In the first webinar of this two-part series, we introduced the new 3D printed heat exchanger for GE Aviation’s GE9X jet engine. This new design has a completely different profile - one that includes optimized channels and complex internal geometries that take full advantage of AM’s design freedoms. We also discussed the large opportunity for growth of applications like this in the aerospace market segment. Click on the link above to watch Part 1.

At the conclusion of the webinar, we asked for feedback from attendees on topics they would like to hear about in more detail. We will use “Part 2” to address several of those topics.

Join James Bonar, GE Additive’s AddWorks leader focused on new product integration and technology maturation programs; Mark Fuller, senior designer with more than a decade of AM experience; and Curt Hogan, additive technologies design engineer, as they discuss:

- Management of complex CAD geometries

- Details on the development process of an AM heat exchanger

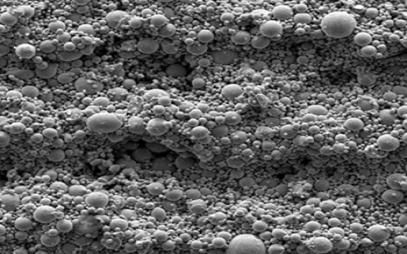

- Characterization of additive critical engine parts

- Certification and qualification of thermal management devices for aerospace

Speakers

James Bonar

AddWorks people leader focused on new product integration and technology maturation programs

GE Additive

James Bonar has 10 years of aviation experience at GE. He has executed both new-product integration and technology maturation programs. James worked on some of the earliest trade studies at GE in both military and commercial programs to understand additive thermal technologies and the potential to reduce part counts, increase performance, reduce cost, and change the traditional supply chain. The furthest maturity of these efforts resulted from his leading the additive heat exchanger team through GE9x certification for production. James is a GE Additive AddWorks people leader and has a Bachelor and Master’s of Mechanical Engineering degrees from the University of Cincinnati.

Mark Fuller

Senior Designer

GE Additive

Mark Fuller is a senior designer with 11 years of experience in additive manufacturing. He started with GE Additive in 2017 and before that Gulfstream Aerospace. He is extremely passionate about additive manufacturing and pushes the limits of the technology daily. Mark enjoys helping customers on their metal additive journey. He has designed a wide variety of DMLM parts for military heat exchangers as well as larger 250lb rocket parts. Back in March of 2020 his simple plastic 3D-printed face mask was certified and approved for use by the Navy and National Institute of Health. To date, over 200,000 units have been produced to help with the fight against Covid-19.

Curt Hogan

Advanced Lead Engineer

GE Additive

Curt Hogan is a mechanical engineer who enjoys the details of data. A University of Cincinnati graduate with Bachelor and Master’s degrees in Mechanical Engineering, Curt has nine years of experience with GE, including five years designing additively manufactured aviation components. He is a former hardware owner of several new product introductions for GE Aviation, including the first aluminum additive heat exchanger certified by the FAA for use on the GE9X engine. Curt is currently an advanced lead engineer within GE Additive’s AddWorks team, continuing to progress the thermal technologies of additive for both commercial and military applications.