Additive manufacturing made history this year, with the first flight of the Boeing 777X powered by two GE9X engines. Each engine includes 300 additively manufactured components, proudly made by GE Aviation and Avio Aero. GE Aviation's additive journey began almost ten years ago with the reimagining of the fuel nozzle on the CFM LEAP engine and achieved FAA certification in 2015. Now other engines, such as the GE9X, are also realizing the benefits from additively manufactured parts. As GE Aviation learned, the path to serial additive production requires careful planning, patience, awareness of potential pitfalls, and enormous attention to detail - but, if done correctly, can also have enormous benefits, such as shorter production lead times, cost savings, consolidated part counts, reduced waste, improved sustainability and an enhanced supply chain. In this session, GE Aviation will share their story and lessons learned on their own path to production.

Speakers

- Steven Woods, Chief Manufacturing Engineer, Additive Integrated Product Team, GE Aviation

- Chris Schuppe, General Manager Engineering & Technology, GE Additive

Bios

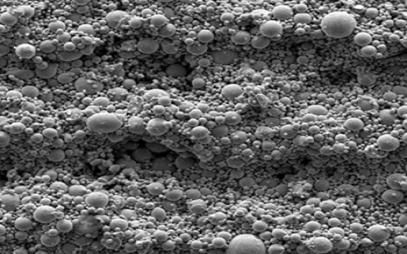

Steve Woods is the Chief Manufacturing Engineer for the GE Aviation Additive IPT (Integrated Product Team) in Cincinnati, OH. The Additive IPT is a cross functional team responsible for additive manufacturing supply chain production operations, footprint strategy, and successful industrialization of new product introduction. Within the organization, Steve is responsible for producibility and transitioning additive components to high volume production enabling supply chain fulfillment at competitive cost. Prior to this role, he was the Additive Manufacturing Leader for the GE Power Advanced Manufacturing Works organization located in Greenville, SC. In the past 6 years, he has been focused on industrializing gas turbine components with additive manufacturing on the top 3 DMLM OEMs offering a unique perspective.

Steve has a welding and joining background, strong manufacturing experience, creative problem-solving ability and global team leadership experience. He started his career with GE Aviation in 2006 as a Joining Engineer, joined GE Power’s Repair Development Center as a Lead Joining Engineer in 2009, and was technical leader for a repair engineering team supporting the global service centers.

Steve received his BS in Welding Engineering from The Ohio State University and his MBA from Xavier University.

Chris Schuppe began his career with Toyota in 1995 in Design and Evaluation.Chris moved to GE Aviation in 2000 and spent 16 years in Engineering working in Systems, Advanced turbine blade technology, mechanical systems, and externals integration. During this period he held several roles of increasing responsibility including NPI Team Leader, Black Belt, Module Manager and Subsection Manager.

Starting in the late 2000’s, Chris started working in additive in various forms including polymer and metal additive as well as more advanced materials. Chris’ teams in Aviation led to the creation of the LEAP fuel nozzle, the GE9X additive part including a first ever high pressure flight capable aluminum heat exchanger, the GE Catalyst engine which took 855 conventional parts and converted them to 12 as well as many others that are not public yet.

In October of 2016, Chris helped found GE Additive as the Engineering Integration leader for GE Additive and then led the GE Additive AddWorksTM team to accelerate additive adoption across all industries. AddWorks encompasses design, materials, industrialization consulting, low rate production and prototyping as well as the customer experience centers in Munich and Pittsburgh. Chris now leads the GE Additive Engineering & Technology teams helping advance the state of the art of additive machines and modalities.