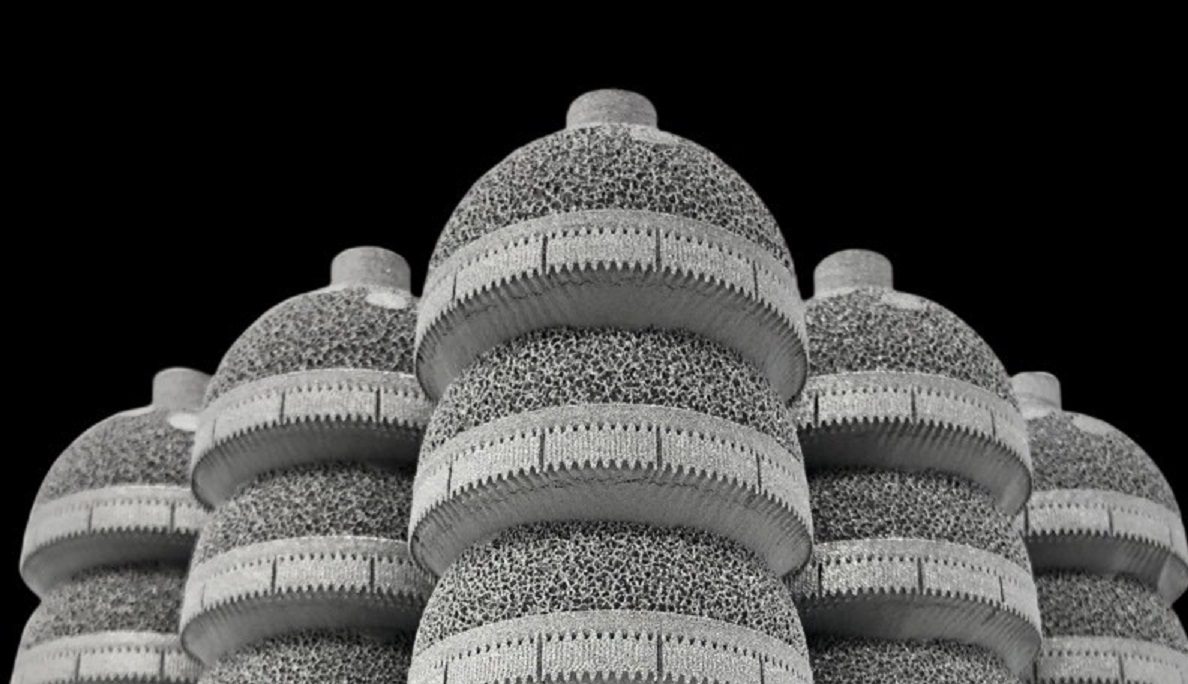

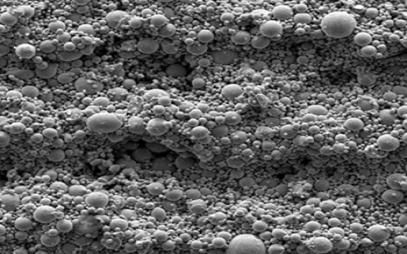

Brian McLaughlin, President, and Jonathan Buckley, Sr. AM Application Engineer, with Amplify Additive, will present how Electron Beam Melting (EBM) is the optimal technology for them to manufacture a critical component for successful Total Hip Surgery. Many animal studies have demonstrated the optimal pore size for bone in-growth in addition to initial fixation, which with additive manufacturing (AM) can be printed and implemented into the part design via trabecular and stochastic lattice generation. This webinar will not only discuss characteristics of AM that allow for optimization for improved patient satisfaction but also compare AM to traditional technologies, including supply chain considerations. In addition, a baseline comparison to other AM technologies, i.e. Selective Laser Sintering/Melting, will be provided showing key differences to EBM.

Speakers

Brian McLaughlin

Founder & CEO

Amplify Additive

Brian is the founder of Amplify Additive. He is passionate about orthopedics and is well-versed in all aspects of advanced manufacturing - from the industry’s leading innovators and product development to commercialization strategies and business trends. Creative and entrepreneurial by nature, Brian’s attention is on identifying opportunities for new business development in existing and emerging orthopedic markets, and in assisting companies looking to leverage AM technology.

Brian and his team at Amplify are focused on advancing Additive Manufacturing for Orthopedics, utilizing GE Additive’s EBM technology for innovative implant solutions across all indications. Brian has experience across all industry lines in the orthopedic market including design & manufacturing for a leading CMO; as a clinical specialist working directly with surgeons; as the VP of Engineering and co-founder of a Foot & Ankle implant company leveraging AM for implants; and now as the leader at Amplify Additive. Brian has a BS in Biomedical Engineering from the University of Vermont.

Jonathan Buckley

Senior AM Applications Engineer

Amplify Additive

Jonathan supports the team by managing EBM technology in the production of orthopedic and medical devices. Jonathan has extensive experience in the additive manufacturing field from his prior position at GE Additive. Jonathan joined Arcam EBM as an Applications Engineer and was responsible for managing customer technical issues North America wide, holding training courses to teach new and current EBM users on the technology, and providing technical support for pre-and-post sales activities. He continued to hold this position before and after GE’s acquisition of Arcam EBM and provided EBM knowledge and expertise to GE Additive during his tenure. He now provides this expertise to Amplify Additive.

Stephan Zeidler

Senior Global and Key Accounts Director

GE Additive

At GE Additive, Stephan Zeidler serves as a Senior Global and Key Accounts Director where he oversees medical industry-related strategy and business development activities. He is involved in Global Account Management and Product Management activities and continues to escort multiple companies, ranging from service providers, OEMs and global medical device manufacturers, on their additive journey. He joined GE Additive in 2016 as Global Business Development Manager for the medical sector and has more than seven years’ experience in the medical additive manufacturing industry. Prior to joining GE Additive, Stephan held Product and Key Account Management roles in the additive manufacturing industry working with multiple additive technologies such as PolyJet and FDM.