TCT Show delivers a dynamic mix of expert speakers, real world applications and innovations alongside exclusive product launches, live demonstrations and a host of exciting show feature.

Across three days, the conference and seminar program will deliver fascinating talks from a packed line-up of leading industry figures. Hear about cutting-edge applications and the latest research developments in industries such as aerospace, automotive, medical, dental, consumer and industrial product design.

Join GE Additive in booth N26 and see where additive journeys begin. Our AddWorks team will be holding live design demonstrations in our booth, the schedule is listed below. We look forward to seeing you in Birmingham!

| September 25 – 27 | AddWorks presentation schedule at TCT Birmingham Each session lasts approximately 15 minutes |

| 10 am | Key elements of an effective additive business case Many organizations new to additive experience difficulties in developing a business case for additive applications. Join this AddWorks demonstration as we take you through the business case process, so that you can understand how to develop a business case to integrate additive manufacturing into your organization. |

| 11 am | Benefits of additive design There are many applications in industry that can benefit from additive-enabled designs. Join the AddWorks team as we demonstrate various additive design capabilities. We’ll explore the benefits of these capabilities with side-by-side comparisons to traditionally manufactured equivalents. |

| 1 pm | Understanding topology optimization in additive manufacturing Additive manufacturing allows for design freedoms that remove the limitations set by traditional manufacturing methods. Engineering requirements can more directly drive the shape and design of components. Join AddWorks to learn more about how topology optimization can help you best leverage this design freedom. |

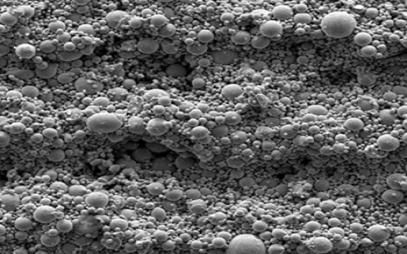

| 2 pm | Additive materials: The relationship between powder, process and properties Additive manufacturing transforms metal powder into fully dense printed metal parts. However, to reach the necessary material properties, additional post processing may be required. Join GE Additive's AddWorks team to learn more about additive post-processing techniques and how these impact material properties and microstructure. |

| 3 pm | Critical considerations in part consolidation Additive manufacturing enables the consolidation of multiple parts into one. This can enable significant reduction in assembly and supply chain costs; however, there are critical details that should be considered when evaluating an assembly for consolidation. Our AddWorks team will discuss these considerations in a live demonstration. |