There's a faster path to metal additive production

No organization can expect to get and stay ahead while moving slowly. Wherever you are on the path to metal additive production, our team can help get you there faster.

Accelerated innovation

Price is still an important business differentiator for many, but often, your customers will choose whoever can serve them the quickest. Speed is often used as the most critical factor in the business world. And the quicker things move, the quicker they improve. Going faster with additive gives both you and your customers the precious gift of time.

Create a comprehensive business case and move to production – faster – with the four steps outlined in this playbook.

Let's go faster together

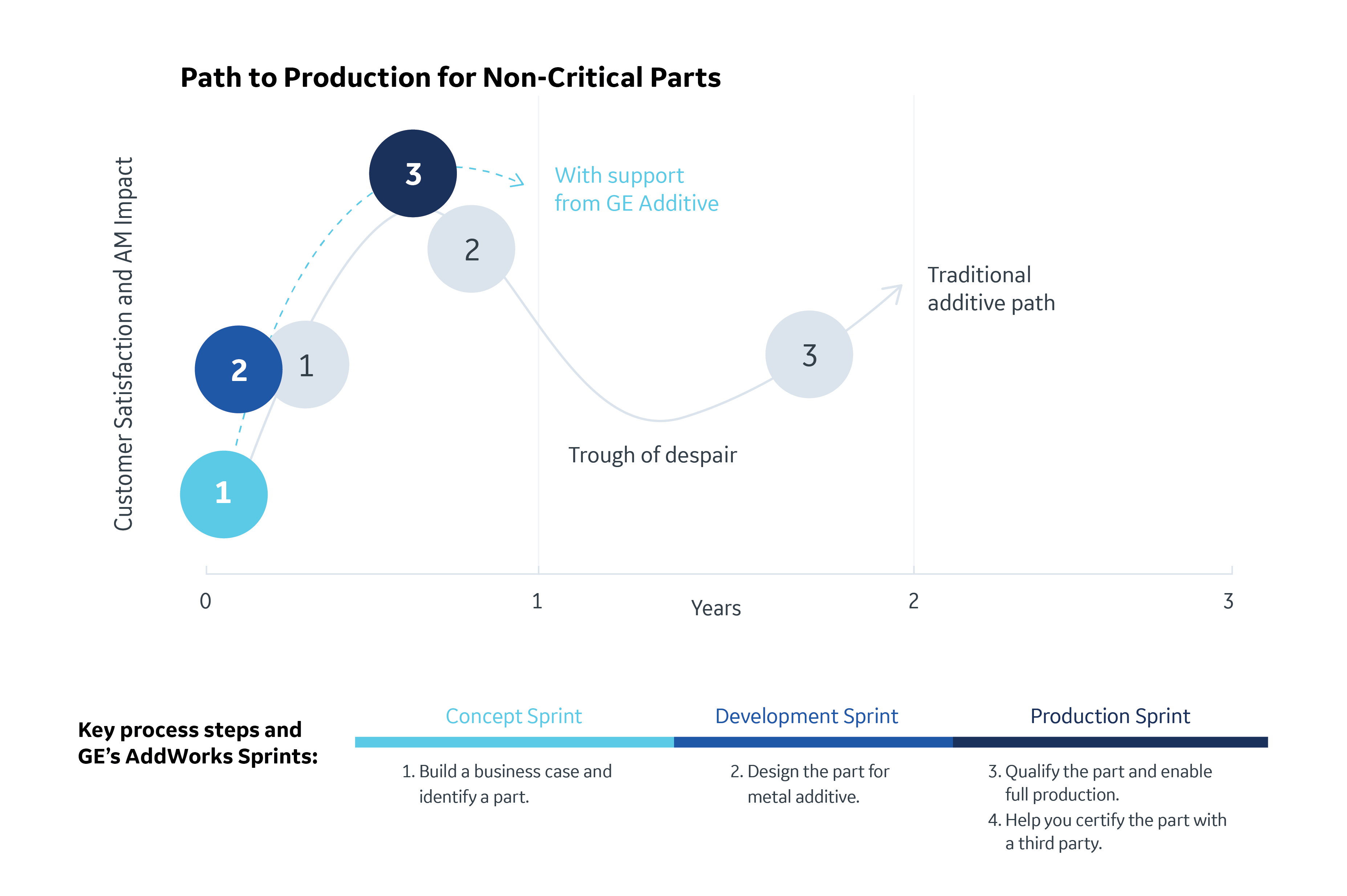

Every day our talented AddWorks™ consulting team uses its extensive AM experience to guide customers along their additive journey. We model our implementation roadmap around our internal experience with AM.

The AddWorks team works shoulder-to-shoulder with our customers, helping them use this transformative technology to change their businesses—and the future.

OUR CUSTOMERS REPORT:

- Informed decision making to shorten their capital equipment purchase cycle down to 7 months.

- We showed them how to unlock enough applications to maintain full annual capacity on two machines, on their own, in 4 months.

- High equipment utilization rates to reduce payback period and increase overall ROI.

- We taught the customer how to make critical business decisions around additive independently and cost-effectively.

Powder selection

Powder can be a significant cost driver of final part costs. Not all powders are created equal. Even if they meet the same chemical and particle size distributions, they may not act the same in the machine. For example:

- Powder morphology is an important factor. It can drive flowability, spreadability, and packing characteristics within a machine.

- Powders can drive surface roughness characteristics of final parts.

- Powders with high amounts of existing porosity within individual powder particles can make their way into final parts, which is undesirable for material performance.

AP&C powder is produced in such a way to maximize performance, minimize the impact of the above, and to drive optimal performance in machines.

Reduced financial risk

You’re ready to or have already invested lots of time and money into additive. You have your additive business case, illustrating the economic and performance benefits for your organization. But how do you qualify your selected components faster and with an increased success rate, therefore lowering your potential for investment loss?

Understanding the appropriate application of standards, guidelines, and regulations may allow your business to have a competitive advantage.

Lower costs

Going faster means shortened time to market, which translates to cost savings for your business. Working with a trusted additive leader like GE, gives you the opportunity to apply our best practices and proven methodology to solve your biggest technical and business challenges, faster and at a lower cost.

Download our playbook "Planning a successful transition to serial additive production", where we share some lessons learned on our own additive journey to help others as they take steps to shift to industrialization.