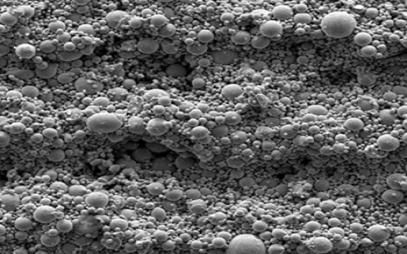

This webinar will explain the role of the materials engineer throughout the entire additive manufacturing process. Every aspect of the additive process can impact the end-state material properties. This presentation will focus on metal powder characteristics, machine hardware and process settings, part geometry, thermal processing, and surface treatments, and the effects of each on material properties. Powder characteristics such as particle size and shape will affect how the powder is distributed in the print bed. Machine parameter settings such as beam power and shape, layer thickness, and gas flow all have different impacts on the resulting bulk material and surface quality. Part features and surface conditions can impact localized material behavior, while thermal processing affects the bulk microstructure and can be tailored to achieve certain material properties.

Presenter

Lyndsay Kibler, Lead Materials Application Engineer, GE Additive

Bio

Lyndsay Kibler is a Lead Materials Application Engineer working in GE Additive's AddWorks(TM) engineering consulting organization. She works with customers to develop the best materials solutions for their applications, consulting on all aspects of the additive ecosystem from a materials perspective. She has developed machine parameters, led characterization programs, and consulted with numerous customers on material performance and selection. Lyndsay specializes in nickel, aluminum, and titanium alloys for GE Additive's laser powder bed fusion platforms.

Lyndsay joined GE Power in 2013 as part of the Edison Engineering Development Program, and has held various roles across the power industry during her first two years with the company. In 2015 she joined the gas turbine Advanced Component Design team as a mechanical design engineer, where she led the design, development, and validation of an additive component from conceptual design through production introduction. Through this experience Lyndsay not only learned how to design for additive but also how to industrialize it. Lyndsay holds a Bachelor of Science in Materials Science & Engineering from Virginia Tech, and a Master of Materials Science & Engineering from North Carolina State University.