Highlighted Stories

Latest case study

December 07, 2023 - 12 PM EDT

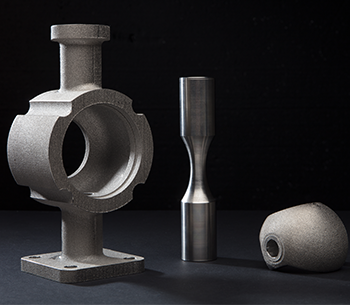

Ramén Valves: An Additive Manufacturing Pioneer in the Industry

Part of the excitement around metal additive happens when someone discovers a unique application in an industry typically dominated by casting and the machining of bar stocks. This is the case for Ramén Valves.

November 28, 2023 - 12 PM EDT

The Adventures of Pinocchio with GE Additive's Mlab

We're not gonna lie. It's pretty cool that metal additive manufacturing played a significant part in the success of Guillermo del Toro's animated version of the timeless classic Pinocchio.

October 18, 2022 - 12 PM EDT

TURN UP: Larger, Lighter Additive Parts

GE Aerospace Advanced Technology Munich-led European consortium unveils one of the largest-ever metal 3D-printed aerospace parts and demonstrates significant cost, weight and time savings

Latest case study

November 16, 2021 - 12 PM EDT

US Air Force to 3D-print parts for fighter plane

GE’s engineers are building a 3D-printed sump cover for the GE F110 engine. The sump is part of the oil lubrication system, and the sump cover is a cap —and a key part of the engine.

November 12, 2021 - 12 PM EDT

Avalign Technologies deploys EBM to drive business growth and scale in orthopedic contract manufacturing

Jeff McCaulley, CEO of Avalign Technologies, is a passionate advocate of metal AM, especially EBM, in the field for orthopedic implants, where his company is one of the fastest-growing contract manufacturers.

November 11, 2021 - 12 PM EDT

Japan’s service bureaus play critical role in driving the adoption and growth of metal additive

While metal additive technology is anticipated to grow significantly in the Japanese domestic market in coming years, it is still at an early growth stage.

