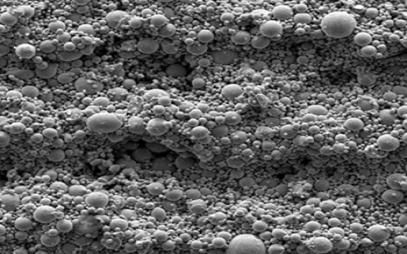

Additive manufacturing is reinventing the way we work and is poised to forever transform the world of design and manufacturing as we know it. Unlike conventional manufacturing methods that mill or cut away from a billet to produce a final part, additive technologies (also referred to as 3D printing) "grow" parts directly from a CAD file using layers of fine metal powder and usually an electron beam or laser heat source.

The result is geometrically complex and fully dense parts with less waste, manufactured in a fraction of the time it would take using other methods. We can now make parts and products that were once thought impossible to produce, this has provided an entirely new toolbox for engineers and designers to use when solving difficult problems; enhancing durability, increasing reliability, reducing weight, reducing cost, and, in some cases, disrupting long-standing industries.

GE is all-in to exploit the advantages that additive offers with several hundred machines in use across the company and a significant annual investment in research and development. In this lecture, Joshua Mook will give an overview of the latest in metal additive technology and innovation at GE Additive. He will cover the current state-of-the-art for fabricating functional parts and discuss the impact that additive is having on design and manufacturing. He will also explore the unique challenges involved in designing parts for additive manufacturing, including the need for organizations to rethink long-standing design approaches and the advanced design techniques and tools to take full advantage of new design freedoms offered by using additive manufacturing.

Darryl Chan

Honorary Secretary

Royal Aeronautical Society (Hong Kong Branch)

Darryl runs a management consultancy in Hong Kong and was formerly Head of Engineering at Cathay Dragon. Previously, he held various engineering leadership positions in Cathay Pacific Airways. Darryl was a product of their graduate engineering training programme after finishing his Air Transport Engineering degree from City University, London UK.

Giving back to the industry is a key principle, and Darryl is active in the Hong Kong Institute of Engineers, Aircraft Discipline/Division and Royal Aeronautical Society (Hong Kong Branch). He also sits on the advisory committees of the Hong Kong University Mechanical Engineering Department, the Polytechnic University Mechanical Engineering and Aeronautical & Aviation Engineering Departments.

Josh Mook

Innovation Leader

GE Additive

As an engineering leader for GE Additive, Josh Mook is leading a team to accelerate additive adoption across the world and to facilitate customers on their own additive design and manufacturing journeys.

Josh joined GE Aviation in 2005 as a product design engineer and has spent 12 years advancing his career in design and development of GE's commercial and military engines. In 2008, Josh joined the GEnx airfoils team where he led design programs for flowpath hardware. In 2011, he was selected to lead the LEAP fuel nozzle design team through design and certification. As the leader of an additive engine demonstrator program later named the A-CT7, Josh oversaw fast-track development and testing of a derivative engine that enabled a more than 8 percent reduction in engine weight and an 8 percent reduction in cost.

Josh is a 2008 graduate of GE’s Edison Engineering Development Program. He holds a Bachelor of Science in Aeronautical and Astronautical Engineering from Purdue University and a Master of Science in Aeronautical and Astronautical Engineering from the University of Cincinnati.