Move Over Prototyping – Additive Production is Here! 5 Tips for a Successful Transition

Metal additive technology delivers great ROI in prototyping applications..but what about production partmaking? Moving from a few prototypes to full-scale production is not a straight-forward journey. Have you struggled with deciding where to start?

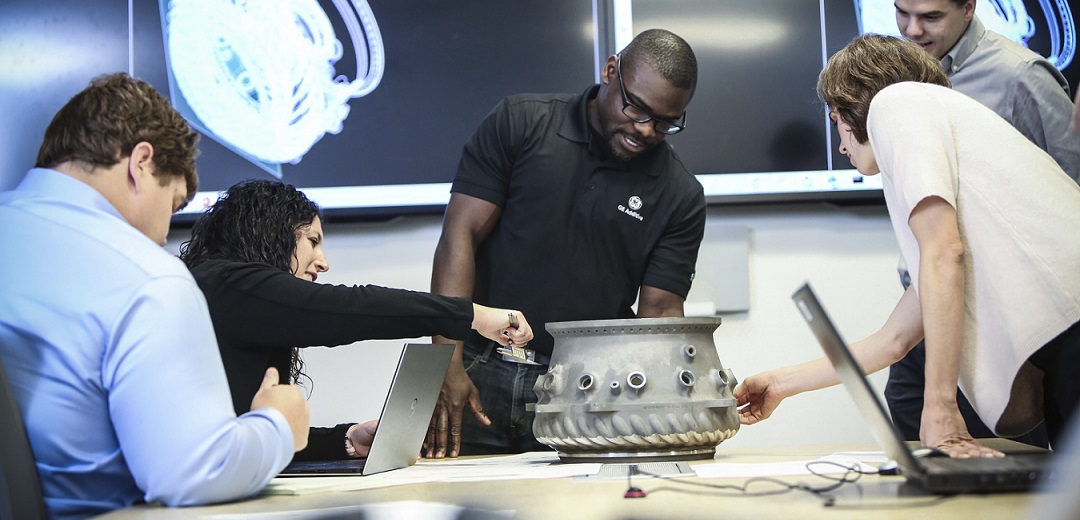

Join Steve Slusher from GE Additive AddWorks as he shares what he’s learned from helping GE and other organizations adopt additive manufacturing for full-scale production. AddWorks is GE Additive’s in-house engineering consulting team that helps companies with additive part development and production in the automotive, aviation and energy/power industries.

In this webinar, Steve will discuss:

- GE’s approach to integrating design and manufacturing to print complicated assemblies

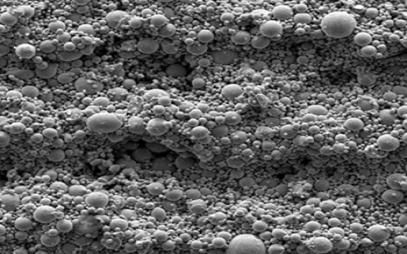

- Printing Repeatability and Process Control: Understanding and controlling the critical factors that impact variability

- Part Reliability: Defining the post processing required to ensure high-level part quality

About the Speaker:

As an Executive leader at AddWorks, Steve Slusher leads a team of design and manufacturing engineers and data scientists that partners with our customers to industrialize their additive manufacturing process. In this role, he championed the upgrades of the M2 product line and brought analytics to the forefront to improve both machine and product repeatability.

Steve has been with GE for 16 years with roles in design, testing and certification. He has led teams on several GE Aviation Commercial product lines. Since joining GE Additive a year and a half ago, Steve has established a multi-regional team to industrialize the existing laser and electron beam product line and the surrounding processes. The team has worked with both internal and external customers to help them advance their additive journey into piece part production.

PDH Certificates will be provided to all registrants that attend the live webinar for a minimum 30 minutes. Certificates will be sent by email within 72 hours after completion.