WEBINAR: Realize the Benefits of Large Joint Additive Manufacturing with Zero Compromise

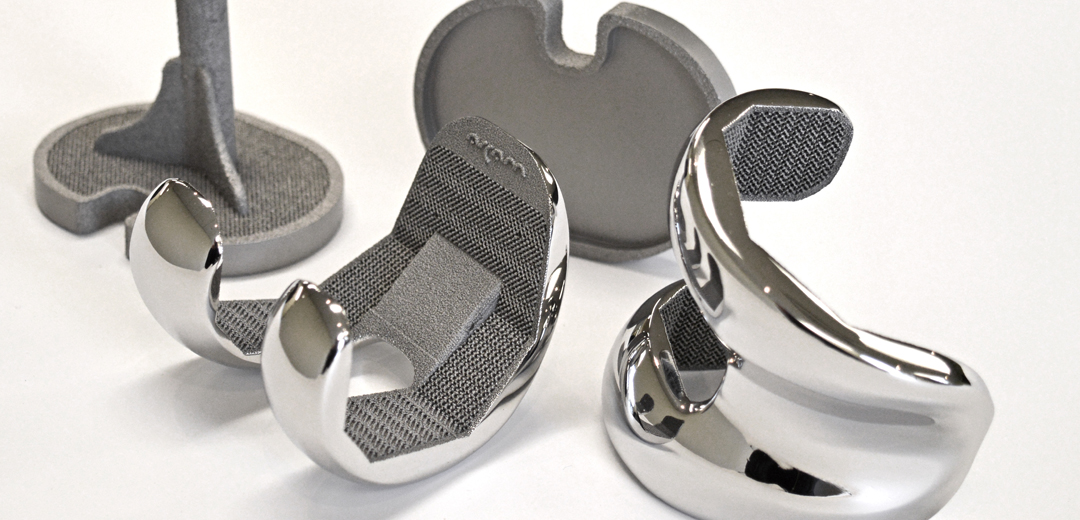

The efficiencies of additive manufacturing can offer opportunities to expand margin, but at what cost? And how can you ensure product equivalency of additively manufactured large joint implants as you transition from traditional manufacturing.

Join this webinar, hosted by GE Additive and Orchid, to learn about the materials, testing, manufacturing operations and regulatory path of additively manufactured large joints implants. The session will also explore how today’s technologies allow you to leverage the benefits of AM without sacrificing quality or performance and unlock efficiency with zero compromise.

You will also learn about…

-

The effects of additive manufacturing on material properties, strength and cleanliness

-

The 510(k) path for additively manufactured large joint implants

-

The less-talked-about complexities of additive manufacturing, such as post processes and machining, to achieve the required tolerances and performance factors

Speakers

Dan Frydryk

Advanced Lead Engineer

GE Additive

Daniel Frydryk is an Advanced Lead Engineer working in GE Additive’s Materials and Processing engineering organization. Daniel joined GE in 2017 where he spent time as a mechanical applications engineer teaching customers how to think about manufacturing in a layerwise fashion. 2019 brought Daniel back to his roots and into his current role as a materials engineer where he now focuses on titanium applications in all powder bed modalities as well as stainless steel and copper alloys for GE Additive’s binder jet products. His favorite part of the job is watching customers have the “eureka!” moment when a particular part of additive manufacturing suddenly makes sense.

Before joining GE Additive, Daniel gained experience with aerospace-grade alloys while forging titanium and nickel superalloy rotating parts for the aerospace and power generation industries. He holds undergraduate and graduate degrees in Materials Science and Engineering from Rensselaer Polytechnic Institute and Virginia Polytechnic Institute and State University (Virginia Tech), respectively.

Joseph Farinella

Quality Director, Orchid Orthopedic Solutions

With more than 14 years in the medical device and pharmaceutical industries, Joe’s passion and expertise lie in the areas of Quality Systems and Regulatory Science. He is currently responsible for quality and compliance at five of Orchid’s manufacturing facilities specializing in medical device manufacturing.

More Webinars

-

Webinar: Additive Manufacturing… Revolutionizing the Dental Industry

April 27, 2021 - 12 PM -

Webinar: Turning Metal Additive Build Failures into Positive Learning Experiences

March 31, 2021 - 12 PM -

Webinar: Binder Jetting Hard-to-Weld, Nickel-Based Superalloy RENÉ 108

March 29, 2021 - 12 PM