November 10, 2021 - 12 PM EDT

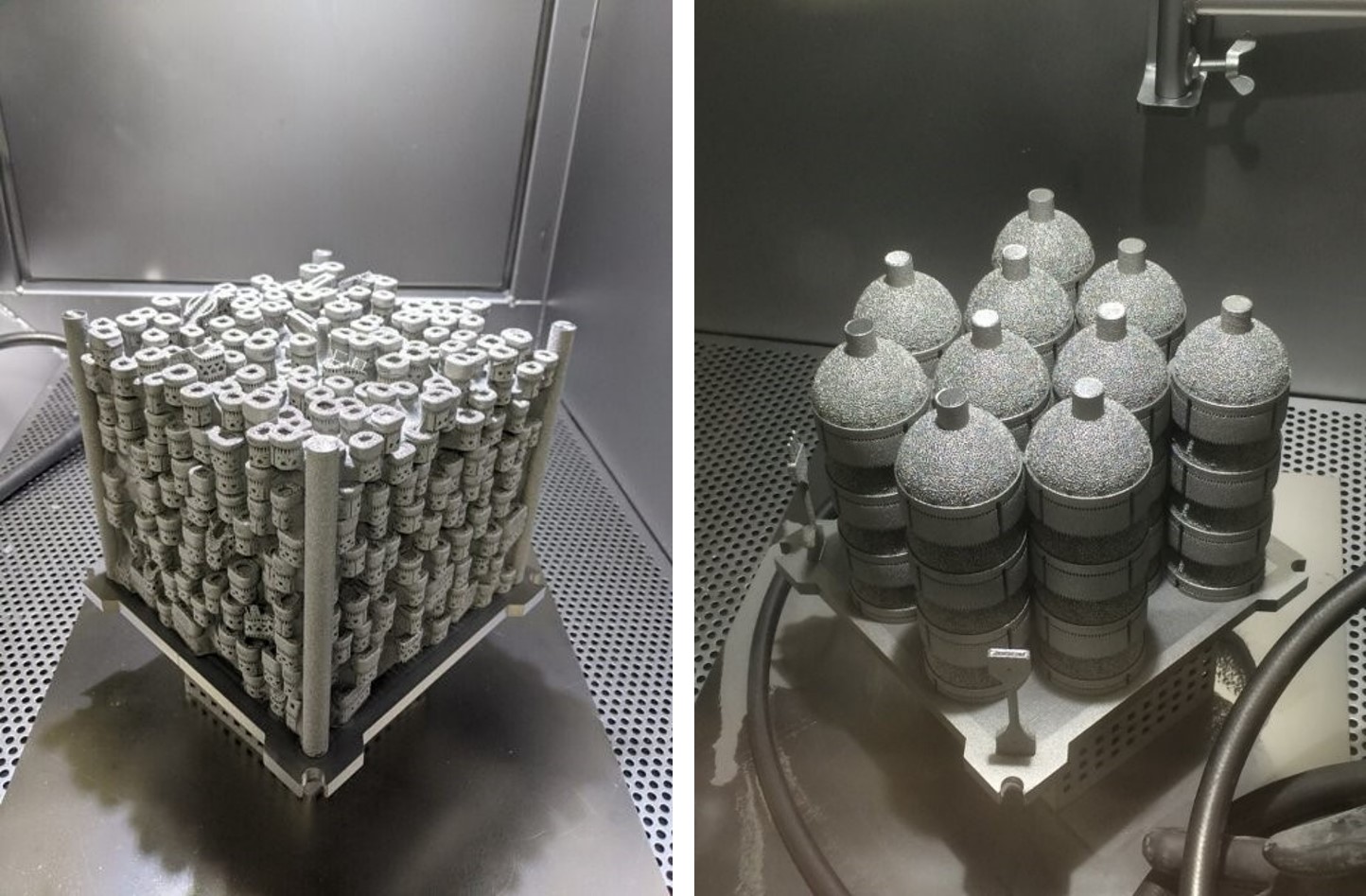

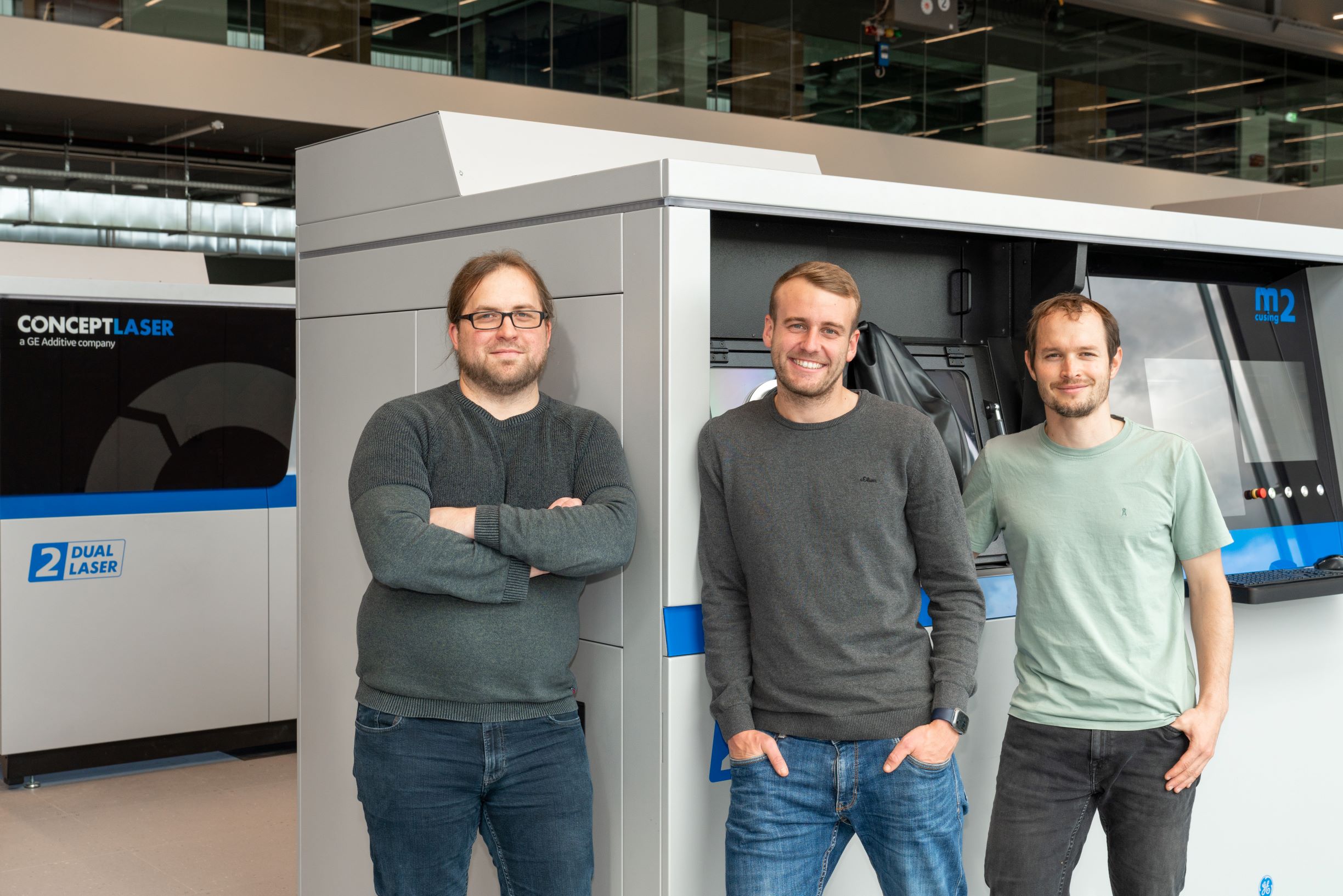

Profile: GE Additive Lichtenfels Process & Materials team

We recently caught up with the GE Additive Lichtenfels Process & Materials team to learn about their focus and recent work on aluminum parameters.

October 26, 2021 - 12 PM EDT

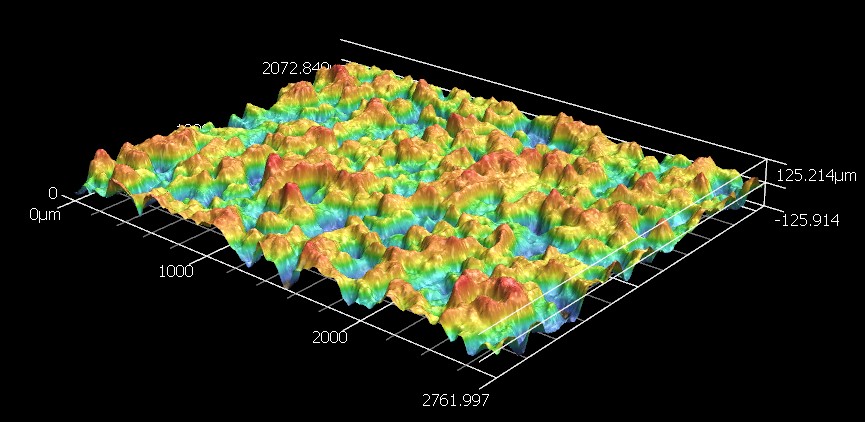

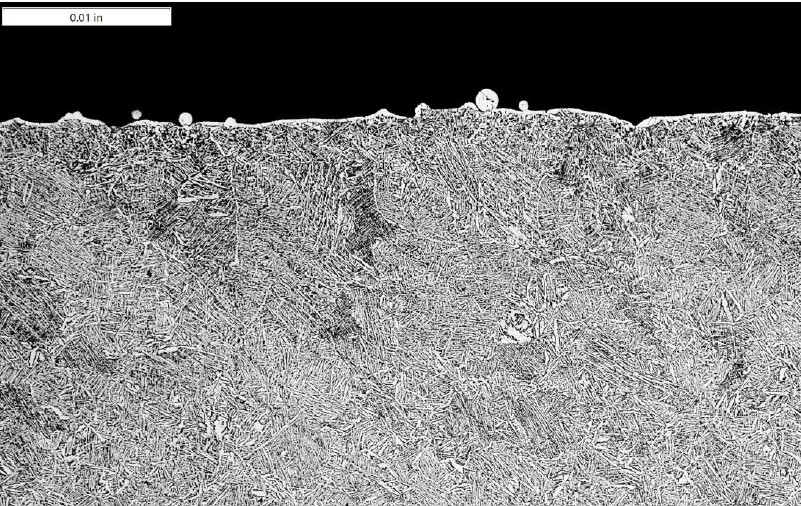

Get the Facts on… Surface Roughness

There are many aspects that can affect the performance of an additive part, one of which is the surface roughness. It is a key factor in certain mechanical properties and is driven by additive modality and process parameters…

October 19, 2021 - 12 PM EDT

Get the Facts on… Heat Treatment

Heat treatment cycles are used in the manufacturing process of functional and mission-critical parts, regardless of whether they are made by additive manufacturing or by more conventional manufacturing methods…