For this year’s Met Gala, Zac Posen has collaborated with GE Additive and Protolabs to showcase the creative power of 3D printing.

What might seem like an unlikely collaboration of design engineers and Zac Posen - one of the fashion industry's leading lights, at the forefront of innovation - in fact makes complete sense when you consider the transformative impact 3D printing is having on our everyday lives.

Over the past six months, Zac Posen’s design team, together with design engineers from GE Additive and additive manufacturing experts from Protolabs have explored 3D design and printing techniques to create a range of sculptural garments and accessories inspired by the concept of freezing natural objects in motion.

Rose Gown

Zac Posen had a vision of creating a dress based on the form and natural beauty of a rose. The AddWorks team worked alongside Zac to understand his vision and his way of designing. Knowing Zac and his team are used to a very iterative and fluid design process, the team came up with a solution that featured a modular design, allowing him to make changes after it had been printed. The rose gown consists of a total of 21 petals. The petals are fastened in place by a modular cage, which was printed in Titanium (Ti-64) due to its high strength and low weight properties. The modular cage was printed using electron beam melting (EBM) technology on GE Additive's Arcam EBM Q20plus machine. The petals are made of Accura Xtreme White plastic and printed on a stereolithography (SLA) machine by our partners at Protolabs. The printing and finish of the rose gown took over 1,100 hours and was printed in North Carolina.

Clear Bustier

The clear bustier started with Zac’s creative approach of draping on a mannequin. The AddWorks team took that design direction and through a combination of freehand work in CAD and laser scan data, they were able to create something that would not have been achievable in fabric. Protolabs manufactured the bustier out of Somos Watershed XC 11122 plastic and printed on a stereolithography (SLA) machine. It is finished by wet hand sanding and sprayed with a clear coat to give it a glass appearance. The printing and finish of the bustier took over 200 hours and was printed a Protolabs facility in Germany.

Palm Leaf

Leveraging rapid prototyping to find the perfect fit and design, the pearlescent purple palm leaves were created to be draped over the shoulders and attached to the gown at the neckline. The AddWorks team used a blend of freehand design and laser scanning in CAD based on inspiration provided by Zac. The palm leaves are made of Accura 60 plastic and printed on a stereolithography (SLA) machine. The structure is finished with pearlescent purple paint (Pantone 8104C) and holds the custom Zac Posen water colored tulle gown at the clavicle. The printing and finish of the palm leaves took over 56 hours and was printed in North Carolina by Protolabs.

Headpiece

Zac Posen’s team provided rough sketches of a shape they were envisioning as a headpiece. The AddWorks team recreated it in CAD, and in very close collaboration with Zac’s team iterated and evolved the shape and structure. The intricate printed vine headpiece with leaf and berry embellishments is printed as a single piece and made of Nylon 12 plastic and printed on a stereolithography (SLA) machine. The headpiece is finished with brass plating. The printing and finish of the headdress took over 22 hours and was printed in North Carolina by Protolabs.

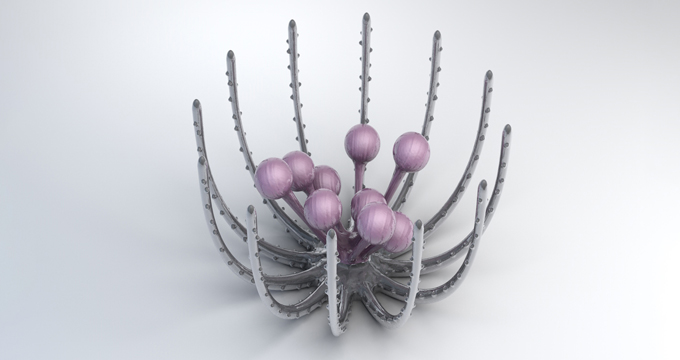

Sea urchin embroidery

This gown includes 408 delicately printed embroidery pieces, inspired by sea urchins, which were hand sewn onto the dress. The AddWorks team took Zac's inspiration and sketches and recreated them in CAD. They were able to iterate and print several different sizes to meet Zac's desired look. The embroidery pieces were made of Accura 5530 plastic and printed on a stereolithography (SLA) machine. The embroidery was vacuum metalized, and center painted with Pantone 8081 C. The printing and finish of the embroideries took over 160 hours and was printed in North Carolina by Protolabs.